Wall board structure of fixed hydraulic balance extra large storage tank

A hydraulically balanced, ultra-large technology, applied in the direction of large containers, containers, packaging, etc., can solve the problems of sealing safety, inner tank damage, complex structure, etc., to facilitate production and installation, uniform pressure transmission, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

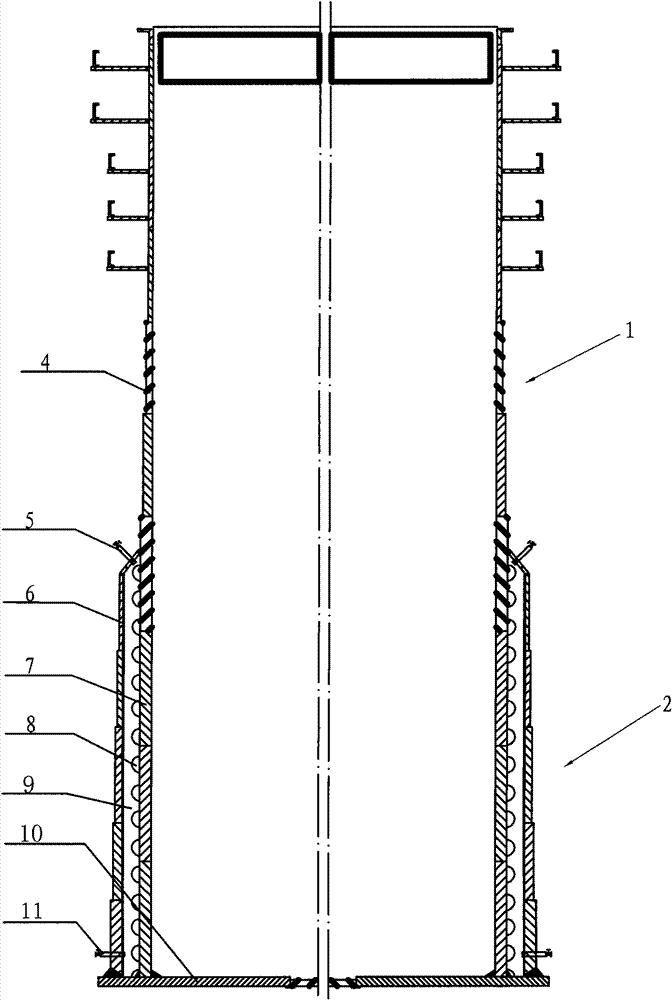

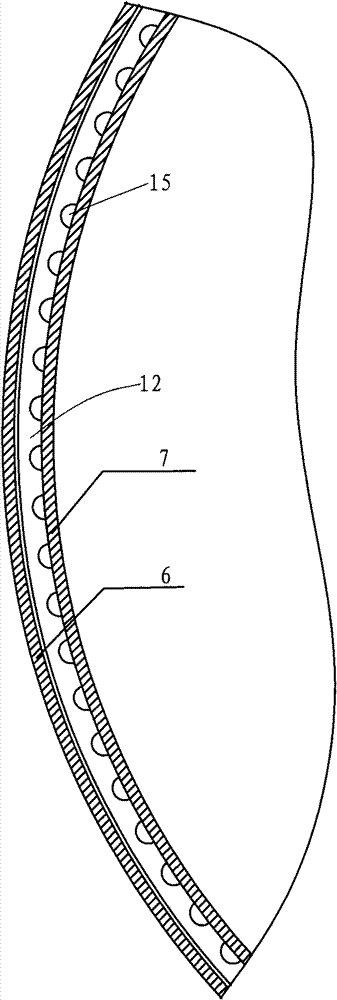

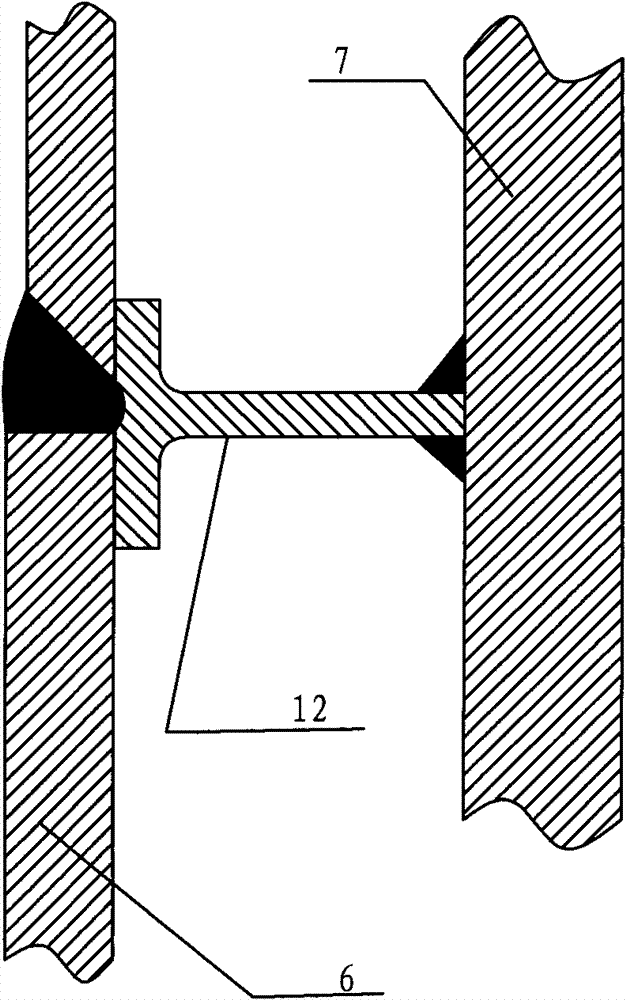

[0020] Such as Figure 1 to Figure 5 As shown, the 400,000 cubic meters double-wall fixed hydraulic balance floating roof oil tank in this embodiment is used to illustrate the structure of the storage tank.

[0021] First of all, it is necessary to calculate the materials used for the inner tank, outer tank and T-shaped steel according to the design volume of the storage tank.

[0022] The difference from the calculation method of ordinary oil tanks is that the influence of the balance side pressure should be considered when calculating the strength of the tank wall of the fixed hydraulic balance oil tank. The calculation of the strength of the inner tank wall should be divided into two parts. The part above the hydraulic balance point is the same as that of the ordinary tank wall. The part below the hydraulic balance point should consider th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com