Hydraulic support vertical tooling

A hydraulic support and tooling technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low labor intensity, difficulty in controlling the assembly of hydraulic support inserts and tail beams, etc., to reduce labor intensity and reduce potential safety hazards Probability of occurrence, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described.

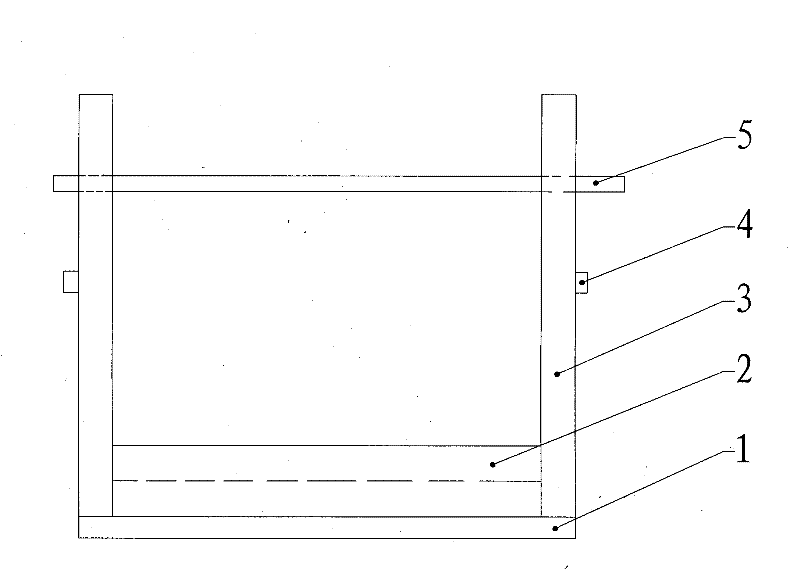

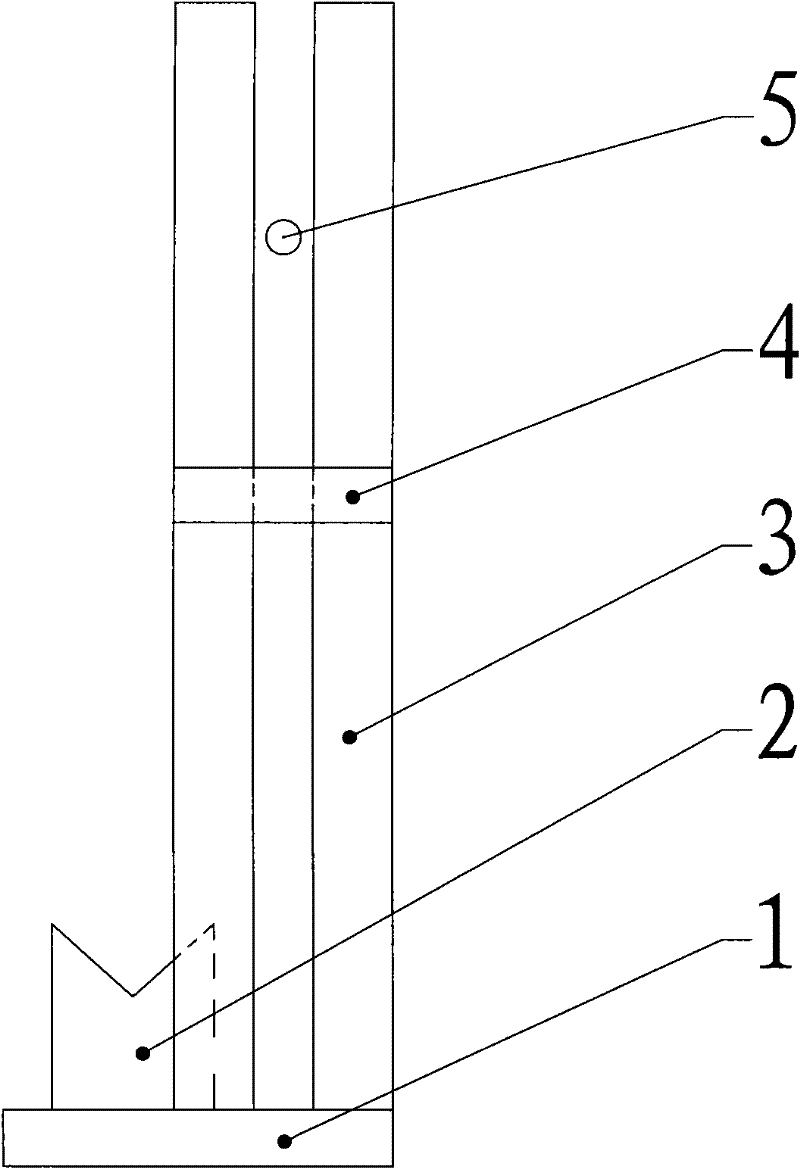

[0026] like Figure 1-Figure 2 As shown, the hydraulic support vertical tooling of the present invention mainly includes: a bottom steel plate 1, a V-shaped groove 2, a column 3, a rib plate 4, a horizontal shaft 5, etc., and the specific structure is as follows:

