Method and inspection device for testing containers

A technology for detecting devices and containers, which is applied in the directions of sealing containers tightly with caps, bottle/container caps, and optical testing for flaws/defects, etc., which can solve problems such as damage to anti-tampering security elements and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

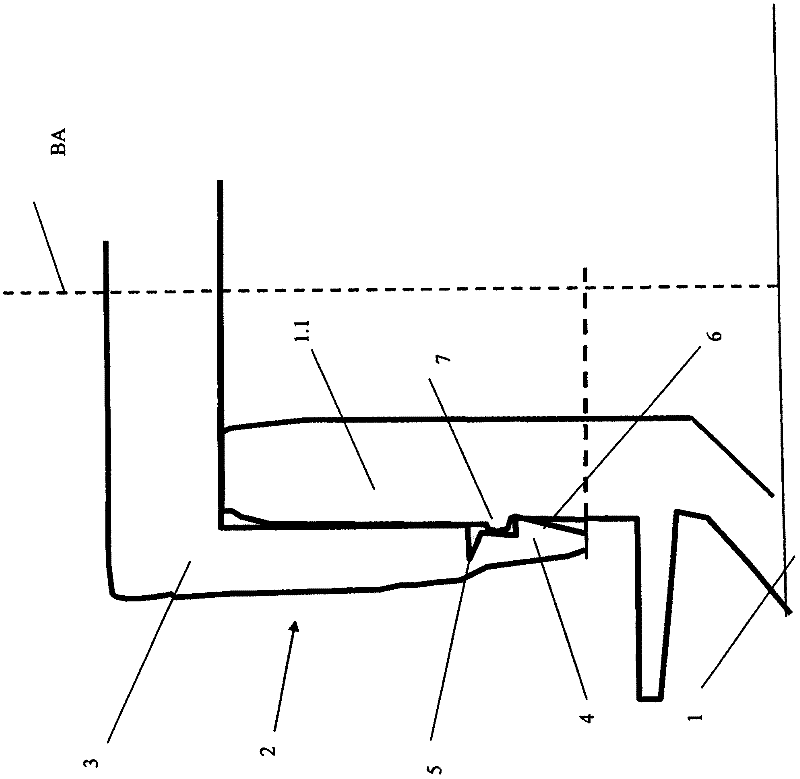

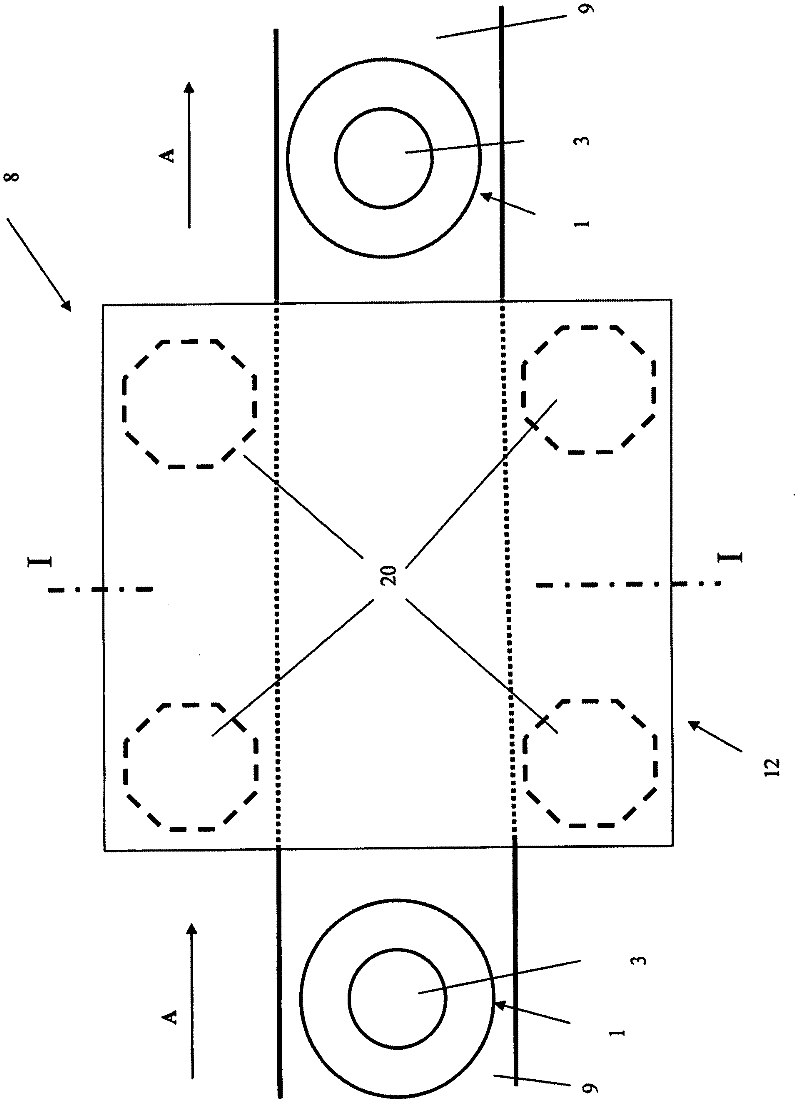

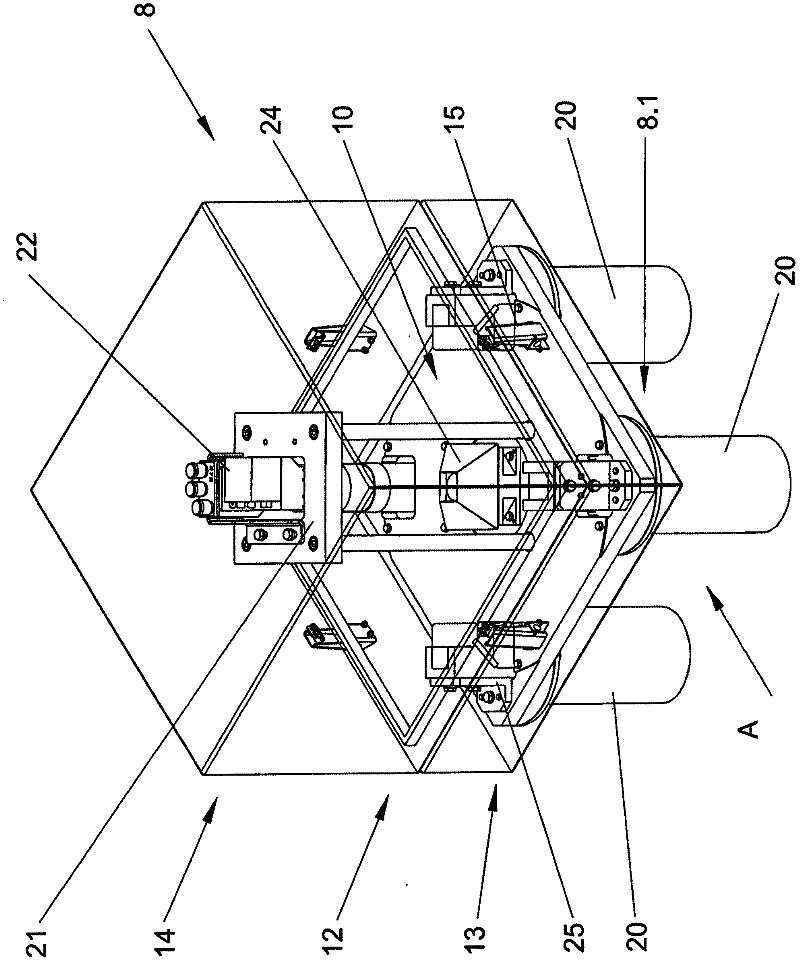

[0013] In the figures, reference numeral 1 denotes a container in the form of a bottle, wherein said container is preferably made of a light-transmitting or translucent material, such as glass or translucent plastic (such as PET), and said The containers are subsequently filled with bulk products such as beverages, which are respectively closed by cap-shaped container closures 2, for example by screwing the container closure 2 or the closure body 3 of the container closure onto the external thread of the container neck 1.1.

[0014] Each container closure 2 consists in a known manner of a cap-shaped closure body 3 and a tamper-evident security ring 4 integral with the closure body 3 via an annular predefined breaking line 5 Formed, wherein the breaking line concentrically surrounds the envelope and the container axis BA, the breaking line is formed by perforation, wherein a plurality of slit-shaped fractures are sequentially arranged along the predetermined breaking line 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com