Well liner segments for in situ petroleum upgrading and recovery, and method of in situ upgrading and recovery

A liner and upgrading technology, applied in drilling pipe, casing, earthwork drilling and production, etc., can solve the problems of high space velocity and short residence time of gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

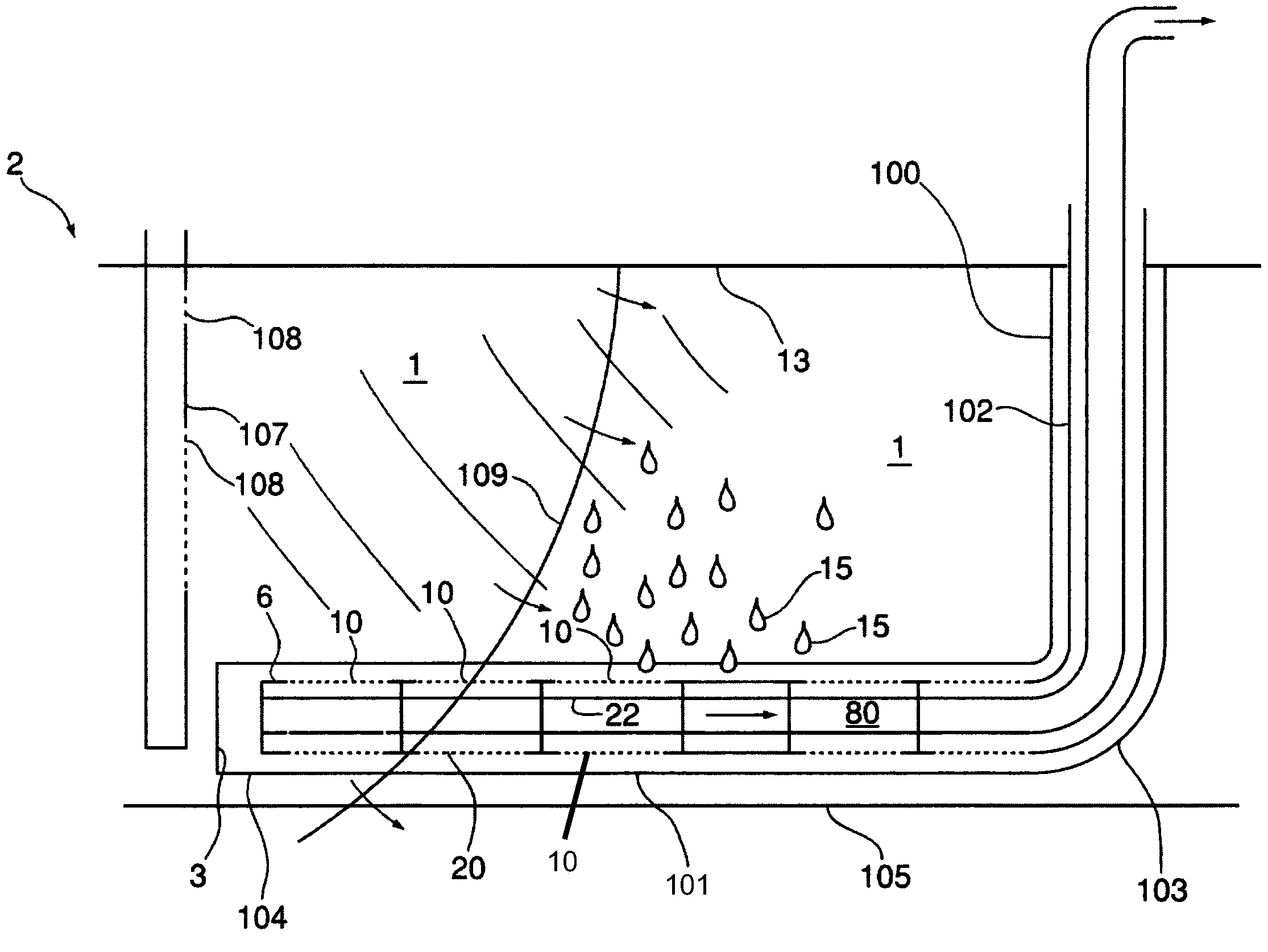

[0060] figure 1 Shown is a schematic diagram of an in-situ hydrocarbon recovery system 2 for improved recovery of hydrocarbons from a hydrocarbon-bearing formation 1 utilizing several elongated well liner segments 10 of the present invention within its horizontal wellbore 3 .

