Rope reeving structure for crane

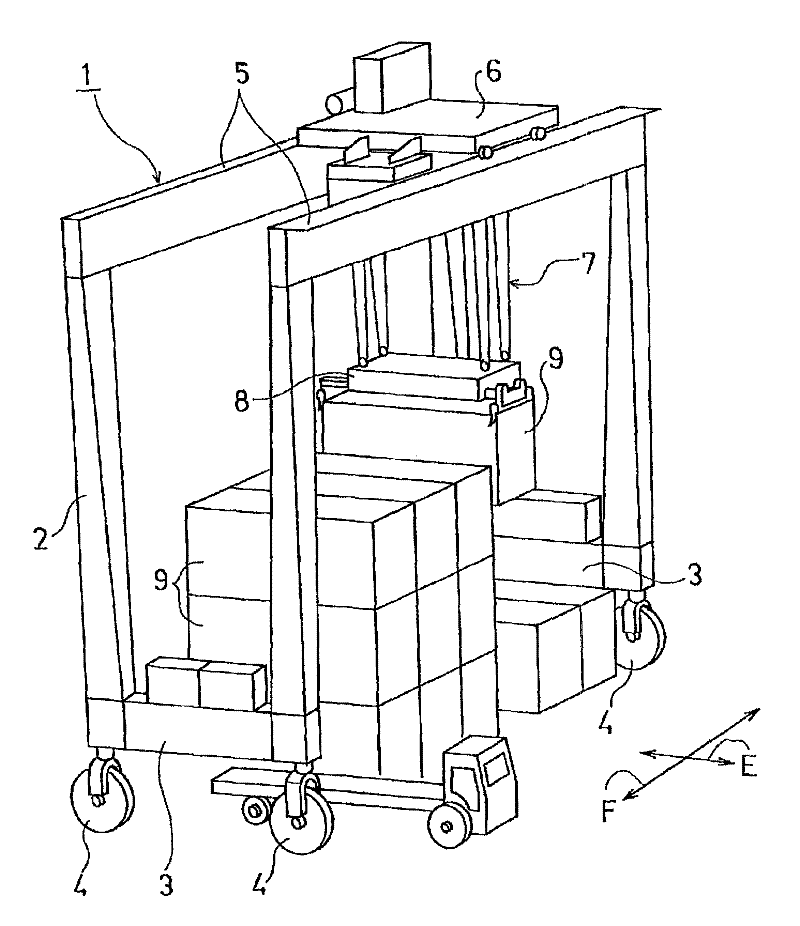

A crane and steel cable technology, which is applied to cranes, trolley cranes, load hanging components, etc., can solve the problems of increased weight, not necessarily high responsiveness, and high manufacturing costs, and achieves simple structure, low cost, high lift and high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

