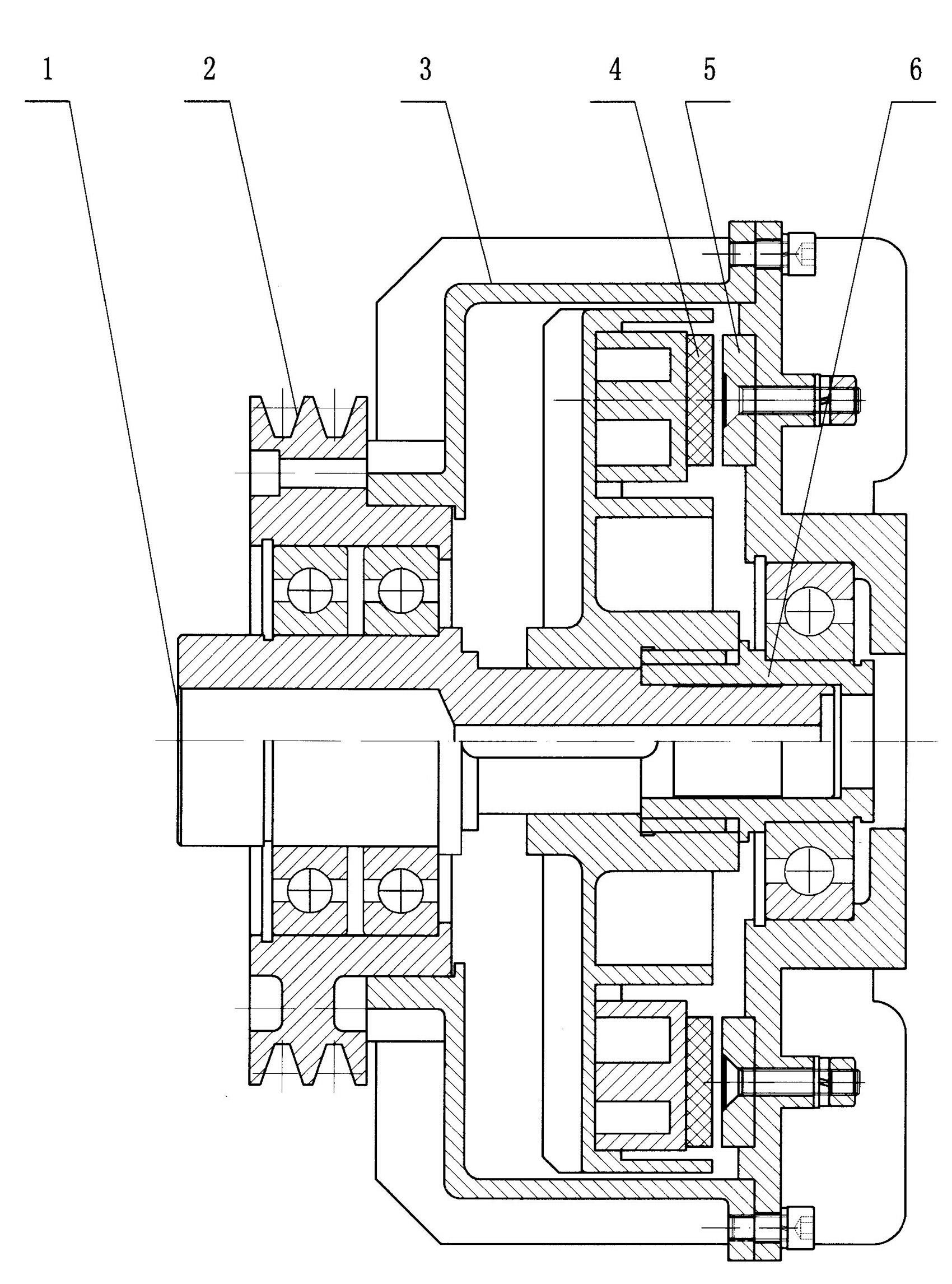

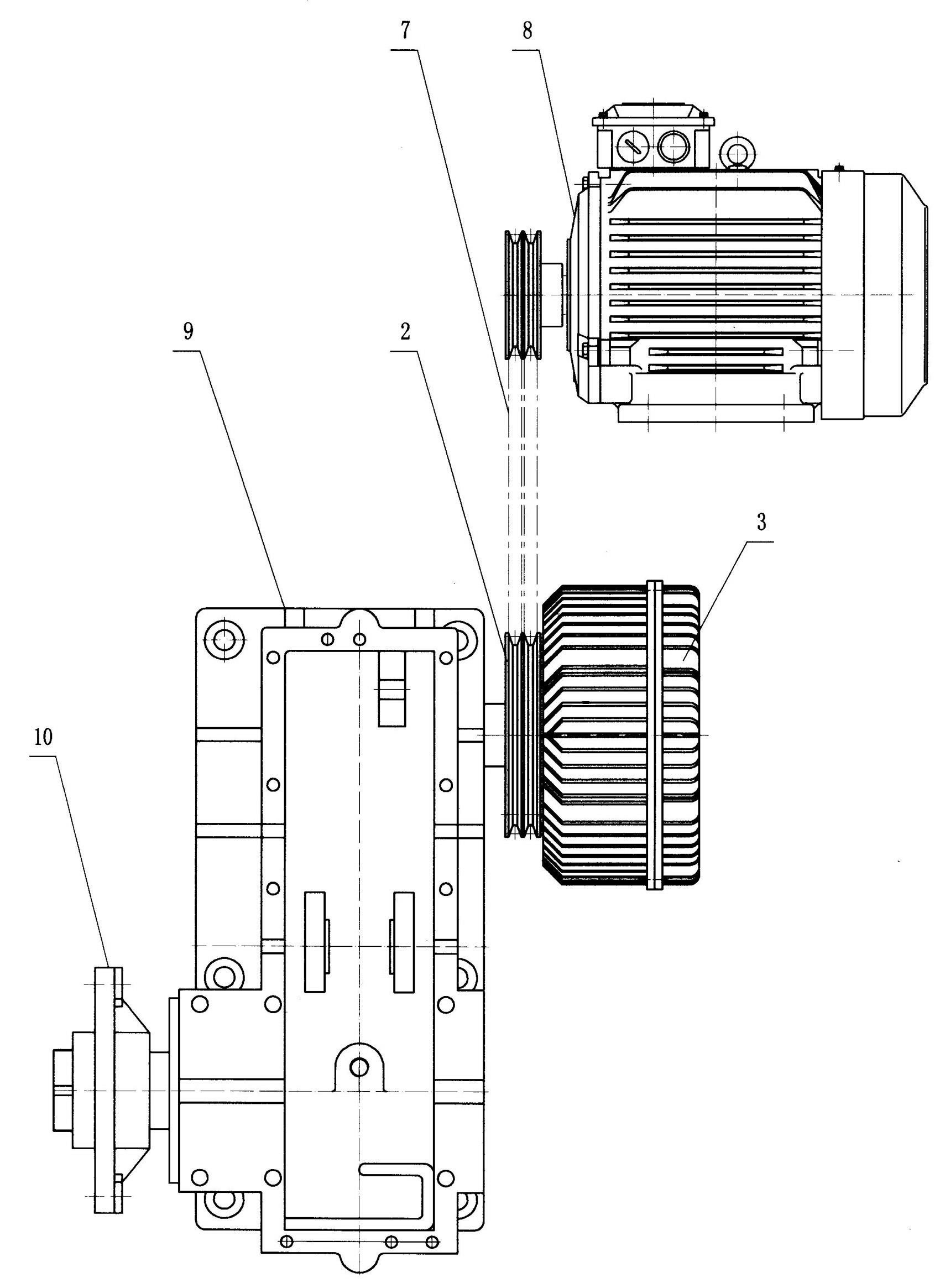

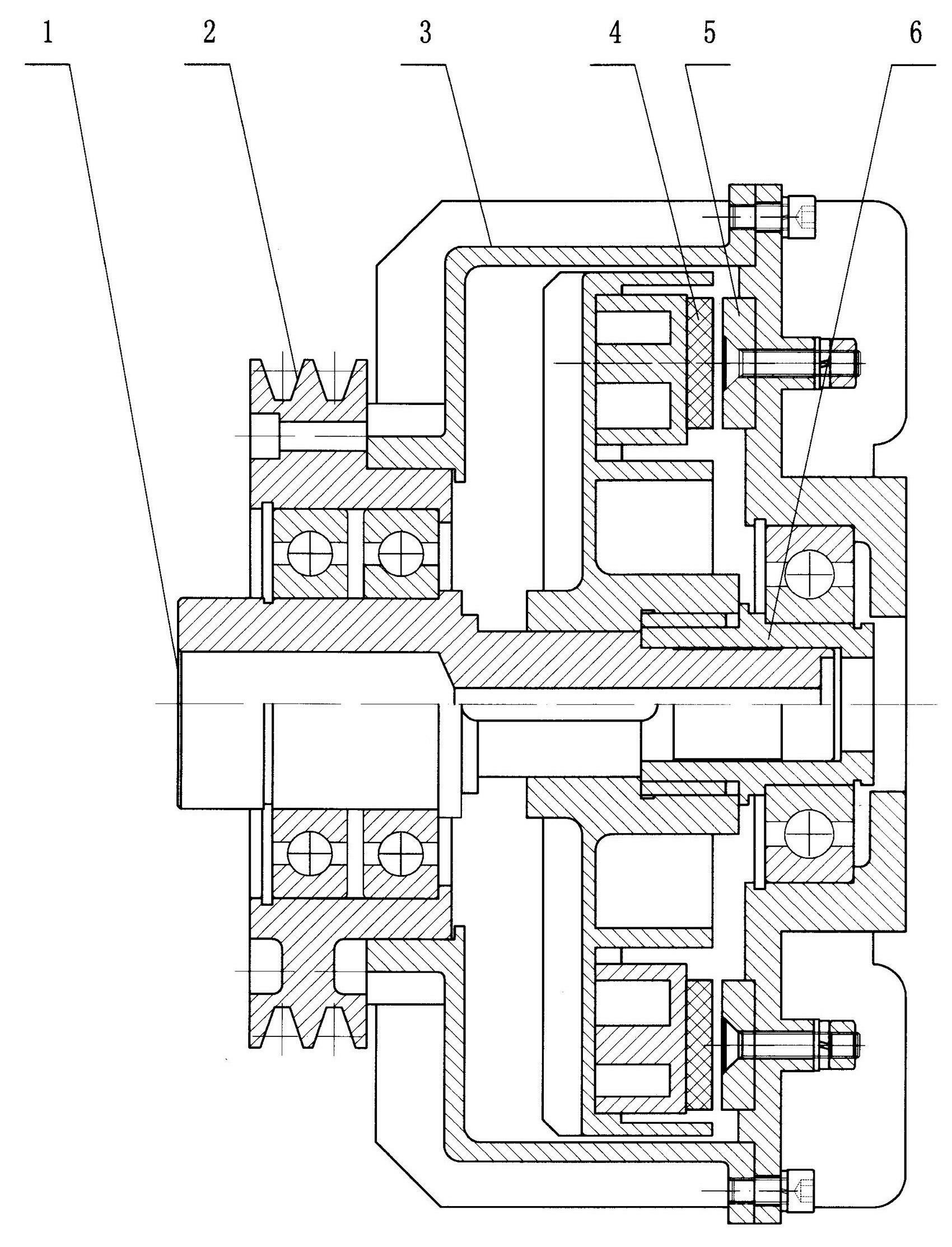

Belt type hysteresis coupler

A coupling and belt-type technology, which is applied in the field of belt-type hysteresis couplings, can solve problems such as deformation and damage of cushion pads, ineffective buffering of coupling transmission, damage to hysteresis couplings, etc., to achieve convenient torque adjustment and increase service life , Reduce the effect of equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Install a reel on the output flange. The reel is used to reel the cable. The cable is used for power supply to a mobile device, and the tension on the cable is required to be constant; If the drive motor is still running when it is blocked, it can ensure that the cable will not be damaged due to the blockage. According to the working principle and advantages of the present invention, it can be found that the requirements can be fully met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com