Mounting device for aircraft engine and mounting method for aircraft engine

A technology for aircraft engines and installation devices, which is applied in the field of mechanical products and aircraft manufacturing, and can solve problems such as high labor intensity, low work efficiency, and low docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

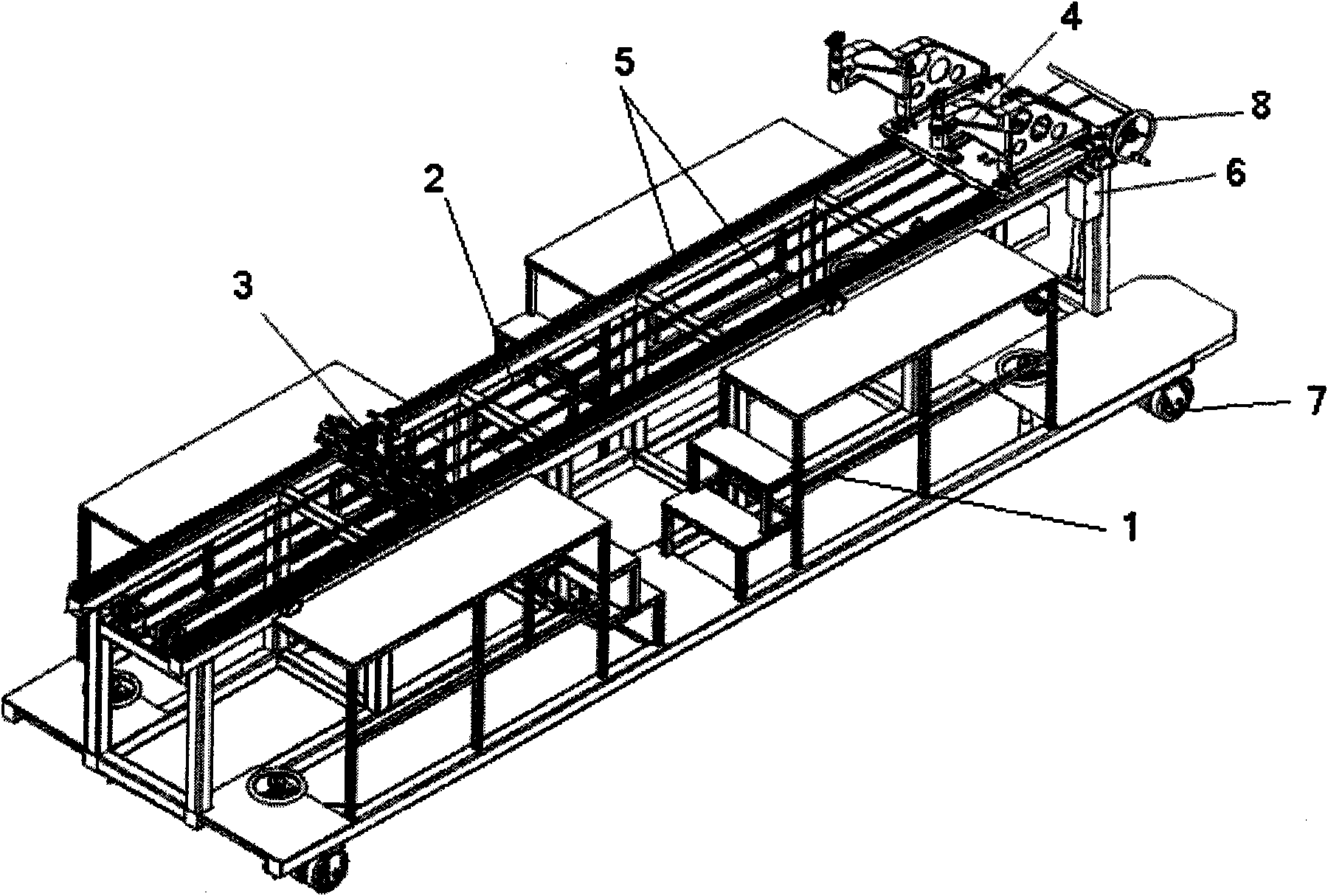

[0011] Referring to the accompanying drawings, the frame body 1 of the engine mounting device is welded by rigid materials, and movable rollers 7 are installed at the bottom for moving the entire device; The horizontal slide track is provided with a working platform and a working ladder on the frame body on both sides of the guide rail body; the fixed support of the engine contains two independent support assemblies, the front support assembly 3 and the rear support assembly 4; the front support assembly The seat assembly 3 is slidably connected with the guide rail body 5 through the slider, and the rear support assembly 4 is not only slidably connected with the guide rail body 5 through the slider, but also connected with the chain transmission mechanism 2; the chain transmission mechanism 2 is arranged on the side of the two horizontal slide rails Between the rail bodies 5, the chain transmission mechanism 2 is driven by the motor 6.

[0012] This device drives the chain tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com