Mould heating furnace for isothermal forging

A technology of mold heating and isothermal forging, applied in forging furnaces, furnaces, furnace types, etc., can solve the problems of temperature gradient change mold influence, heating thermal sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

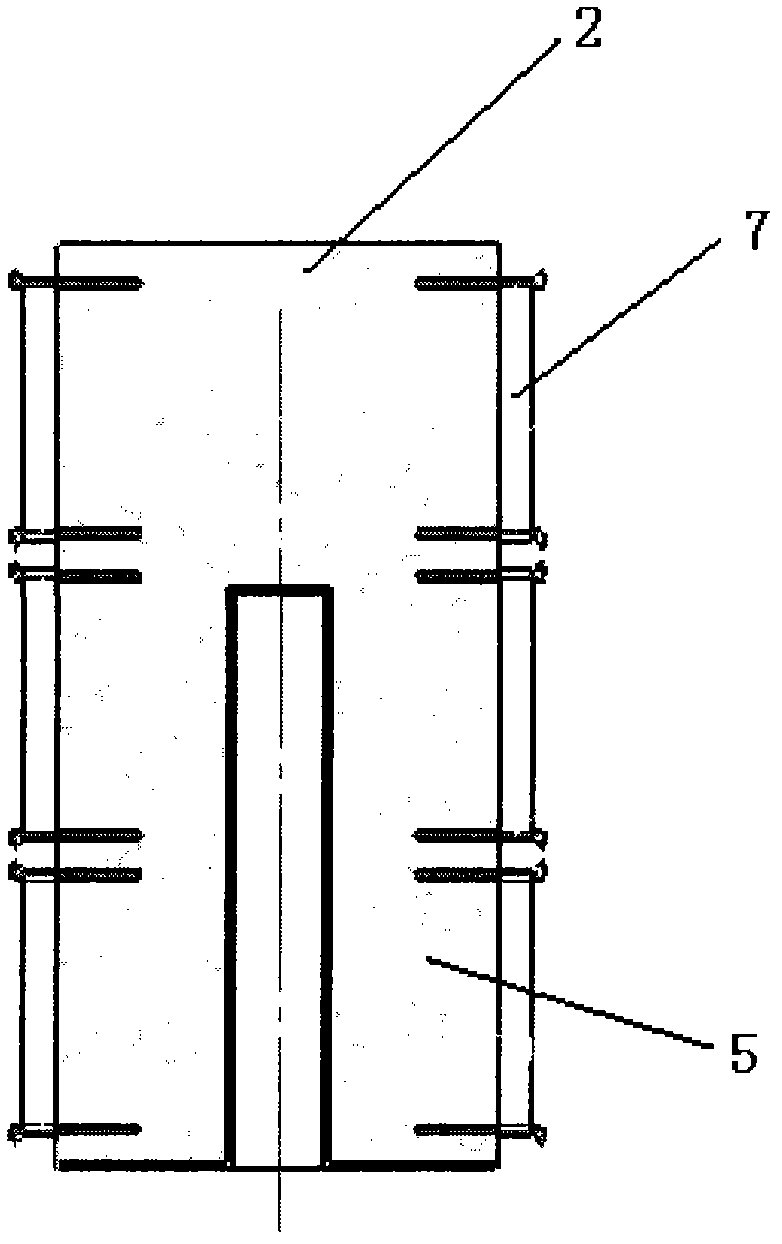

[0021] See attached figure 1 , 2 Shown, this kind of mold heating furnace for isothermal forging is characterized in that:

[0022] (1) The heating furnace mainly includes an outer furnace 1 and an inner furnace 2. The outer furnace 1 is a large annular structure. The surrounding structure of the circular inner cavity is divided into a furnace shell 3, an insulation layer 4 and a refractory layer 5, and the outer furnace 1 is divided into two parts with the same upper and lower heights, namely the upper outer furnace body 11 and the lower outer furnace body 12;

[0023] The inner furnace 2 is a cylindrical body composed of a refractory layer 5, which is set in the center of the inner cavity of the outer furnace 1. The outer circle size of the cylindrical body is based on the outer circle of the inner furnace 2 cylindrical b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface load | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Surface load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com