Crossed cylindrical roller guide rail for instrument lathe

A cylindrical roller and instrument lathe technology, applied in the field of machine tools, can solve the problems of poor follow-up performance, difficult to guarantee the working accuracy of machine tools, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

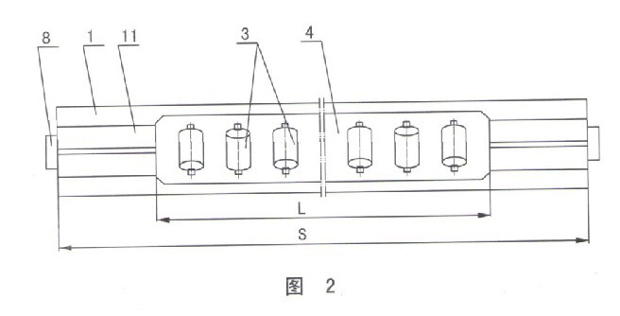

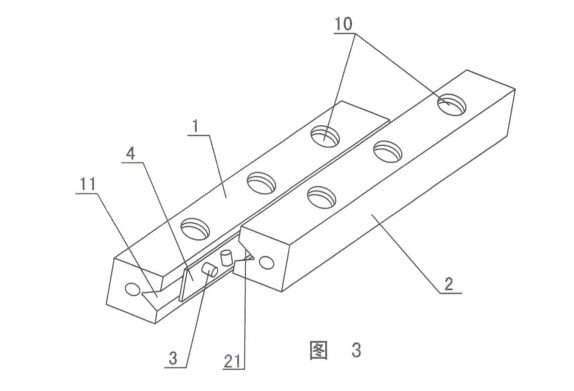

[0011] The invention relates to a crossed cylindrical roller guide rail of an instrument lathe, such as figure 1 — Figure 4 As shown, it includes a lathe bed, a cross carriage and an upper carriage, and is characterized in that a cylindrical roller guide rail pair is installed between the lathe bed and the cross carriage and between the cross carriage and the upper carriage, and the cylindrical roller The sub guide rail pair includes two guide rails 1 and 2 with V-shaped raceways 11 and 21. Cylindrical rollers 3 are installed in the V-shaped raceways 11 and 21. The cylindrical rollers 3 have cages 4, and the adjacent ones have cages The cylindrical rollers 3 of the frame are arranged in a 90° cross arrangement with each other in the V-shaped raceways 11 and 21 . The most substantive technology of this program is to install the cylindrical rollers 3 in the two guide rails 1, 2 of the V-shaped raceways 11, 21, especially the adjacent cylindrical rollers 3 in the V-shaped racew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com