Rice protein polypeptide and preparation method thereof

A technology of rice protein and protein, applied in the field of rice protein polypeptide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

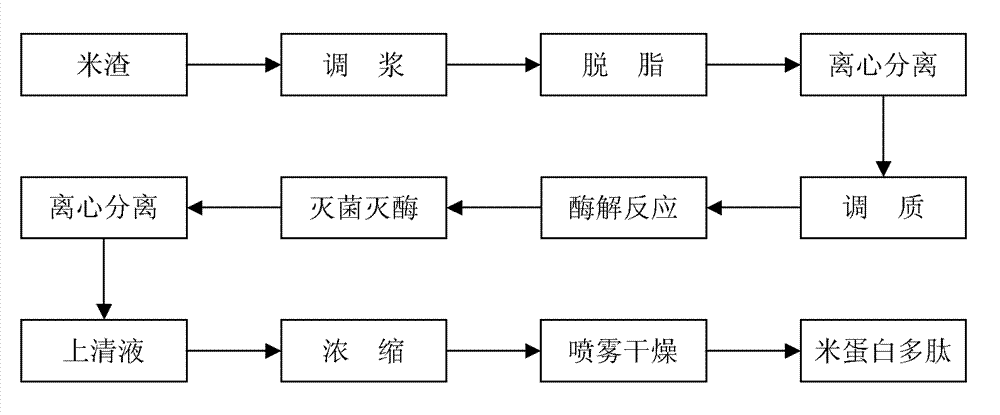

[0093] Embodiment 1: The compound enzyme method of the present invention prepares rice protein polypeptide method

[0094] The steps of this method are as follows:

[0095] (1) Mixing

[0096] The rice dregs sold by Yunnan Pu'er Yongji Biotechnology Co., Ltd. were screened in advance with a 150-mesh sieve to obtain rice dregs with a particle size of 150 mesh. Then weigh 2kg protein weight percentage 90% and fat weight percentage 3% rice dregs, according to rice dregs and water weight ratio 1: 7, rice dregs and 14kg water are stirred and mixed to obtain a kind of feed liquid, and then Heating was carried out at a temperature of 70°C.

[0097] (2) Degreasing

[0098] with saturated Ca(OH) 2 Aqueous solution Adjust the pH value of the feed liquid obtained in step (1) to 9.5, stir evenly, and then soak and degrease at a temperature of 75° C. for 30 minutes.

[0099] (3) centrifugal

[0100] Using the centrifuge produced by Xiangtan Centrifuge Co., Ltd., the feed liquid obtai...

Embodiment 2

[0118] Embodiment 2: the method for preparing rice protein polypeptide by compound enzyme method of the present invention

[0119] (1) Mixing

[0120] The rice dregs sold by Yunnan Pu'er Yongji Biotechnology Co., Ltd. were screened in advance with a 100-mesh sieve to obtain rice dregs with a particle size of 100 mesh. Then weigh 2kg protein weight percentage 80% and fat weight percentage 4% rice dregs, according to rice dregs and water weight ratio 2: 9, rice dregs and 9kg water are stirred and mixed to obtain a kind of feed liquid, and then Heating was carried out at a temperature of 75°C.

[0121] (2) Degreasing

[0122] with saturated Ca(OH) 2 Aqueous solution Adjust the pH value of the feed solution obtained in step (1) to 9.7, stir evenly, and soak and degrease at a temperature of 73° C. for 20 minutes.

[0123] (3) centrifugal

[0124] Using the centrifuge produced by Xiangtan Centrifuge Co., Ltd., the feed liquid obtained in step (2) was centrifuged at a speed of 3...

Embodiment 3

[0135] Embodiment 3: the method for preparing rice protein polypeptide by compound enzyme method of the present invention

[0136] The steps of this method are as follows:

[0137] (1) Mixing

[0138] Use a 200-mesh sieve to screen the rice dregs sold by Yunnan Pu'er Yongji Biotechnology Co., Ltd. in advance to obtain rice dregs with a particle size of 200 mesh. Then weigh 2kg protein weight percentage 70% and fat weight percentage 2% rice dregs, according to rice dregs and water weight ratio 3: 8, rice dregs and 5.3kg water are stirred and mixed to obtain a kind of feed liquid, and then Heating was carried out at a temperature of 73°C.

[0139] (2) Degreasing

[0140] with saturated Ca(OH) 2 Aqueous solution Adjust the pH value of the feed solution obtained in step (1) to 10.0, stir evenly, and soak and degrease at a temperature of 70° C. for 40 minutes.

[0141] (3) centrifugal

[0142] Using the centrifuge produced by Xiangtan Centrifuge Co., Ltd., the feed liquid obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com