[0027] A V-shaped groove 2 is welded on the bottom steel plate 1, and a pair of columns 3 are respectively welded on both ends of the V-shaped groove 2 and on the bottom steel plate 1. There is a distance between each pair of columns 3, and each pair of columns 3 is connected by a welding rib plate 4. The shaft 5 is arranged between two pairs of uprights 3 , and the distance between each pair of uprights 3 allows the horizontal shaft 5 to move vertically on the ribs 4 .

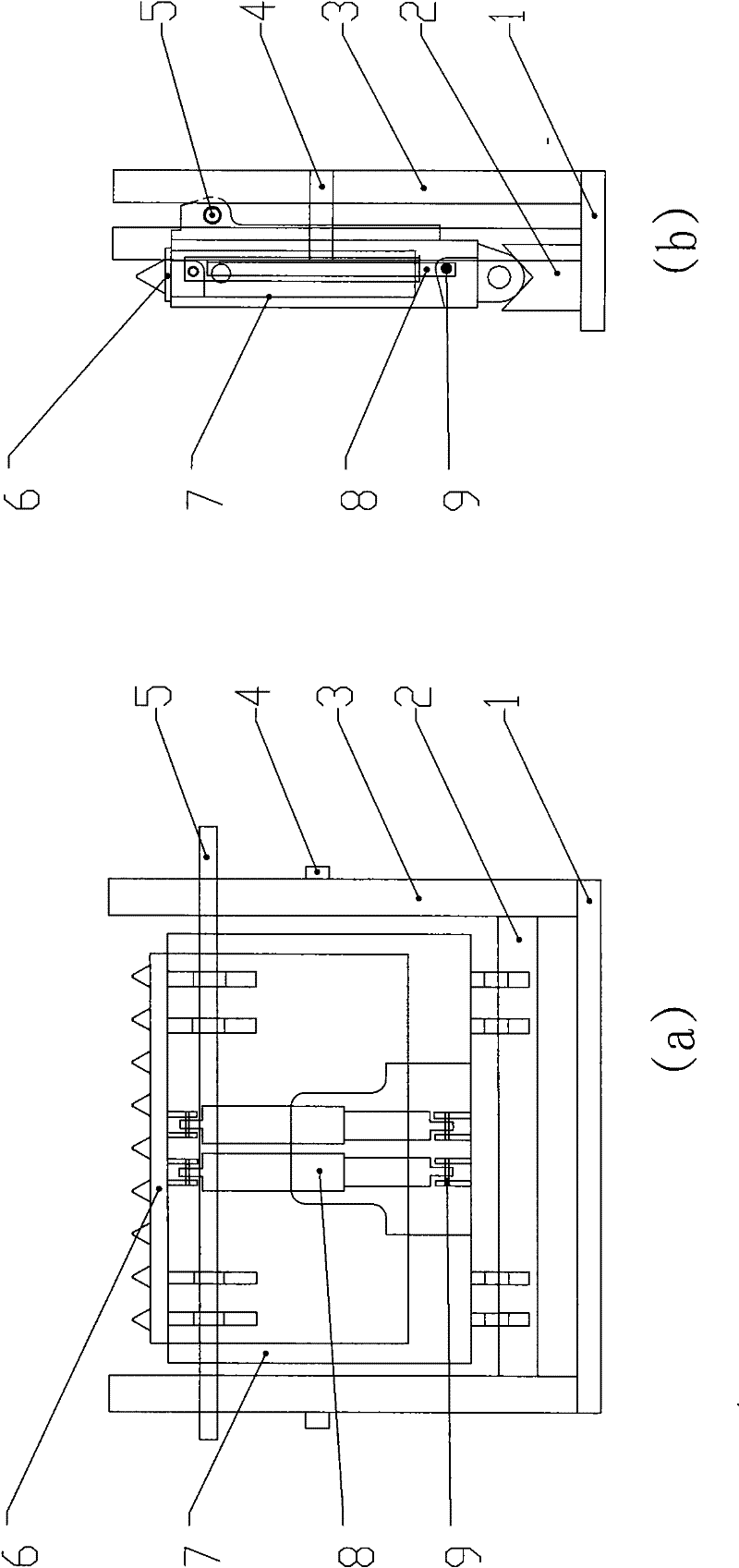

[0028] like image 3 Shown in (a)-(b), the present invention is used when the tail beam 7 and the flashboard 6 of the roof coal caving hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com