One-time blasting method for large section of rock roadway

A one-time, large-section technology, applied in the field of blasting, can solve problems affecting blasting effects, threats to safety production, and slow excavation speed, so as to improve blasting safety, prevent technical throwing of shots, and reduce the size of rock blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

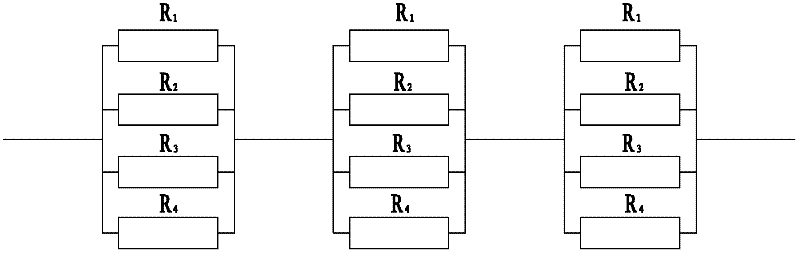

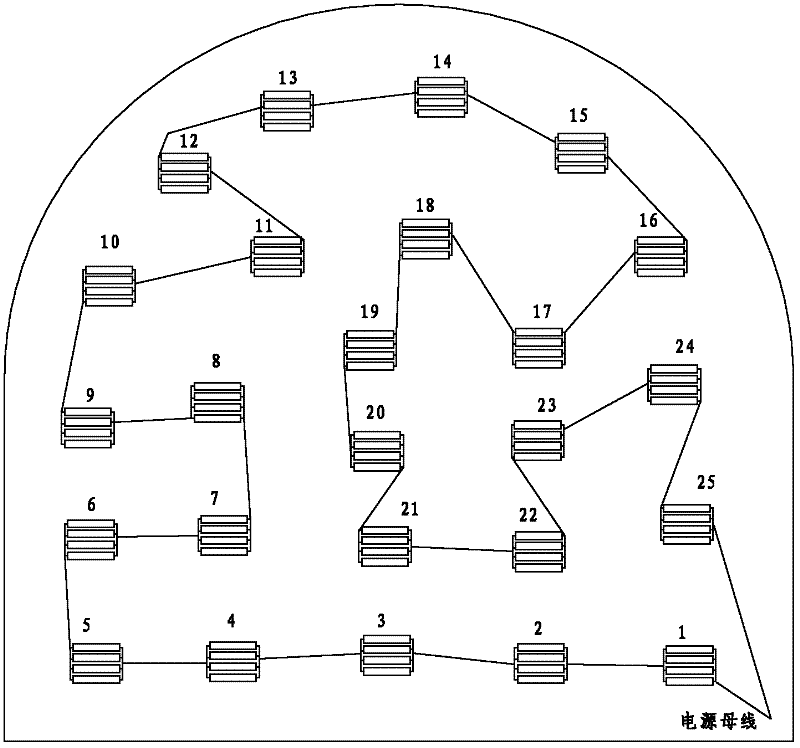

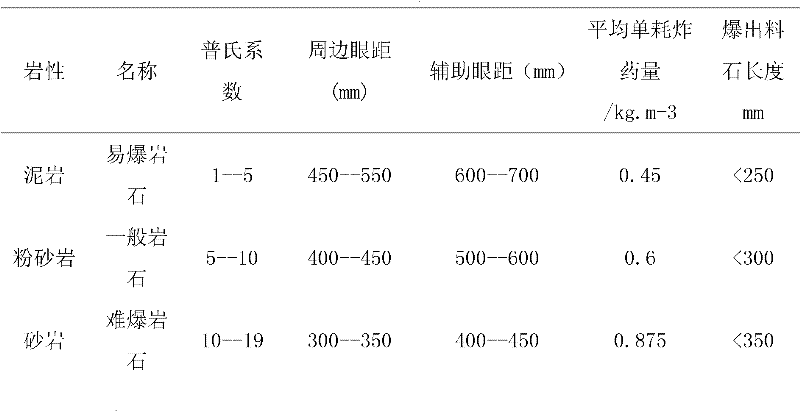

[0063] see figure 1 , 2 , when the lithology of the rock roadway in the mine section is 1-5, the lithology is mainly mudstone and explosive rock, the suitable roadway section is 13-15 square meters, the number of detonators used is 90-110, and the type of blasting detonator is selected as iron Detonator, the length of the foot line is 3 meters, and the practical resistance value of the detonator is 4.5-5.5ζ;

[0064] Determine the technological parameter of the blast hole as the drill diameter The depth of the blasting hole is 2.4m, the diameter of the explosive is 27mm, and the length is 400mm or 250mm. The distance between the holes around each blasting hole is 450-550mm, and the distance between the auxiliary holes is 600-700mm. Drilling is carried out;

[0065] According to the type, model and quantity of explosives determined by each blast hole, uncoupled charge is used to fill explosives, 2 rolls per hole for peripheral blast holes, 300g per roll, 3 rolls per hole for...

Embodiment 2

[0070] see figure 1 , 2 , when the lithology of the rock roadway in the mine section is 5-10, the lithology is mainly siltstone, which is relatively difficult to blast, and the suitable roadway section is 16-20 square meters. The length is 3 meters, and the resistance value of the practical detonator is 4.5-5.5ζ;

[0071] The process parameters for determining the blast hole are: peripheral hole and auxiliary hole drilling diameter Cutting hole diameter The depth of the blast hole is 2.4m. The peripheral eye and auxiliary eye use water gel explosives with a diameter of 27mm and a length of 400mm. The cutting hole uses water gel explosives with a diameter of 35mm and a length of 250mm. The spacing is 500-600mm;

[0072] According to the type, model and quantity of explosives determined by each blast hole, uncoupled charge is used to fill explosives, 2 rolls per hole for peripheral blast holes, 300g per roll, 3 rolls per hole for auxiliary blast holes, 250g roll per hole, ...

Embodiment 3

[0077] see figure 1 , 2 , when the lithology of the rock roadway in the mine section is 10-19, the lithology is mainly medium-fine sandstone, which is relatively difficult to blast, and the suitable roadway section is 18-22 square meters. The line length is 3 meters, and the practical detonator resistance value is 2.8-3.3ζ;

[0078] The process parameters for determining the blast hole are: peripheral hole and auxiliary hole drilling diameter Cutting hole diameter The depth of the blast hole is 2.4m. The peripheral eye and auxiliary eye use water gel explosives with a diameter of 27mm and a length of 400mm. The cutting hole uses water gel explosives with a diameter of 35mm and a length of 250mm. The spacing is 400-450mm;

[0079] According to the type, model and quantity of explosives determined by each blast hole, uncoupled charge is used to fill explosives, 2 rolls per hole for peripheral blast holes, 300g per roll, 3 rolls per hole for auxiliary blast holes, 250g roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com