Trans-lysine fermentation preparation

A technology of lysine and fermentation method, applied in the directions of fermentation, botanical equipment and methods, microorganism-based methods, etc., can solve the problems such as no reports of enzyme variants, and achieve no safety hazard, improved fermentation yield, and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

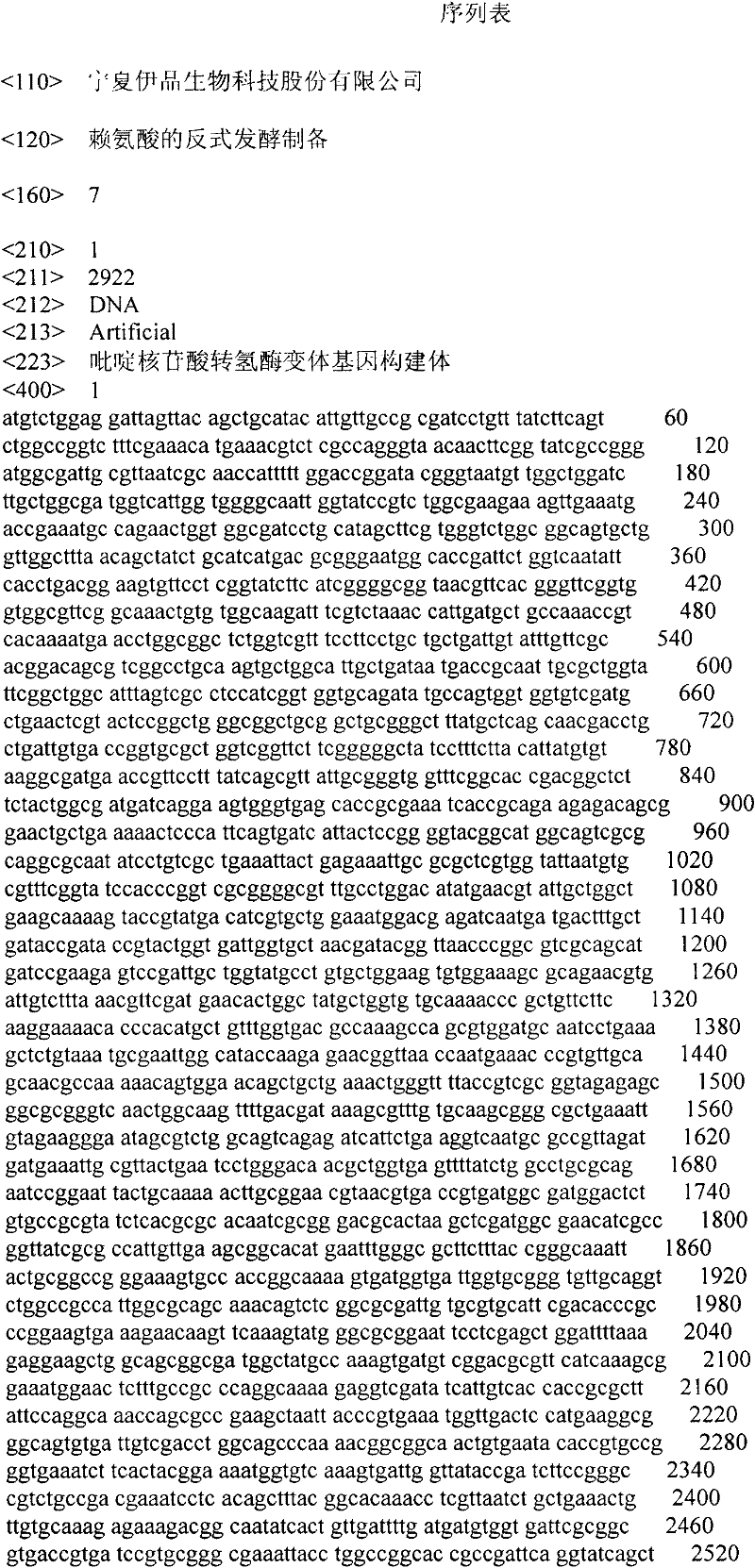

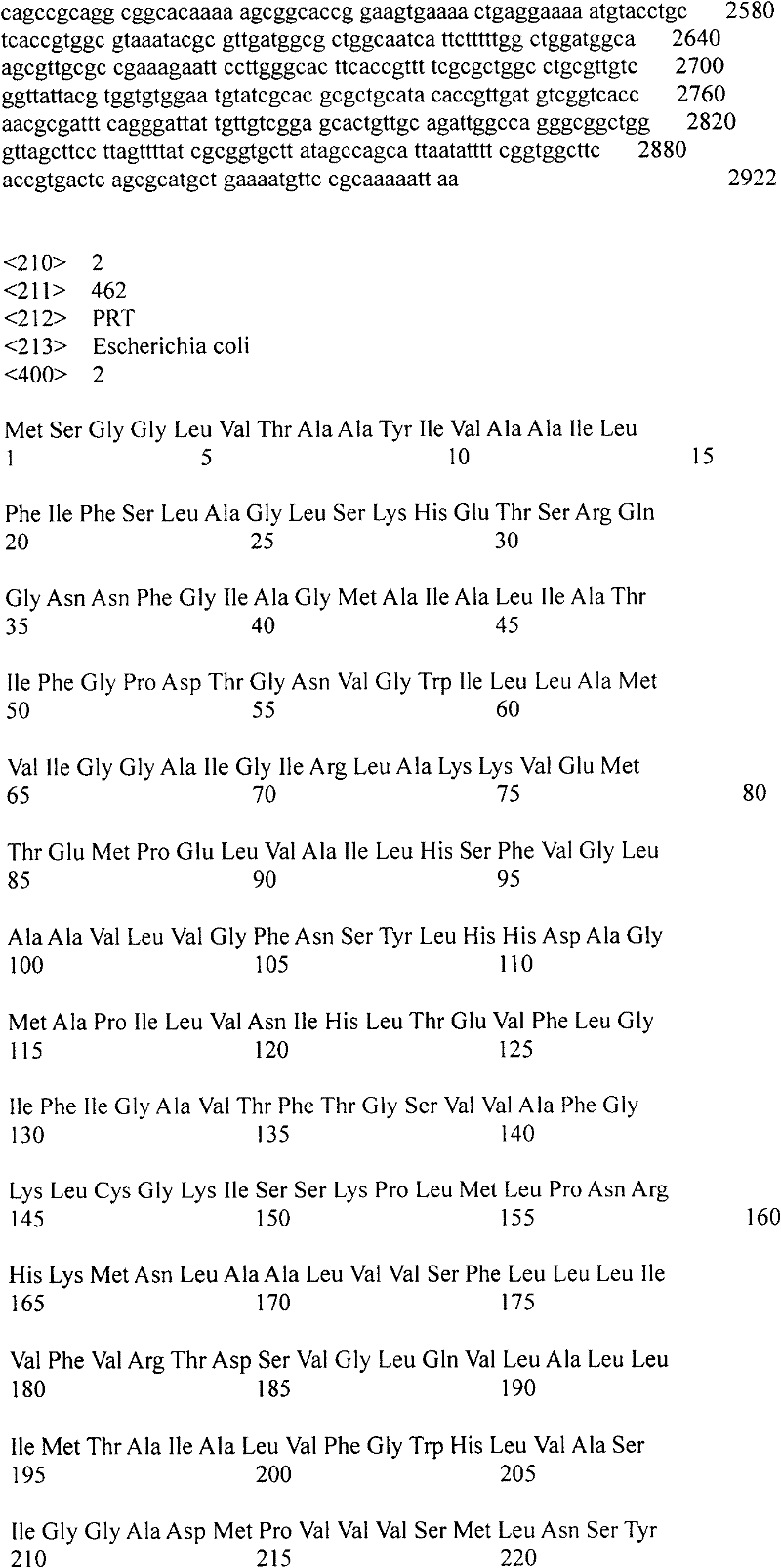

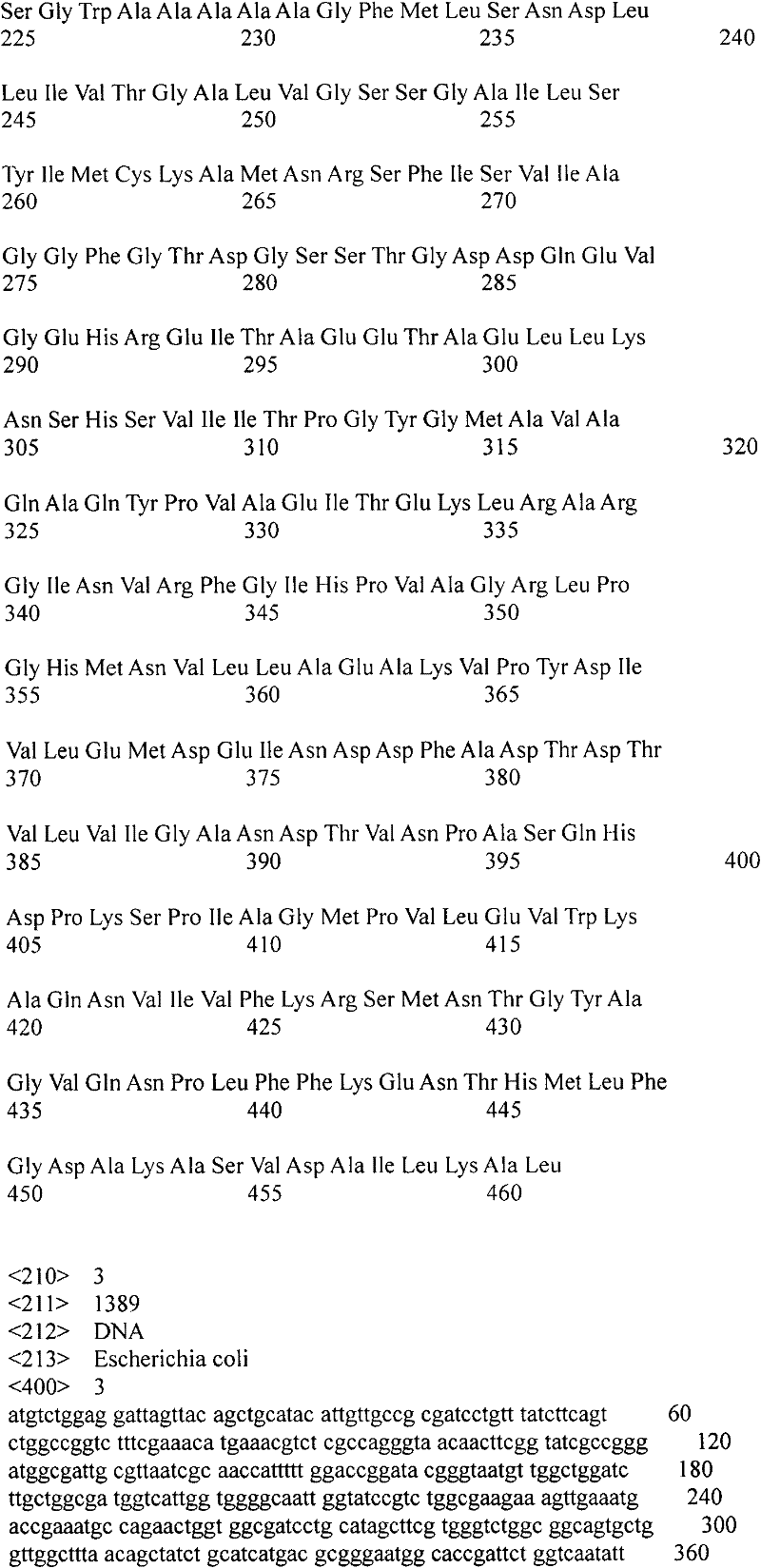

Image

Examples

Embodiment 2

[0041] The activity assay of embodiment 2 escherichia coli and the fermentation experiment of coryneform bacterium

[0042] According to the existing assay method for transhydrogenase activity (see Clarke DM et al. Cloning and expression of the transhydrogenase gene of Escherichia coli.J.Bacteriol., 162:367-373), E.coli transformed