Permanent magnet type rotating electric machine

A technology of permanent magnets and rotating motors, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve problems such as deterioration of comprehensive operating efficiency, and achieve the effect of realizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] (1. The first embodiment)

[0054] (1-1. Composition)

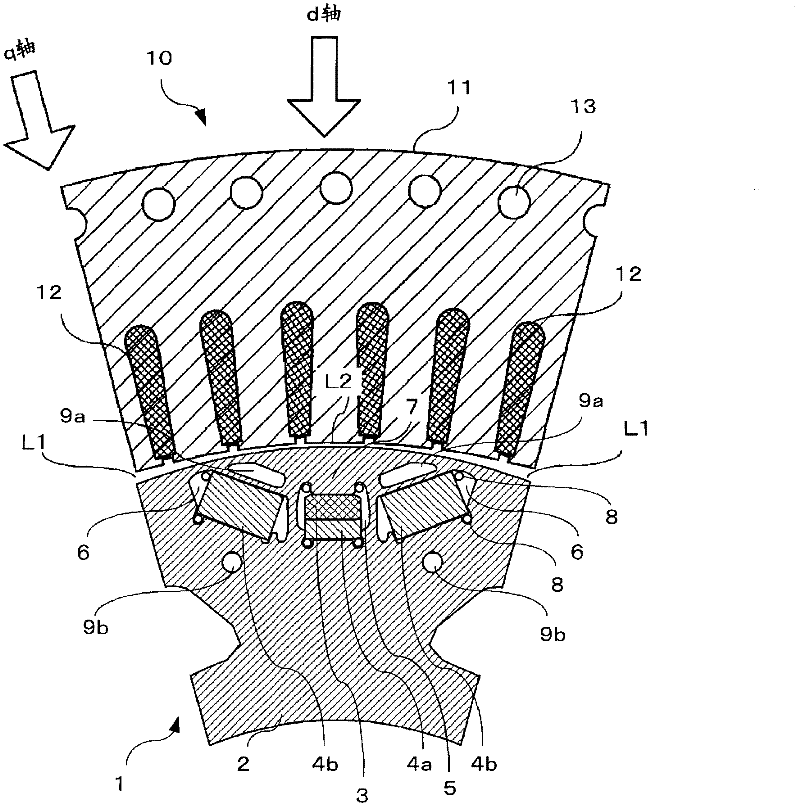

[0055] use figure 1 The first embodiment of the present invention will be described.

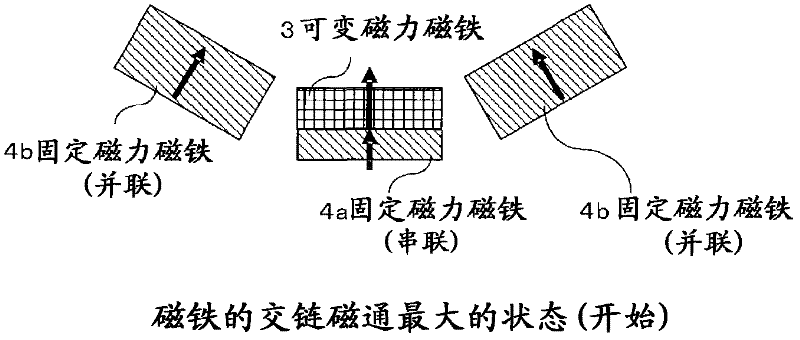

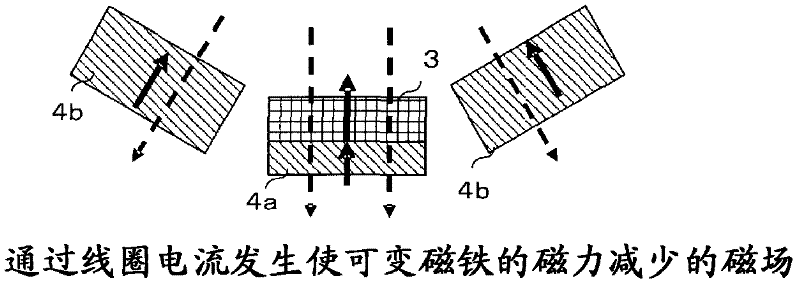

[0056] The rotor 1 of the first embodiment of the present invention consists of figure 1 As shown, the rotor core 2, the permanent magnet 3 having a small product of the coercive force and the thickness in the magnetization direction (hereinafter, referred to as a variable magnetic force magnet), and the permanent magnet having a large product of the coercive force and the thickness of the magnetization direction (hereinafter, Be called fixed magnetic force magnet) 4a, 4b constitute. Here, 4a indicates one fixed magnetic force magnet arranged in series with the variable magnetic force magnet 3 on the magnetic circuit, and 4b indicates two fixed magnetic force magnets arranged in parallel with the variable magnetic force magnet 3 on the magnetic circuit. The rotor core 2 is formed by laminating silicon steel plates, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com