Quickly assembled and disassembled convenient joint

A convenient and fast technology, used in mechanical equipment, couplings, etc., can solve the problems of high requirements for installation personnel, low efficiency, high labor intensity, etc., and achieve good leak-proof effect, maintain roundness, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

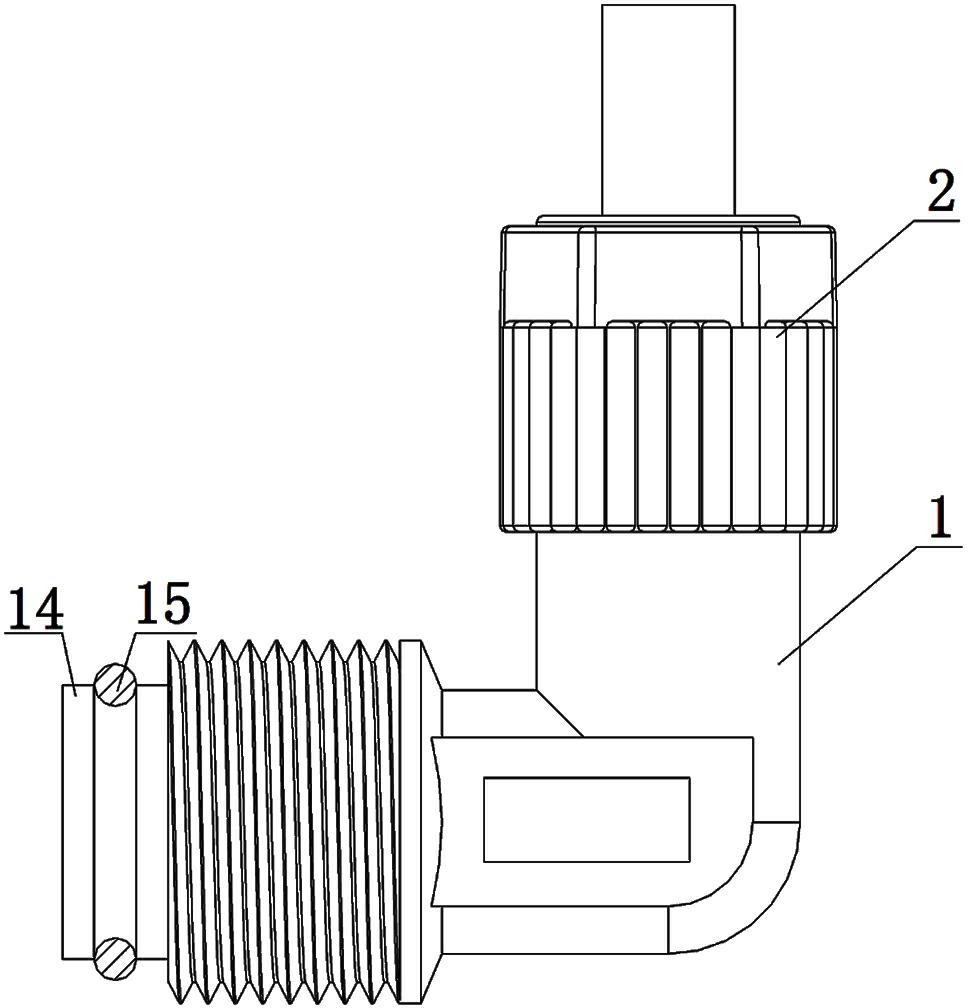

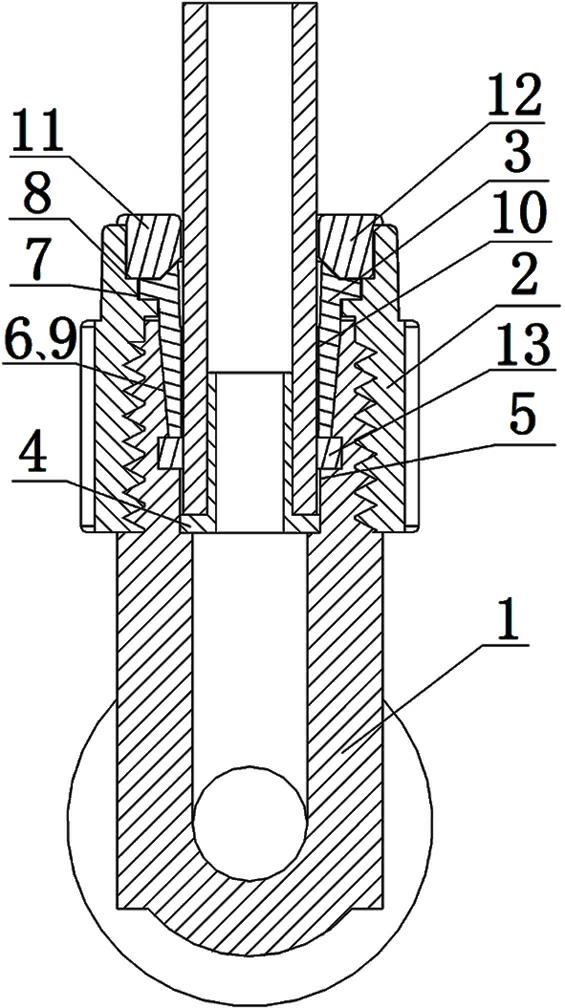

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a quick loading and unloading convenient joint, which includes a 90° elbow joint 1, a locking nut 2, a movable pawl 3 and a pipe clamp 4, and both ends of the 90° elbow joint 1 are provided with external threads, 90° One end of the elbow joint 1 is provided with a pipe body connection port 5, the outside of the pipe body connection port 5 is equipped with a lock nut 2, the inner wall of the pipe body connection port 5 is provided with an inclined cone surface A6, and the lock nut 2 One end is provided with an internal thread matching the 90° elbow joint 1, and the outer wall of this end of the lock nut 2 is provided with a straight grain pattern, and the length of the part of the lock nut 2 processed with the straight grain pattern is the length of the lock nut 2 Half of the overall length, on the inner wall of the other end of the lock nut 2, there are two adjacent annular grooves from the end, which are groo...

