Accumulator plate pack welding table

A battery and extremely group technology, applied in the field of lead-acid batteries, can solve problems such as high labor intensity, low production capacity, and many labor procedures for workers, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

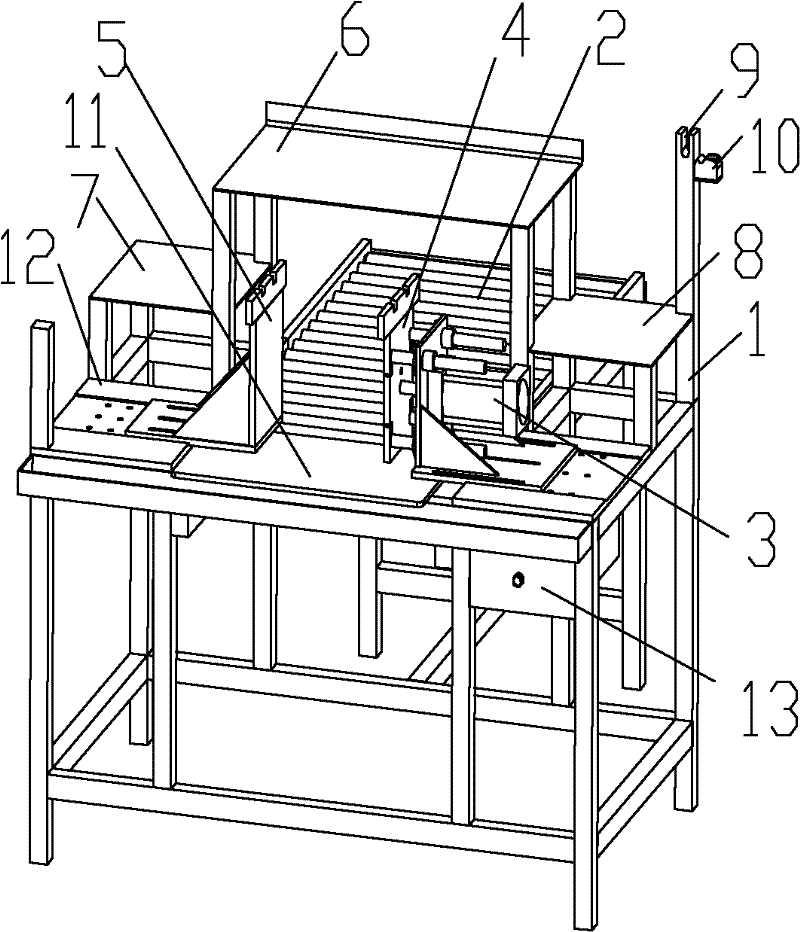

[0014] Such as figure 1 As shown, it is a schematic structural diagram of a battery electrode group welding station according to an embodiment of the present invention. Installed on the rack platform 1, the rack platform 1 is also provided with a raceway 2 for transporting batteries.

[0015] The welding station also includes a clamping device. The clamping device includes a baffle 5, a cylinder 3 fixed on the frame platform 1, and a splint 4 mechanically connected to the power output end of the cylinder 3. The baffle 5 and the splint 4 are respectively located on the rollers. The two sides of the road 2 and the positions correspond to each other. The clamping device of this embodiment can use the cylinder 3 to drive the clamping plate 4 to move towards the direction close to the baffle plate 5, so as to sandwich the battery ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com