Method for preparing polyaluminium chloride ferric flocculant by using municipal sewage sludge

A technology of polyaluminum chloride and municipal sludge, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption in incineration, secondary pollution, environmental pollution, etc. Achieve the effect of realizing resource utilization and comprehensive utilization, reducing processing cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

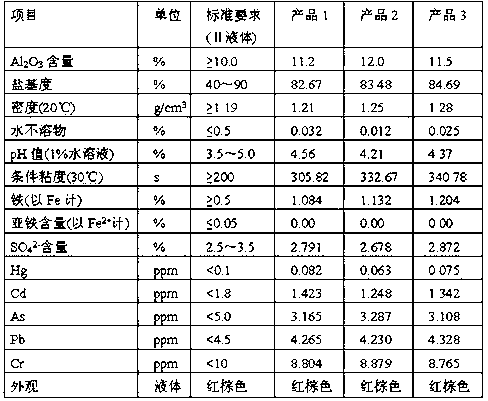

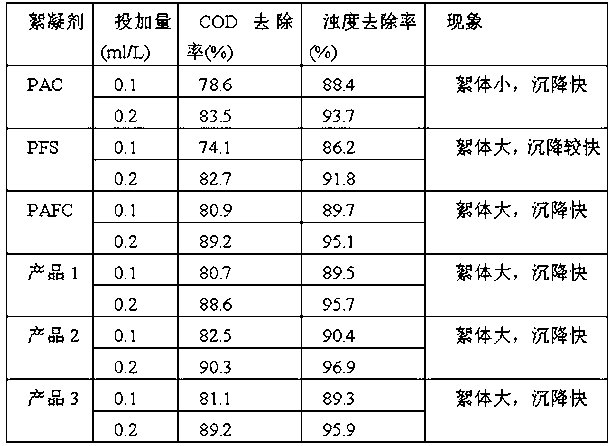

Embodiment 1

[0030] Put the sludge from the urban sewage treatment plant into the hydrothermal reactor, add hydrogen peroxide with a concentration of 30% (mass percentage), the amount of hydrogen peroxide added is 0.05-0.06g / L, and the Under pressure, heat to 135-140°C, keep the temperature for hydrothermal reaction for 3 hours; after the reaction, let it stand for 30 minutes, wait for solid-liquid separation, and filter to obtain filter residue; weigh 100g of filter residue, add 350mL industrial hydrochloric acid for acid dissolution, at 90°C After fully acid-dissolving, add 200mL of water and 3mL of iron-containing hydrochloric acid waste liquid with an iron content of 1% to 20%, raise the temperature to 80°C, add 6.8g of calcium aluminate powder, 0.03g of sodium chlorate, 0.1g of sodium sulfide was reacted at 95°C for 2.5 hours; cooled and aged for 24 hours, and filtered to obtain a reddish-brown transparent liquid product 1.

Embodiment 2

[0032] Put the sludge from the urban sewage treatment plant into the hydrothermal reactor, add hydrogen peroxide with a concentration of 30% (mass percentage), the amount of hydrogen peroxide added is 0.06-0.07g / L, and the Under pressure, heat to 145-150°C, keep the temperature for hydrothermal reaction for 2.5 hours; after the reaction, let it stand for 30 minutes, wait for solid-liquid separation, and filter to obtain filter residue; weigh 100g of filter residue, add 380mL industrial hydrochloric acid for acid dissolution, and dissolve at 95 React at ℃ for 1 hour; after fully acid-dissolving, add 250mL of water and 4mL of iron-containing hydrochloric acid waste liquid with an iron content of 1% to 20%, raise the temperature to 75℃, add 8.7g of calcium aluminate powder, 0.05g of sodium chlorate, 0.2g of sodium sulfide was reacted at 98°C for 2.5 hours; cooled and aged for 20 hours, and filtered to obtain reddish-brown transparent liquid product 2.

Embodiment 3

[0034] Put the sludge from the urban sewage treatment plant into the hydrothermal reactor, add hydrogen peroxide with a concentration of 30% (mass percentage), the amount of hydrogen peroxide added is 0.04-0.05g / L, and the Under pressure, heat to 135-140°C, keep the temperature for hydrothermal reaction for 4 hours; after the reaction, let it stand for 60 minutes, wait for solid-liquid separation, and filter to obtain filter residue; weigh 100g of filter residue, add 300mL industrial hydrochloric acid for acid dissolution, at 95°C After fully acid-dissolving, add 230mL of water and 2mL of iron-containing hydrochloric acid waste liquid with an iron content of 1% to 20%, raise the temperature to 80°C, add 5g of calcium aluminate powder, 0.05g of sodium chlorate, 0.1 g sodium sulfide, react at 98°C for 3 hours; cool, age for 24 hours, and filter to obtain reddish-brown transparent liquid product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com