Embodiment 2

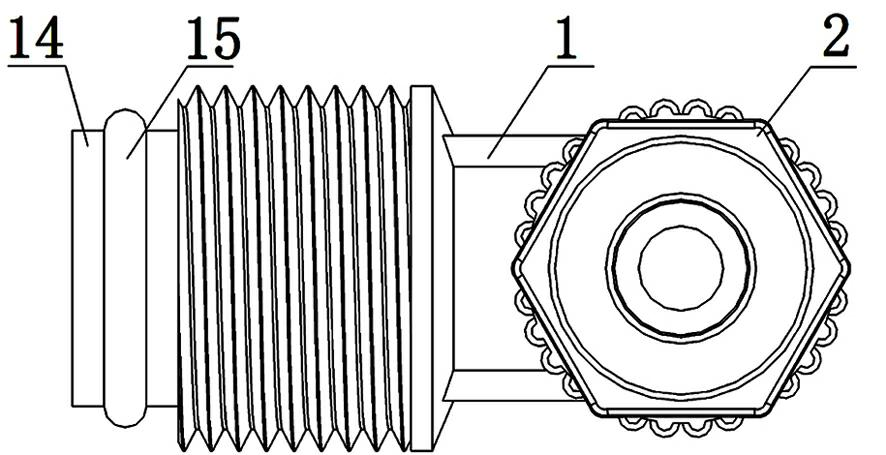

[0027] Embodiment 2: as Figure 4 As shown, a quick assembly and disassembly convenient joint, which includes a direct joint 1, a locking nut 2, a movable pawl 3 and a pipe clip 4, both ends of the direct joint 1 are provided with external threads, and one end of the direct joint 1 is provided with The pipe body connection port 5, the outside of the pipe body connection port 5 is equipped with a lock nut 2, the inner wall of the pipe body connection port 5 is provided with an inclined tapered surface A6, and one end of the lock nut 2 is provided to match the direct joint 1 The inner thread of the lock nut 2 is provided with a straight pattern on the outer wall of this end, the length of the part of the lock nut 2 processed with the straight pattern is half of the overall length of the lock nut 2, and the other end of the lock nut 2 On the inner wall of the inner wall, there are two adjacent annular grooves starting from its end, which are respectively groove A7 and groove B8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com