Combined cycle and combined heat and power (CHP) equipment and process

A technology of cogeneration and combined cycle, which is applied in mechanical equipment, combined combustion mitigation, steam generation method using heat carrier, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

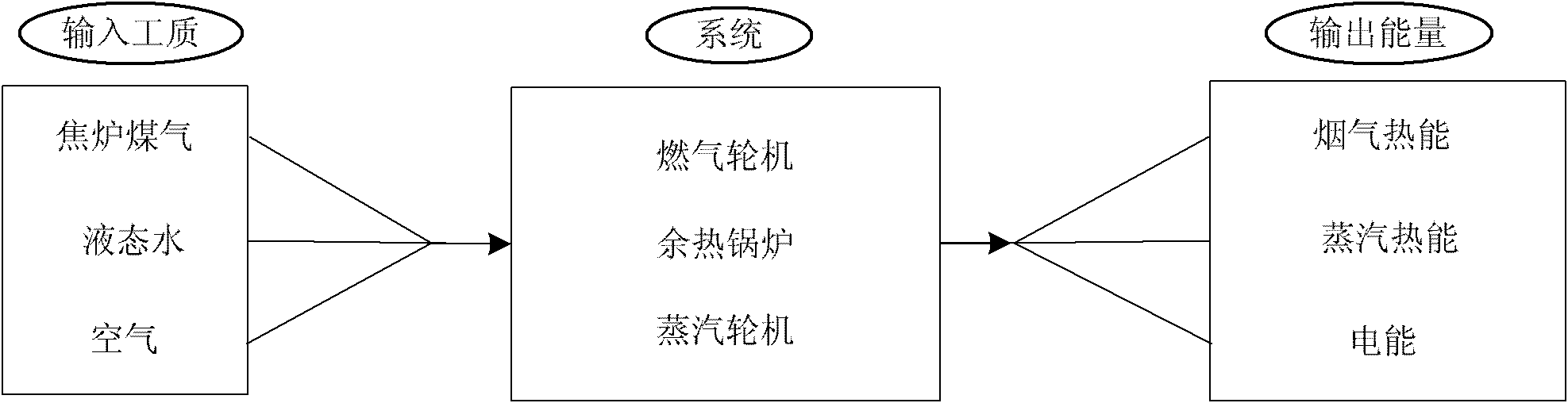

[0017] In view of the actual national conditions in which coal is the main energy source in my country, considering the large output and easy access of coke oven gas, a product of the relevant coal chemical industry, combined with thermodynamics, heat transfer, chemical kinetics, and fluid science Theory and technology, the present inventor adopts the thermodynamic cycle mode combining combined cycle and cogeneration technology, and proposes the combined cycle cogeneration process and equipment of the present invention.

