Multipurpose wrench

A shell and sleeve technology, applied in the field of multi-purpose wrenches, can solve the problems of poor stability, detachment, slipping, etc., and achieve the effects of comprehensive functions, simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The multipurpose wrench of the present invention will be further described in detail through specific examples below.

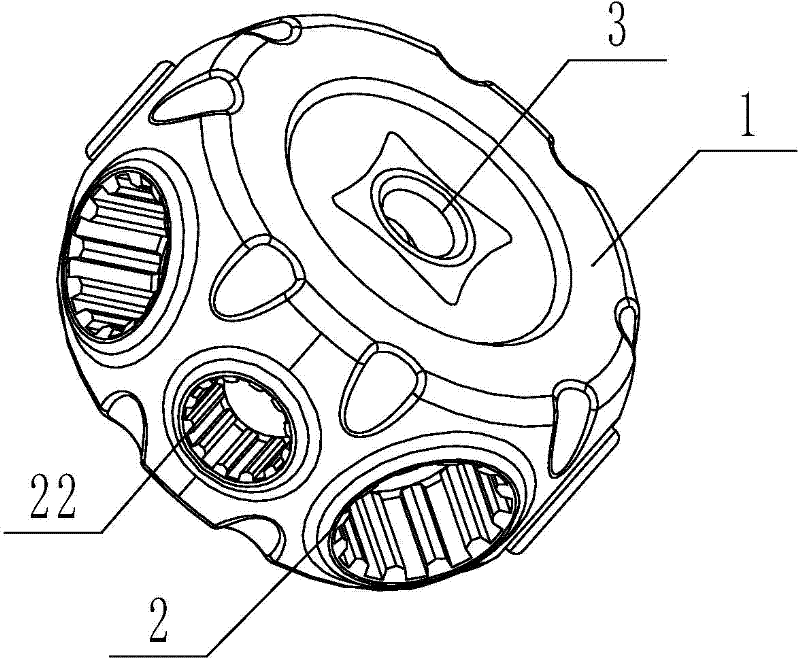

[0015] like figure 1 , figure 2 As shown, the multi-purpose wrench includes a hollow circular shell 1, and the peripheral wall of the shell 1 is provided with eight sleeve holes 2 toward the center of the circle, and the eight sleeve holes 2 are hexagonal slot holes 21 or spline holes 22 of different sizes. , to be suitable for use with hexagonal screws or nuts of different sizes, eight sleeve holes 2 are evenly distributed along the circumferential direction of the housing, and the inner ends of the sleeve holes 2 communicate with each other. The casing 1 is provided with a booster rod hole 3 penetrating through the two side walls. The number of sleeve holes 2 can be changed arbitrarily according to actual needs, and all belong to the protection category of the present invention. The housing 1 can be integrally cast, and a layer of rubber can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com