Manufacturing method of maintenance-free motorcycle battery lead terminal structure

A manufacturing method and technology of lead terminals, which are applied to structural parts, battery pack parts, circuits, etc., can solve the problems of battery terminal ignition, cumbersomeness, and increased operation difficulty, so as to avoid easy loosening, easy installation, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

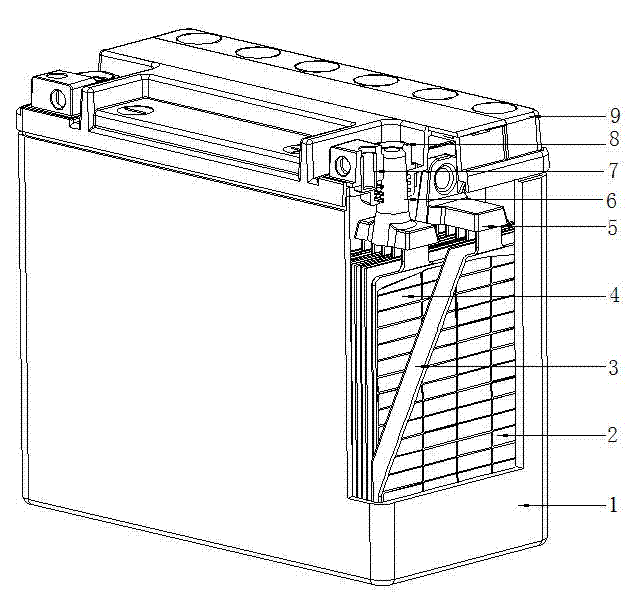

[0013] Such as figure 1 As shown, the maintenance-free motorcycle battery includes a battery case 1, a battery cover 9, an electrolyte, an electrode group, and a lead terminal 8. The manufacturing method is as follows: firstly, the nut 7 is directly poured into the mold cavity of the lead terminal fixed by high temperature The lead liquid is cast and formed into the lead terminal 8, and then the lead terminal is fixed in the cavity of the battery cover mold and formed into the battery cover 9 through high-temperature injection molding; secondly, the negative electrode plate 2, the separator plate 3, and the positive electrode plate 4 are arranged at intervals and cast-welded to form a battery cover. group, welding the busbar 5 on the pole group; then, casting and welding on the busbar 5 to directly form the pole 6; then, the battery case 1 and the battery cover 9 are heat-sealed so that the pole 6 and the lead terminal 8 are matched, and are welded by acetylene welding The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com