with pMS2-cispnt plasmid -tanspnt bacterial strain and the negative Top10F' bacterial strain as a control measure the transhydrogenase activity respectively, and the specific enzyme activity of the found E.coli-tanspnt bacterial strain is 138% higher than that of the negative Top10F' bacterial strain, much higher than the prior art Enzyme specific activity increase rate with wild-type pyridine nucleotide transhydrogenase expressed in .

[0043] The pMS2-tanspnt plasmid is transferred to L-lysine-fermenting coryneform bacteria engineering bacteria (available from the American Type Microorganism Collection (ATCC), product number ATCC 31269) by electro...

Embodiment 3

[0045] The preparation of embodiment 3L-lysine feed additive

[0046] The fermentation broth prepared in Example 2 was separated by a Suntar-III ultrafiltration membrane (available from Suntar Membrane Technology Co., Ltd.). Then, spray the filtrate directly into the fluidized bed dryer in the form of mist and keep the tail gas temperature at 80±3°C, and collect the discharged particles. Sieve the discharged particles, send the particles with a particle size greater than or equal to 1.5mm to the crusher for crushing, and then mix the crushed particles with the particles with a particle size smaller than 1.5mm obtained by screening and spray them into the fluidized bed again Keep the tail gas temperature in the dryer at 80±3°C, collect the discharged particles and sieve out the particles with a particle size of less than 1.5mm, which are L-lysine feed additives. After the particles with a particle size greater than 1.5mm are crushed again, they are mixed with the discharged pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com