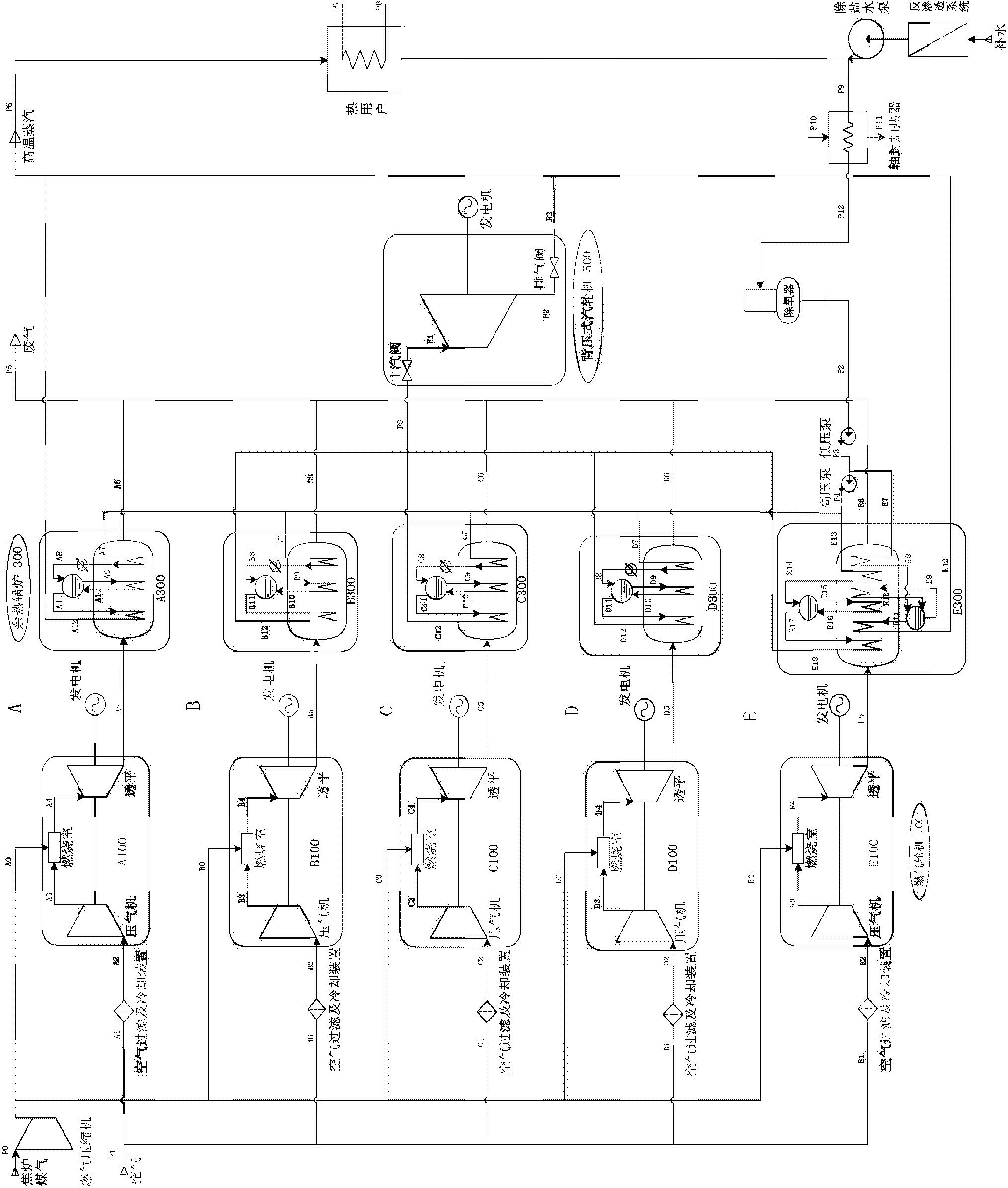

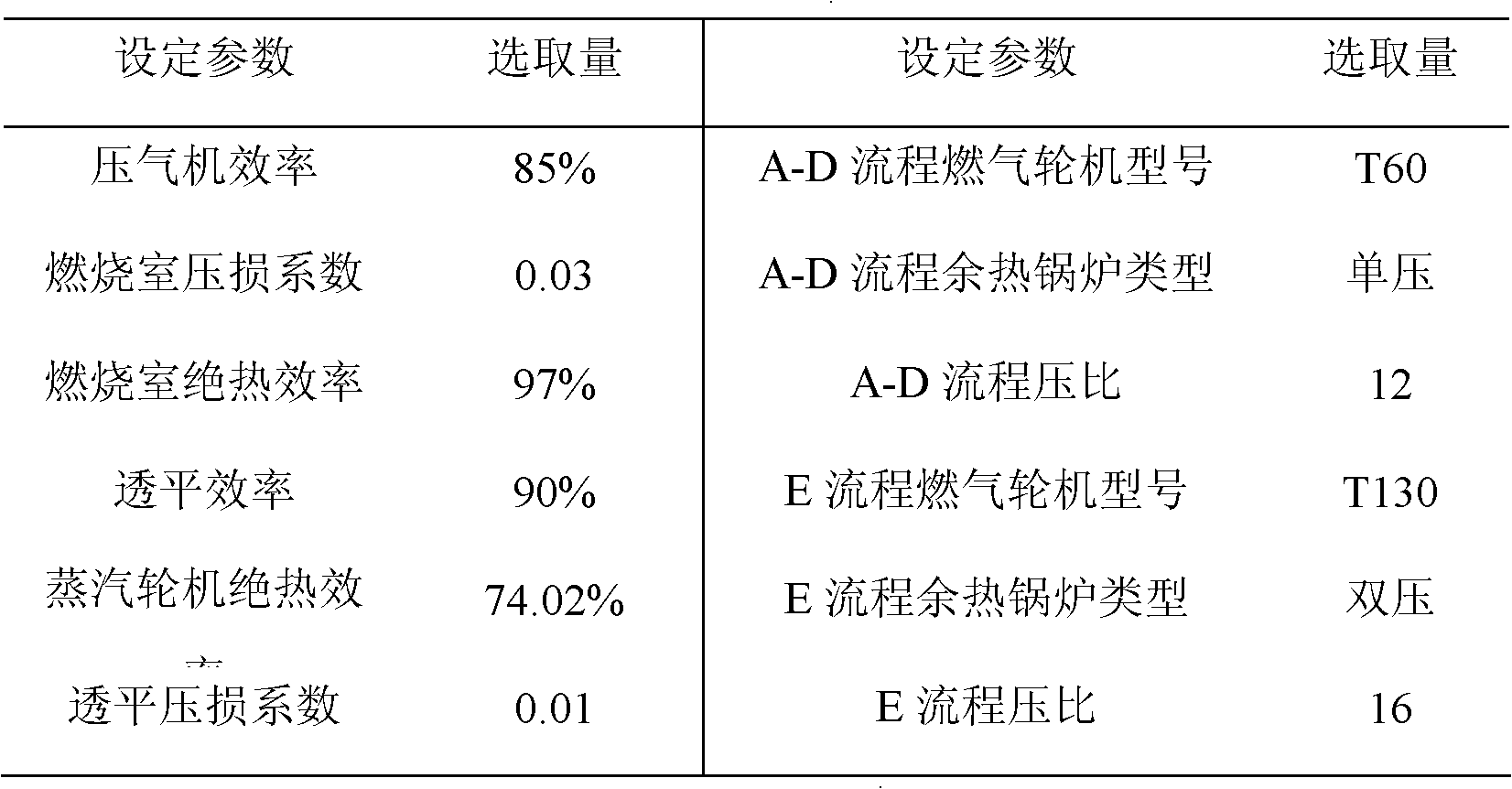

[0018] The combined cycle heat and power cogeneration process of the present invention includes a plurality of branch processes using gas turbines and waste heat boilers, and the waste heat boilers use the high-temperature flue gas discharged from the corresponding gas turbines as a heat source for heat exchange to provide steam turbines and heat users. , wherein at least one of the branch processes is an adjustable branch process to adjust and distribute the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com