Hot runner hot nozzle assembly capable of directly changing color

A hot runner and hot nozzle technology, applied in the field of hot runner and hot nozzle components, can solve the problems of easy retention of molten plastic, affecting production efficiency and product quality, and waste of raw materials, so as to improve production efficiency and product quality, and reduce product color impurities. , The effect of solving the problem of stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

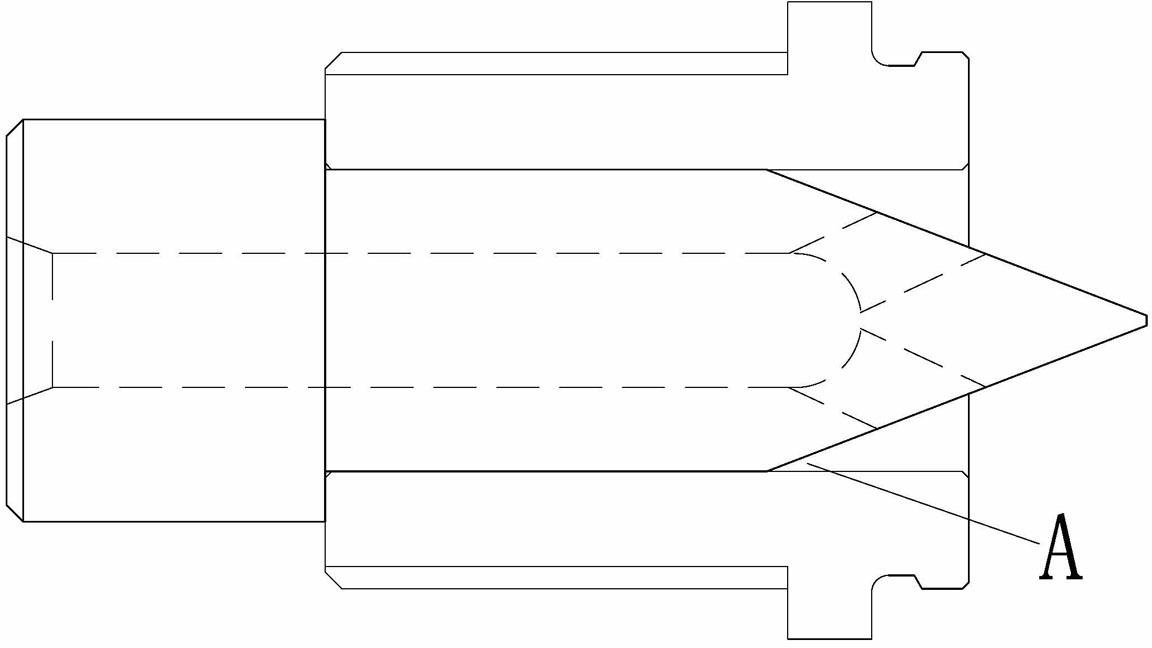

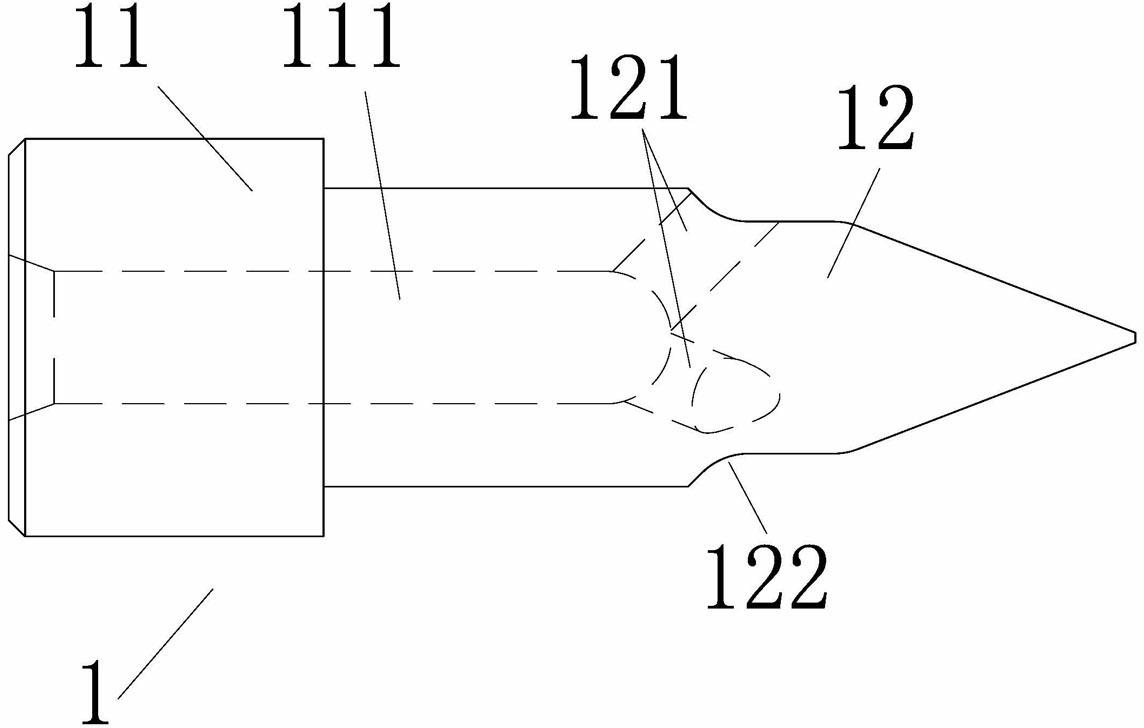

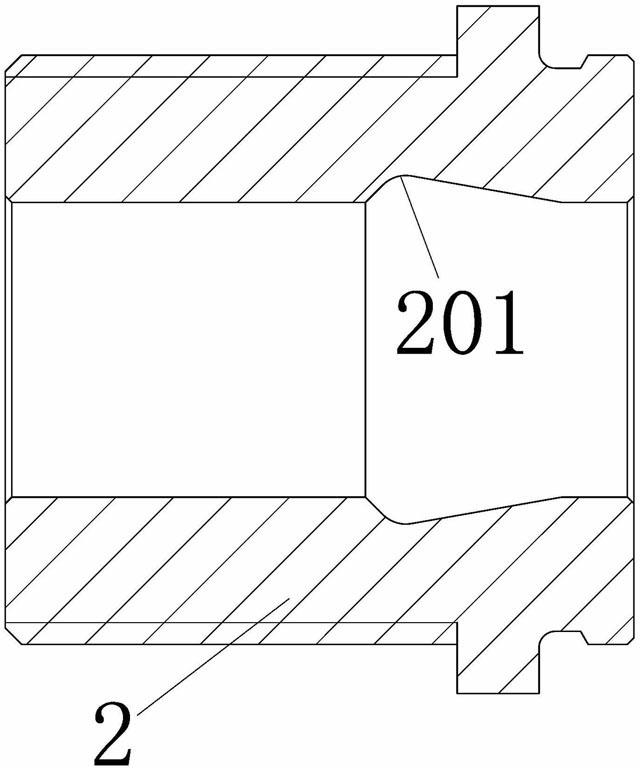

[0019] Such as Figure 2-7 As shown, the hot runner hot nozzle assembly that can directly change the color of the present invention includes a hot nozzle tip 1, 3 and a special-shaped nut 2, 4. The hot nozzle tip 1, 3 includes a body 11, 31 and a nozzle tip 12, 32. There is a flow channel 111, 311 in the body 11, 31; the tip 12, 32 is provided with a plurality of shunt passages 121, 321 communicating with the flow passage 111, 311; the outlet of the shunt passage 121, 321 is located at The tip of the tip 12, 32, the surface of the tip at the exit is a concave annular transition arc surface 122, 322; the special-shaped nut 2, 4 is set on the tip of the nozzle 1, 3, and the front end of the inner cavity is connected with the tip of the tip of the nozzle. The main bodies 11, 31 are matched, and the inner surface of the end is an inverted tapered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com