Alkali cleaning system for filter cloth of press filter and cleaning method thereof

A filter press and alkali cleaning technology, which is applied in the filter cloth alkali washing system of the filter press and its cleaning field, can solve the problems of prolonged washing time of the filter cake, difficulty in thoroughly cleaning the filter cloth, and decreased production capacity, and achieves convenience in implementation, Good cleaning effect and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

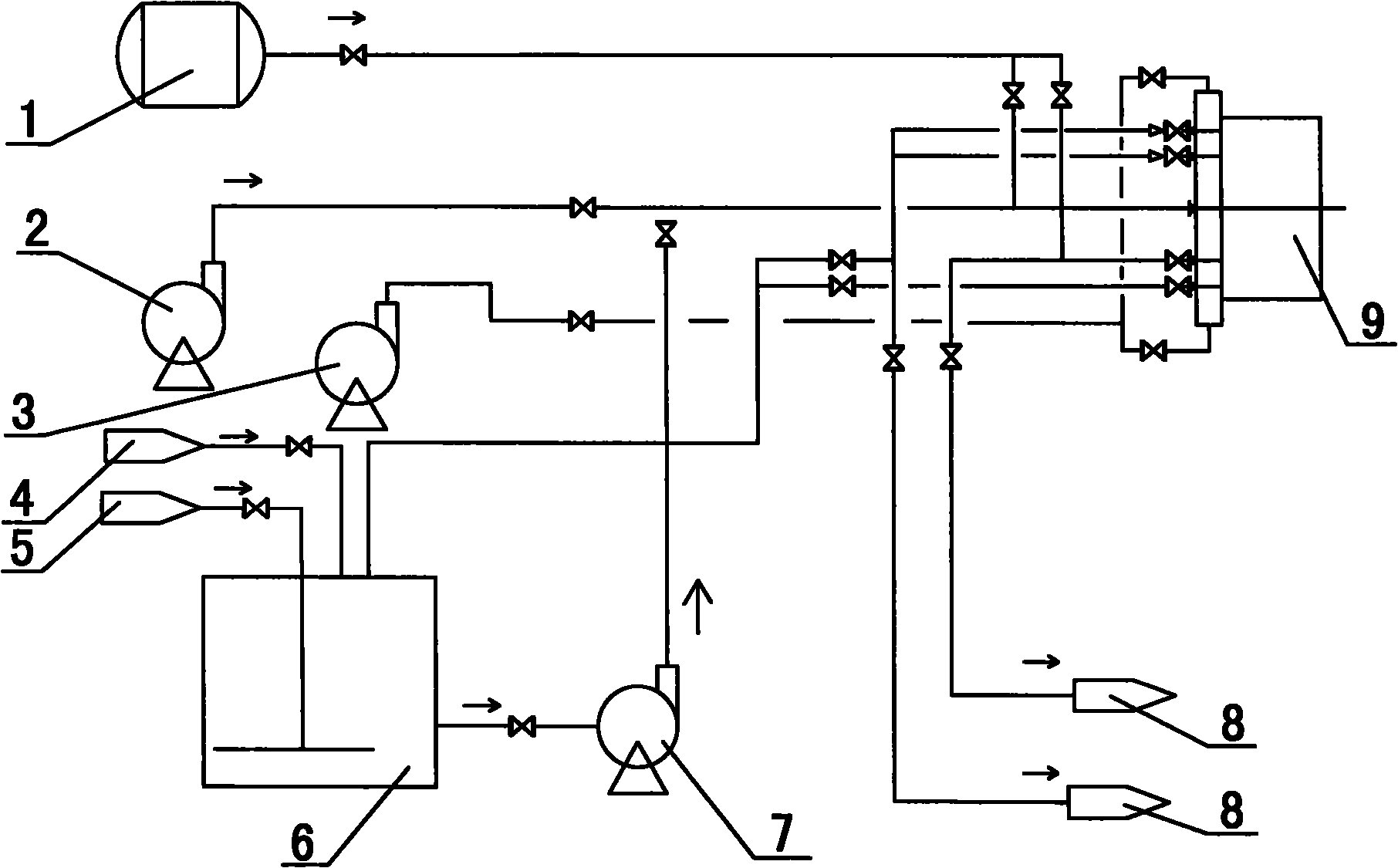

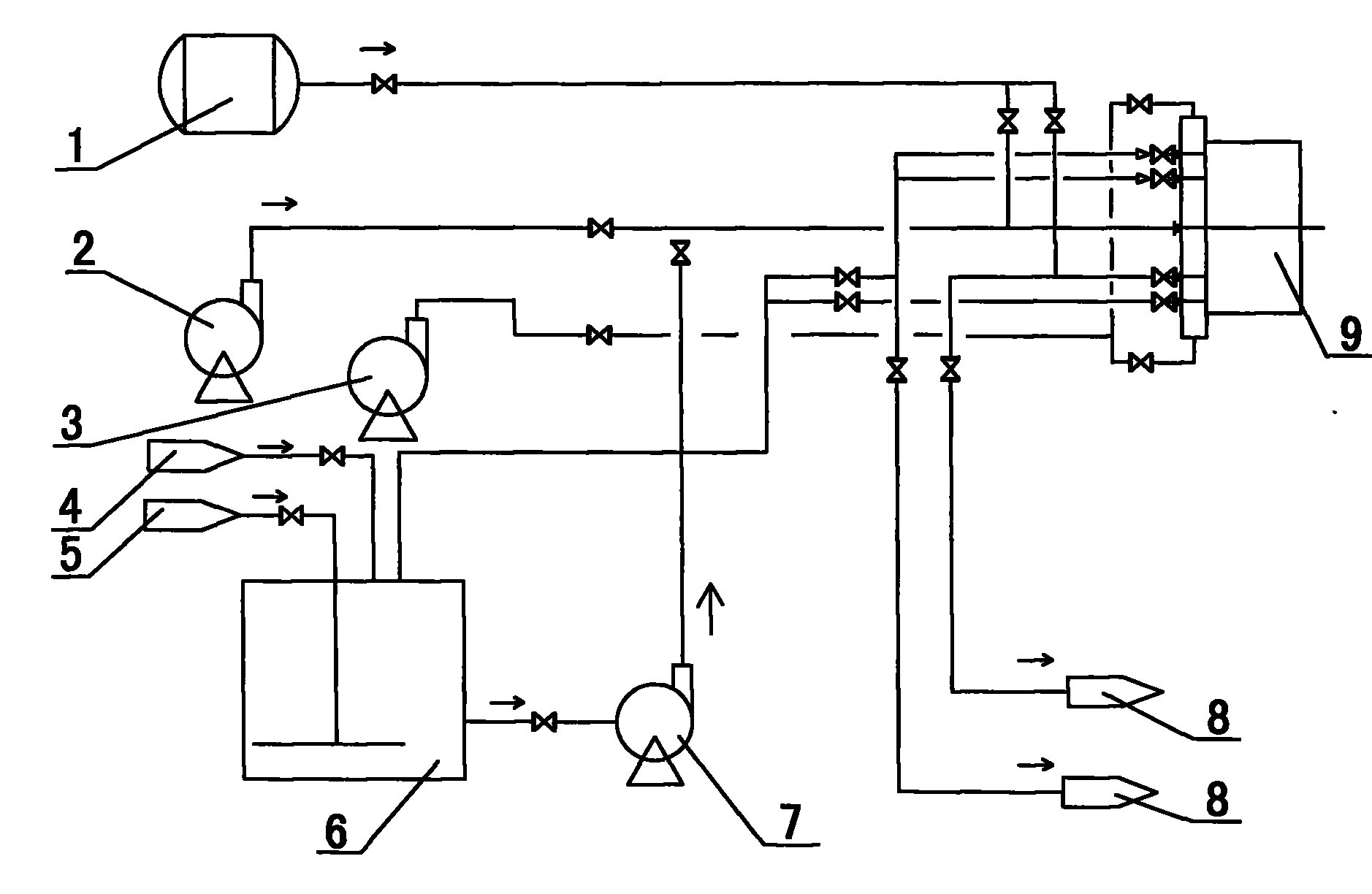

[0021] like figure 1 As shown, a specific embodiment of the present invention is provided, figure 1 In the process, the entire alkali cleaning system is connected through pipelines, and corresponding valves are installed in each pipeline, and the output pipeline of the filter press feed pump 2 is connected with the output pipeline of the alkali cleaning pump 7 and the output pipeline of the compressed air storage tank 1. Filter press 9, another output pipeline of the compressed air storage tank 1 is connected to the sewage treatment pool 8 after converging with the drain pipe of the filter press 9, and the alkali tank 6 is externally connected with a process water pump 4 and a steam pump 5, and a lye The return pipe is connected to the filter press 9, and the other pipe is connected to the alkali washing pump 7.

[0022] The alkali cleaning method of this invention comprises the following steps:

[0023] a. Configure lye; check that the liquid level in the alkali tank 6 must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com