Antifoaming device used for biological fermentation

A defoaming device and bio-fermentation technology, applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactor/fermentation tank combinations, etc., can solve cleaning and sterilization dead ends, bacterial contamination, and loss of fermentation broth and other problems, to achieve the effect of simple structure, easy cleaning, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

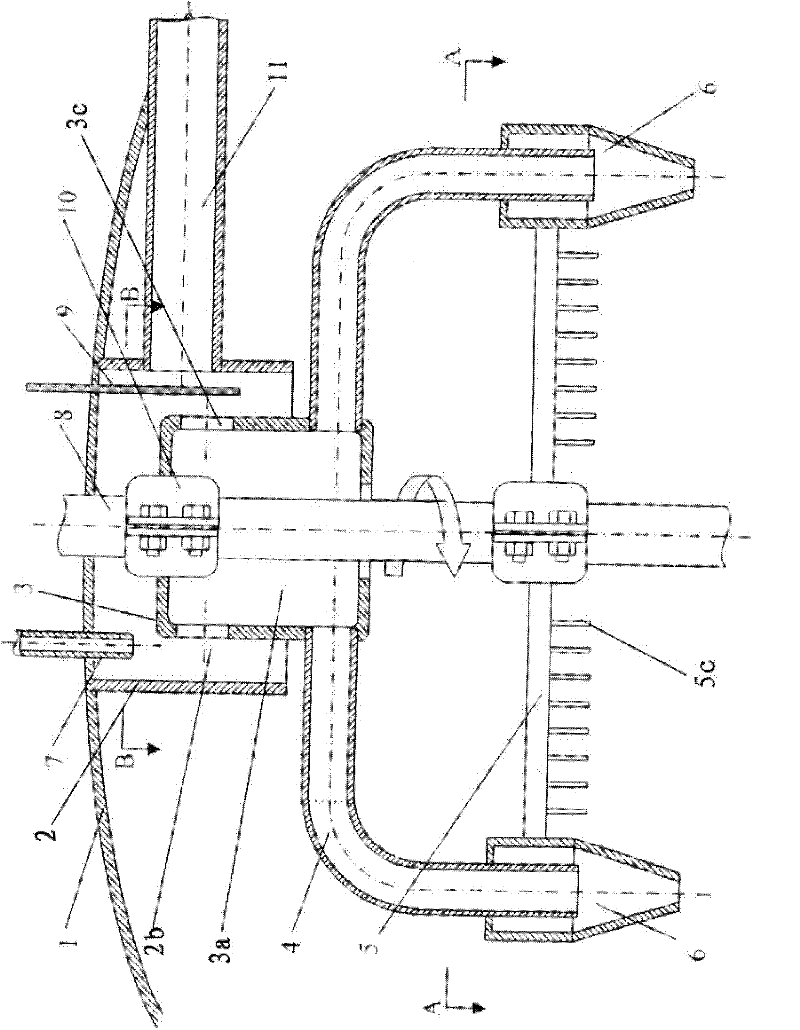

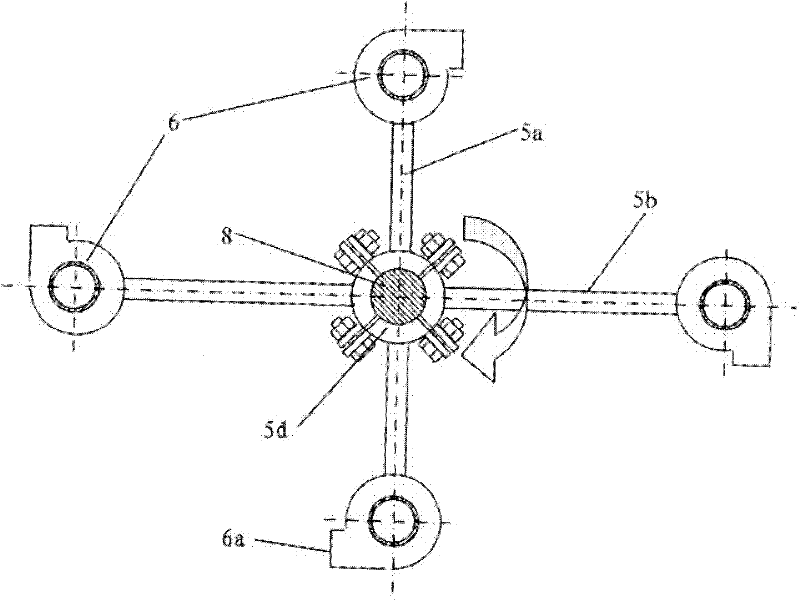

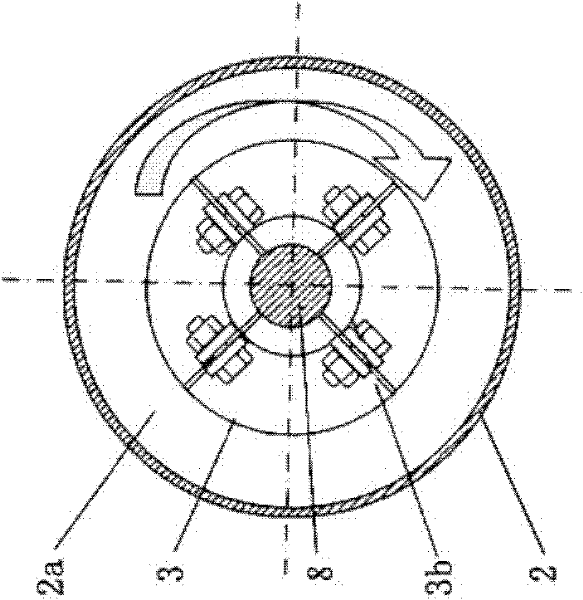

[0015] refer to Figure 1 to Figure 3 , the bio-fermentation defoaming device of the present invention mainly consists of a fermenter 1, a stirring shaft 8, a static cylinder 2, a rotating device 3, a gas-liquid separation device, and a foam breaking device. The following is for each part and between each part The structure is described in detail (the fermenter and the stirring shaft are existing components, so they will not be described in detail):

[0016] A static cylinder 2 with a static cavity 2a is fixed on the inner top wall of the fermenter 1 by welding, and the lower end of the stirring shaft 8 passes through the static cavity 2a of the static cylinder 2 . A hole is arranged on the side wall of the static cylinder 2, and one end of the exhaust pipe 11 is inserted into the hole to communicate with the static cavity 2a of the static cylinder, and the other end of the exhaust pipe 11 passes through the side wall of the fermenter. The static cylinder is stationary during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com