Large-scale steel wire release device

A pay-off device and steel wire technology, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as baffle crushing and damage to the wire pay-off device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

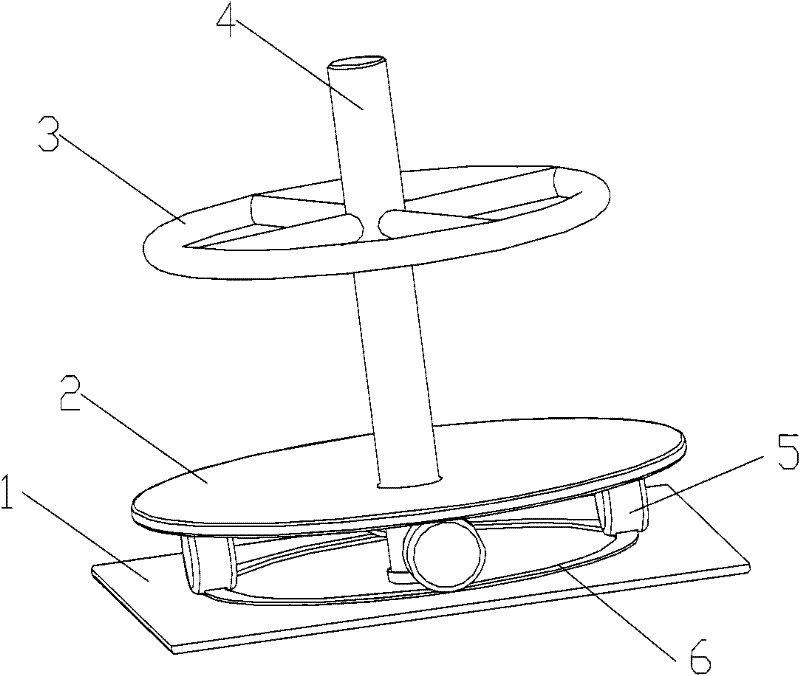

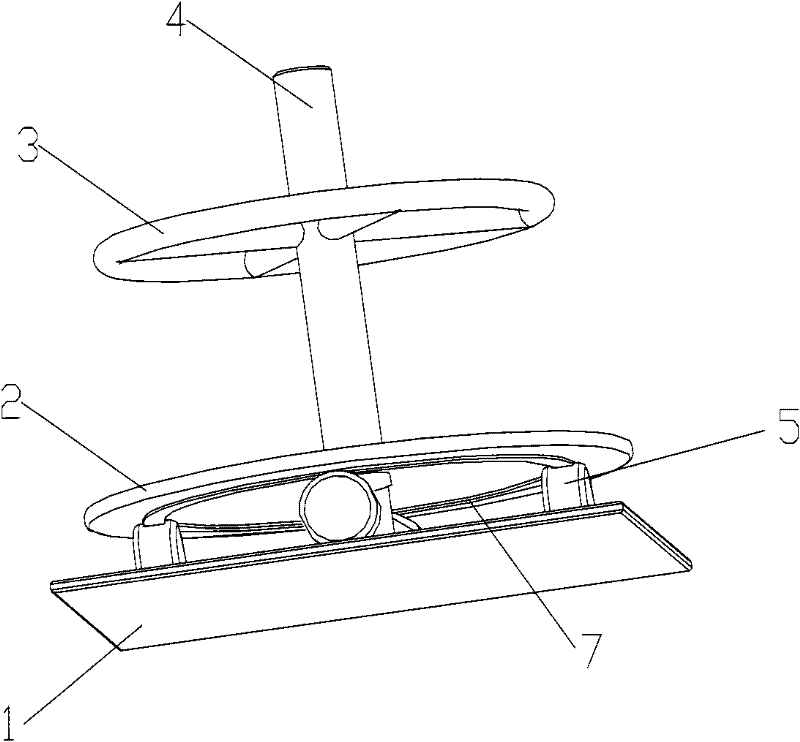

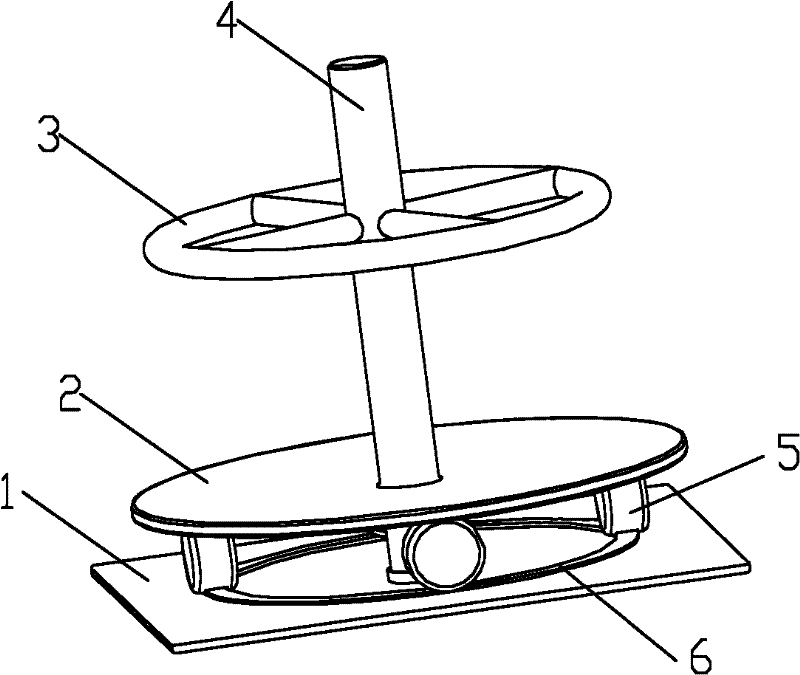

[0013] as attached figure 1 , 2 Shown is a large steel wire pay-off device of the present invention, comprising a support plate 1, a vertical shaft 4, and a roller 5, the vertical shaft 4 is vertically arranged on the support plate 1; the near upper end of the vertical shaft 4 is provided with a retaining ring 3; the near lower end of the vertical shaft 4 is provided with a support plate 2; a bearing is provided between the support plate 2 and the vertical shaft 4; the roller 5 is arranged between the support plate 1 and the support plate 2; The support plate 1 is provided with a circular first slide rail 6; the lower surface of the support plate 2 is provided with a circular second slide rail 7; the roller 5 is arranged on the first slide rail 6 and the second slide rail 7 Between; the first slide rail 6 and the second slide rail 7 are protruding outward; the roller 5 is provided with a groove; the groove is sleeved on the protrusion.

[0014] Due to the application of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com