Coffee machine

A technology for coffee machines and coffee beverages, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., which can solve problems such as high energy consumption, expensive structure, and prone to accidents, and achieve cost-saving and space-saving effects

Active Publication Date: 2011-11-16

STEINER WEGGIS AG

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Such a device is expensive in construction and also has a relatively high energy consumption due to the separate heating elements for preparing coffee on the one hand and hot milk or milk froth on the other hand, especially for multiple applications in succession flow heating device

Accidents are therefore more prone to accidents, as empirically milk can easily stick in the pipes of continuous heating units

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

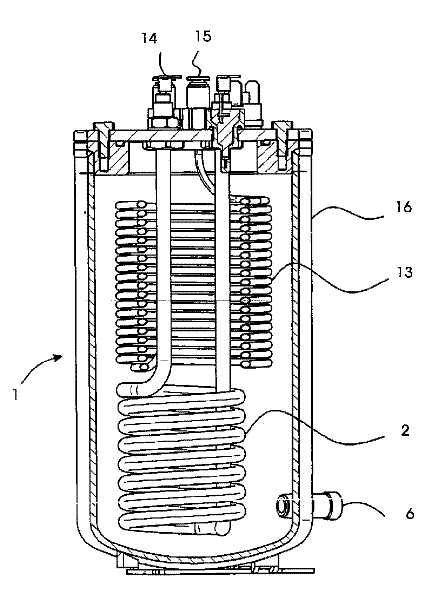

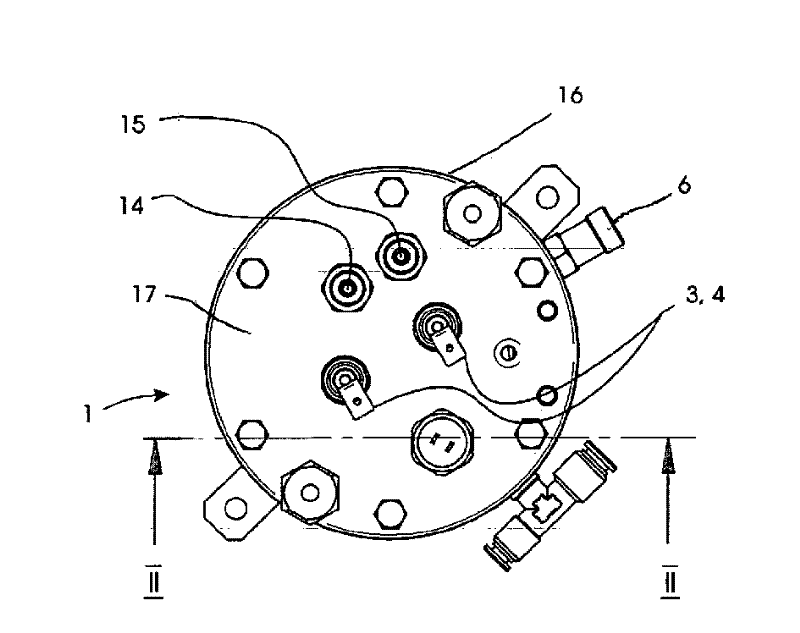

The invention relates to a coffee machine comprising a boiler (1) for producing hot water and steam for the preparation of coffee or coffee-containing beverages. A coiled tubing (13) is located in the boiler for producing hot milk or milk froth. Thus, no separate heating element is required for producing the hot milk or milk froth, as the milk or milk froth is heated by the water heated in the boiler for preparing the coffee. The coiled tubing (13) is connected alternately to a milk container (8) and a rinsing water source (25), so that potential milk residue is flushed out from the coiled tubing (13) after each milk heating process. A predetermined amount of milk or rinsing water is fed to the coiled tubing (13) by a pump (10). Thus the milk and rinsing water usage is optimized and the energy consumption is reduced.

Description

technical field [0001] The invention relates to a coffee machine for preparing coffee drinks or milk drinks with a boiler for generating hot water and steam. Background technique [0002] Such coffee machines are known in various implementations. Thus, for example, EF 0 761 150 describes a coffee machine which is provided with an outlet tap for brewed coffee and an outlet tap for drawing hot water or steam. Naturally, multifunctional devices are often required in use, which, in addition to coffee, also produce hot or cold milk or milk froth. For this it requires two different units, namely one for producing coffee and the other for producing milk or milk froth. Such a device is expensive in construction and also has a relatively high energy consumption due to the separate heating elements for preparing coffee on the one hand and hot milk or milk froth on the other hand, especially for multiple applications in succession Flow heating device. Accidents are therefore more p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47J31/44

CPCA47J31/4485A47J31/54

Inventor A.斯泰纳

Owner STEINER WEGGIS AG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com