Coke dry quenching slope air course supporting brick overhaul construction process

A construction process and dry quenching technology, used in coke ovens, petroleum industry, coke cooling, etc., can solve problems such as inconvenience of supporting bricks, and achieve the effects of reducing maintenance costs, saving production costs and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0046] The CDQ slanted air duct support brick maintenance construction process of the present invention comprises the following steps:

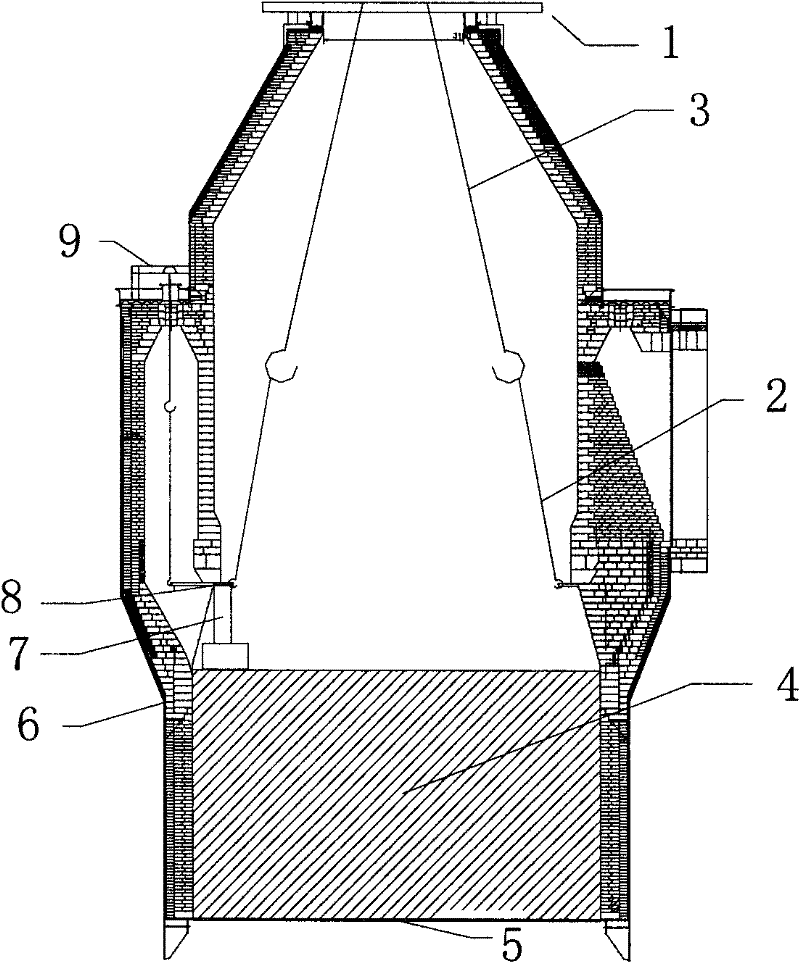

[0047] a) Install the ceiling support device

[0048] see now figure 1 , figure 1 It is a schematic diagram of the ceiling supporting device of the embodiment of the present invention. As shown in the figure, the chain hoist 2, the wire rope 3 and the overhead brick support 8 are used as a ring-shaped spreader to lift the upper masonry of the inclined air duct over the roof brick, and the direction of self-weight of the annular masonry on the upper part of the inclined air duct pillar is applied. On the contrary, the overall lifting prestressing force prevents the upper part of the masonry from sinking when the inclined air duct pillars are disassembled during construction, and the lower part of the roof brick is supporte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com