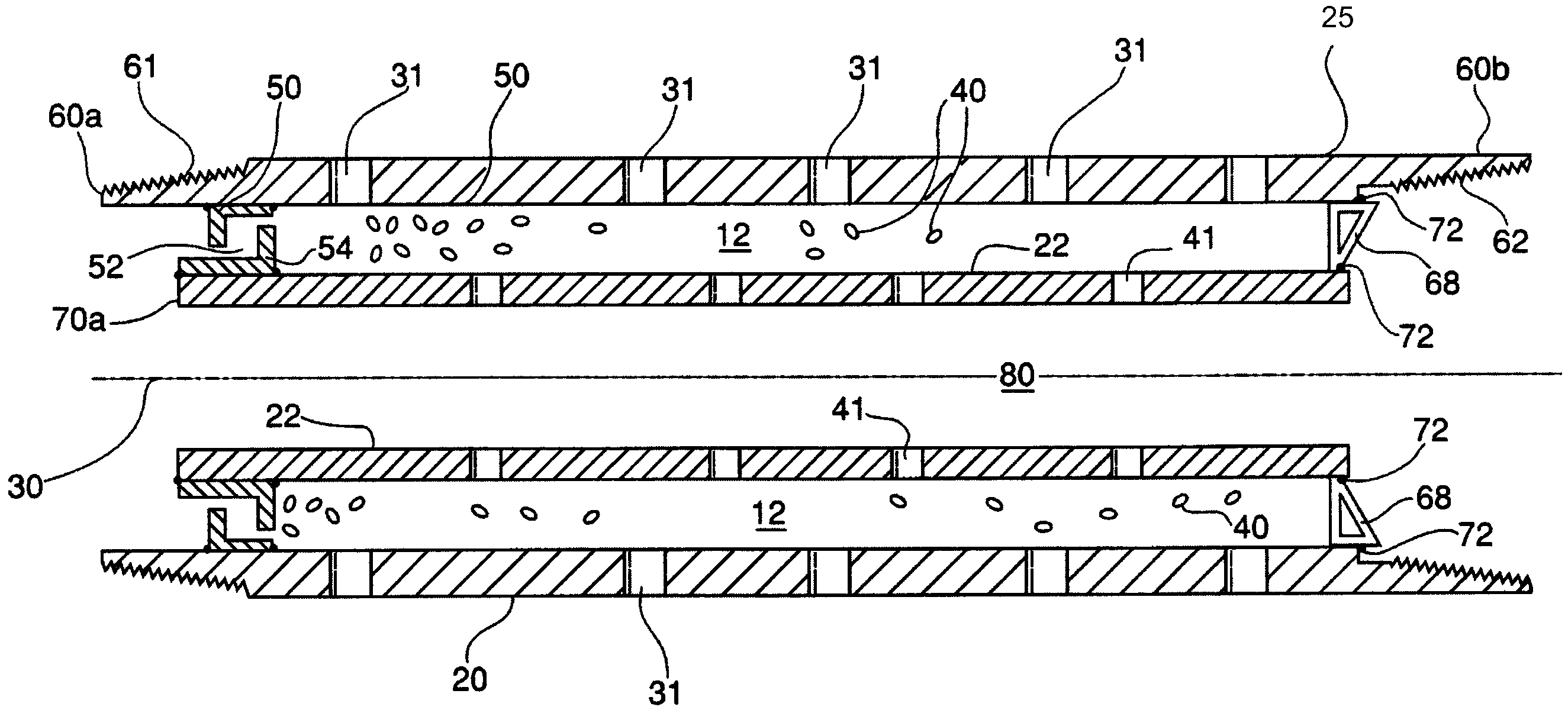

[0061]This hydrocarbon recovery system 2 is adapted to direct hydrocarbons, in particular viscous oil 15 discharged from the hydrocarbon formation 1 during the process of this hydrocarbon recovery system 2, through the catalyst-filled interstitial space 12 within each well liner segment 10, for subsequent recovery to the surface 13.