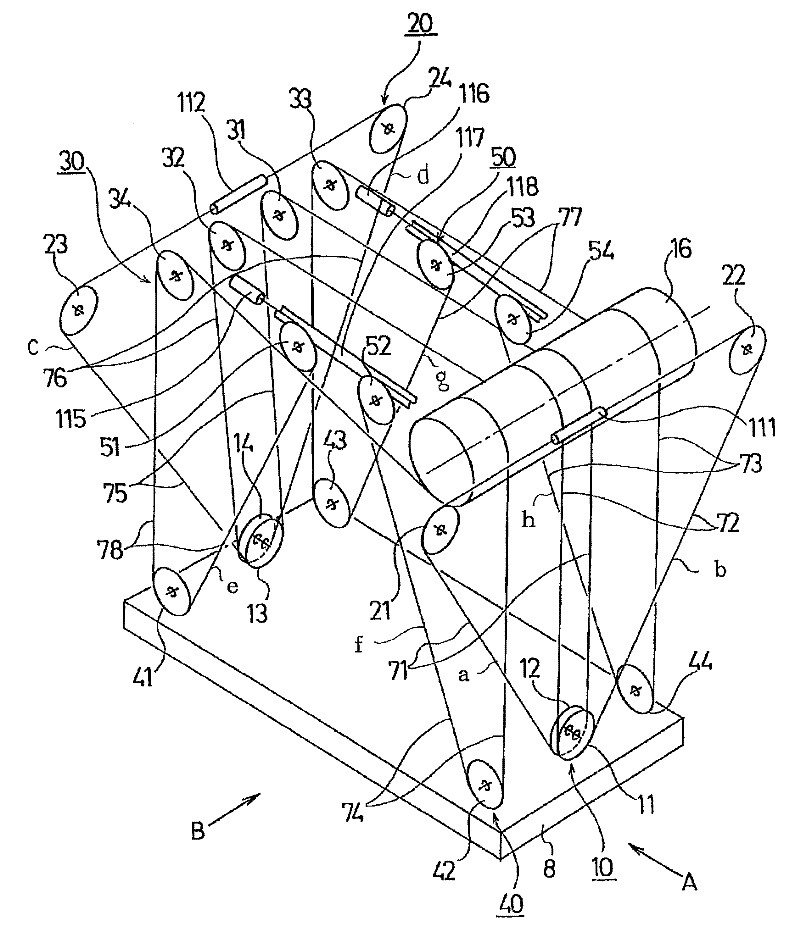

Method used

Image

Examples

Embodiment approach 2

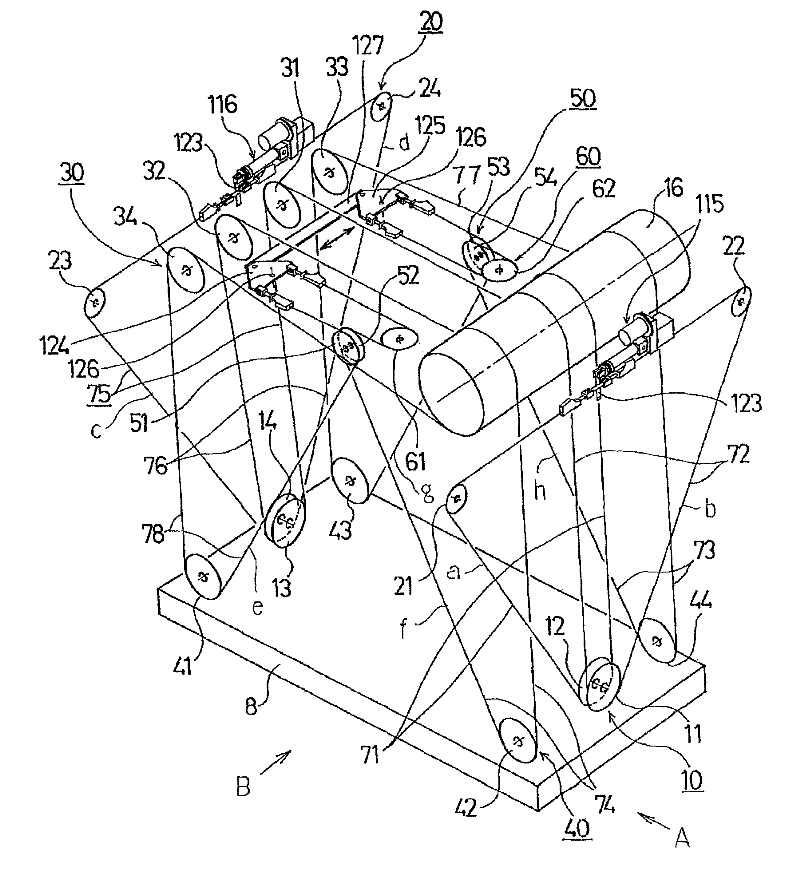

[0076] Next, the second embodiment of the present invention will be described, and the same components as those in the first embodiment will be assigned the same reference numerals and detailed description will be omitted.

[0077] The first difference is that, if Figure 8 As shown, single-head cylinder-type tilt-twist devices 115 , 116 are used instead of double-head cylinder-type tilt-twist devices 111 , 112 . In this case, the arm 123 arranged on the connecting portion of the first and second steel cables 71, 72 is operated laterally to the spreader 8 by the single-head oil cylinder type tilting and twisting device 115. The head cylinder type tilting and twisting device 116 operates the arm 123 provided on the connecting portion of the fifth and sixth wire ropes 75 and 76 in the lateral direction of the hoisting tool 8 .

[0078] The second difference is that a connecting rod 127 parallel to the horizontal direction of the spreader 8 is set on the crane trolley, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com