A rear wheel suspension with coil springs with inclined lines of force

A line of action and suspension technology, applied in the direction of elastic suspension, suspension, vehicle spring, etc., can solve the problems of easy to hear, etc., and achieve the effect of reducing weight, increasing movement, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

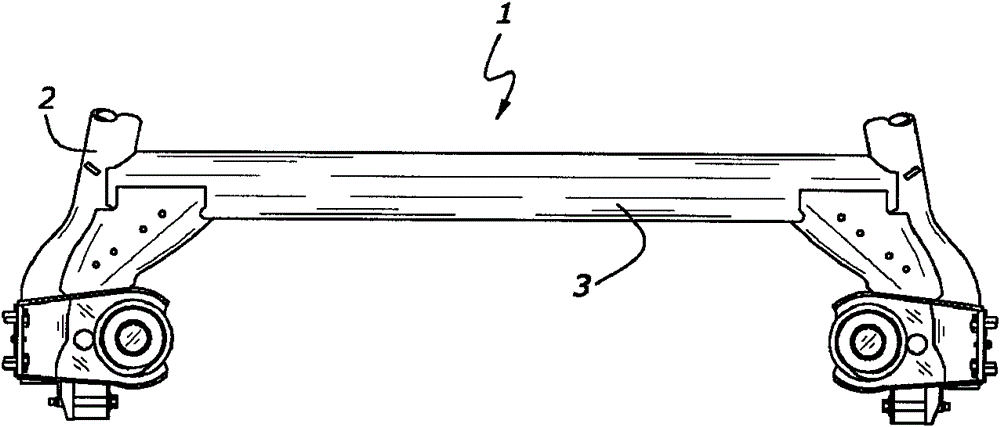

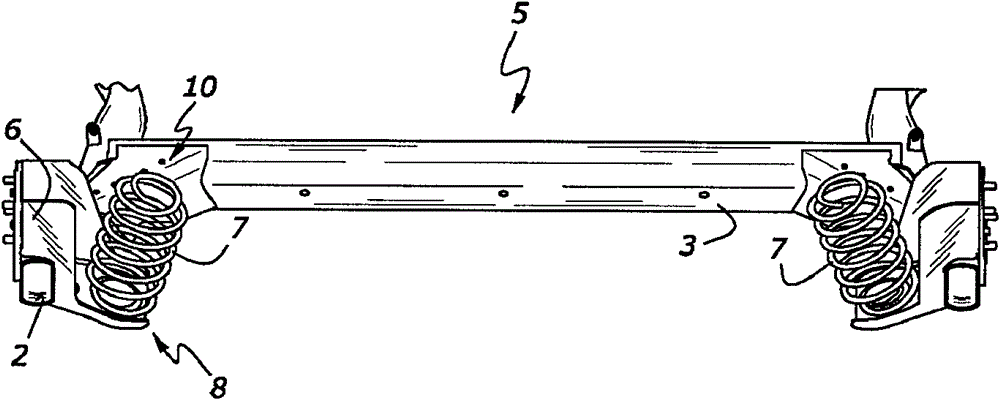

[0027] In the different figures, the same parts always have the same references, and for this reason the above-mentioned parts are generally only described once.

[0028] figure 2 Indicates as according to the known technology figure 1 The shown rear wheel suspension 5 is embodied by way of example as a semi-independent axle 5 . The semi-independent axle 5 has a longitudinal pivot arm 2 assigned to each hub carrier 6 . The longitudinal pivot arms 2 are connected to one another via a section 3 . The longitudinal pivoting arms 2 and the profiles 3 or structural elements of the rear wheel suspension 5 can have many different designs, but no further details will be given here.

[0029] Bearing bushings are likewise arranged on the longitudinal pivot arm 2 , but are not shown.

[0030] Each longitudinal oscillating arm 2 is assigned a spring 7, which in a preferred embodiment is a helical spring 7, which bears on the respective longitudinal oscillating arm 2 at one end, i.e. t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com