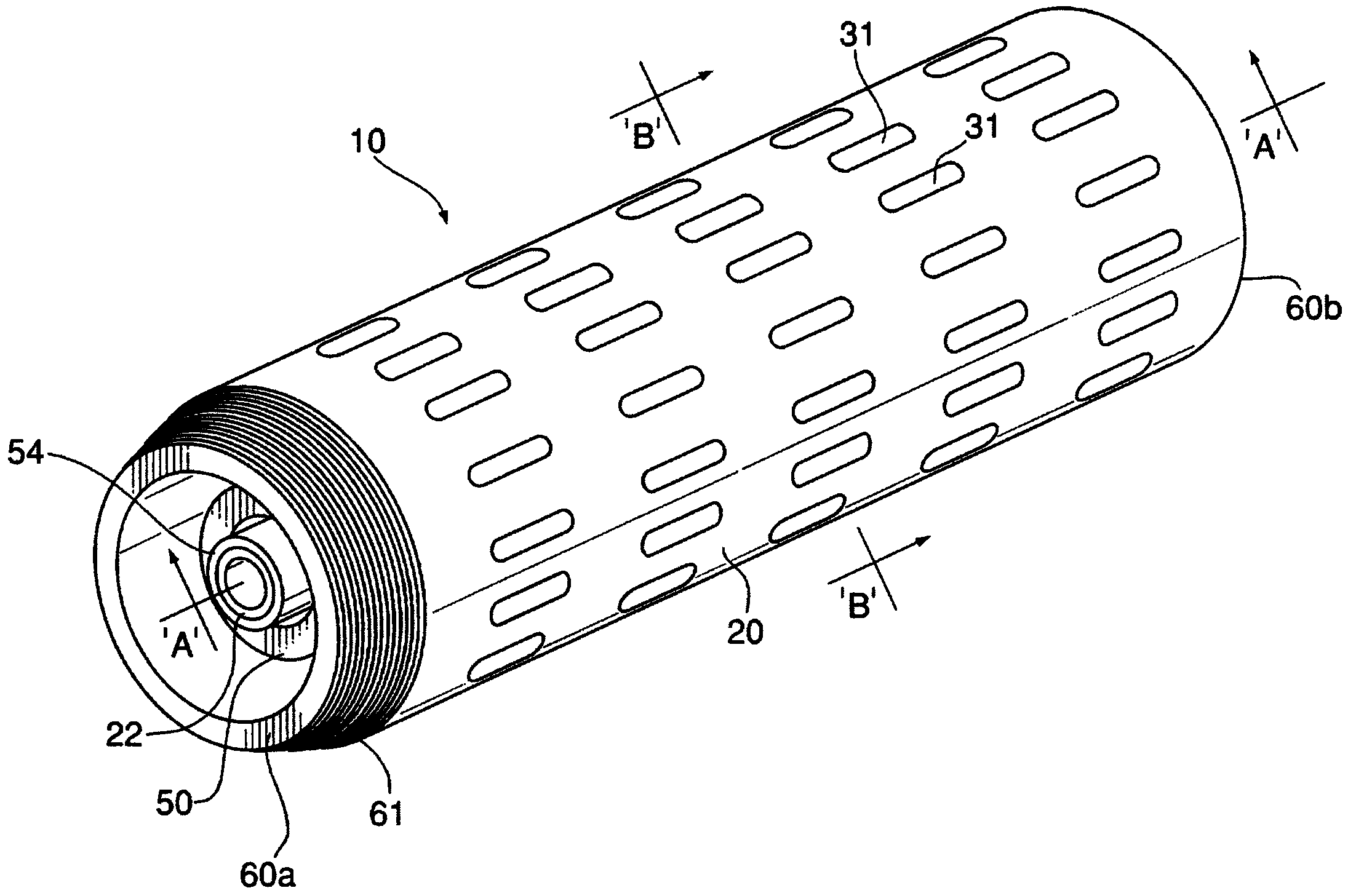

[0062] Illustrated are several well liner segments 10 of the present invention, each of which is twistably coupled to an adjacent other well liner segment 10 so as to form a well liner segment for use in an in situ hydrocarbon recovery process as shown in figure 1 Well liner in 6.

[0063] In operation, oil 15 heated by in situ combustion or alternatively by steam assis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com