Washing and dehydrating machine capable of automatically unloading

An automatic unloading and de-drying machine technology, applied to washing devices, other washing machines, washing machines with containers, etc., can solve the problems of high labor intensity and easy torn linen, etc., to reduce labor intensity and lower labor intensity , The effect of saving washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

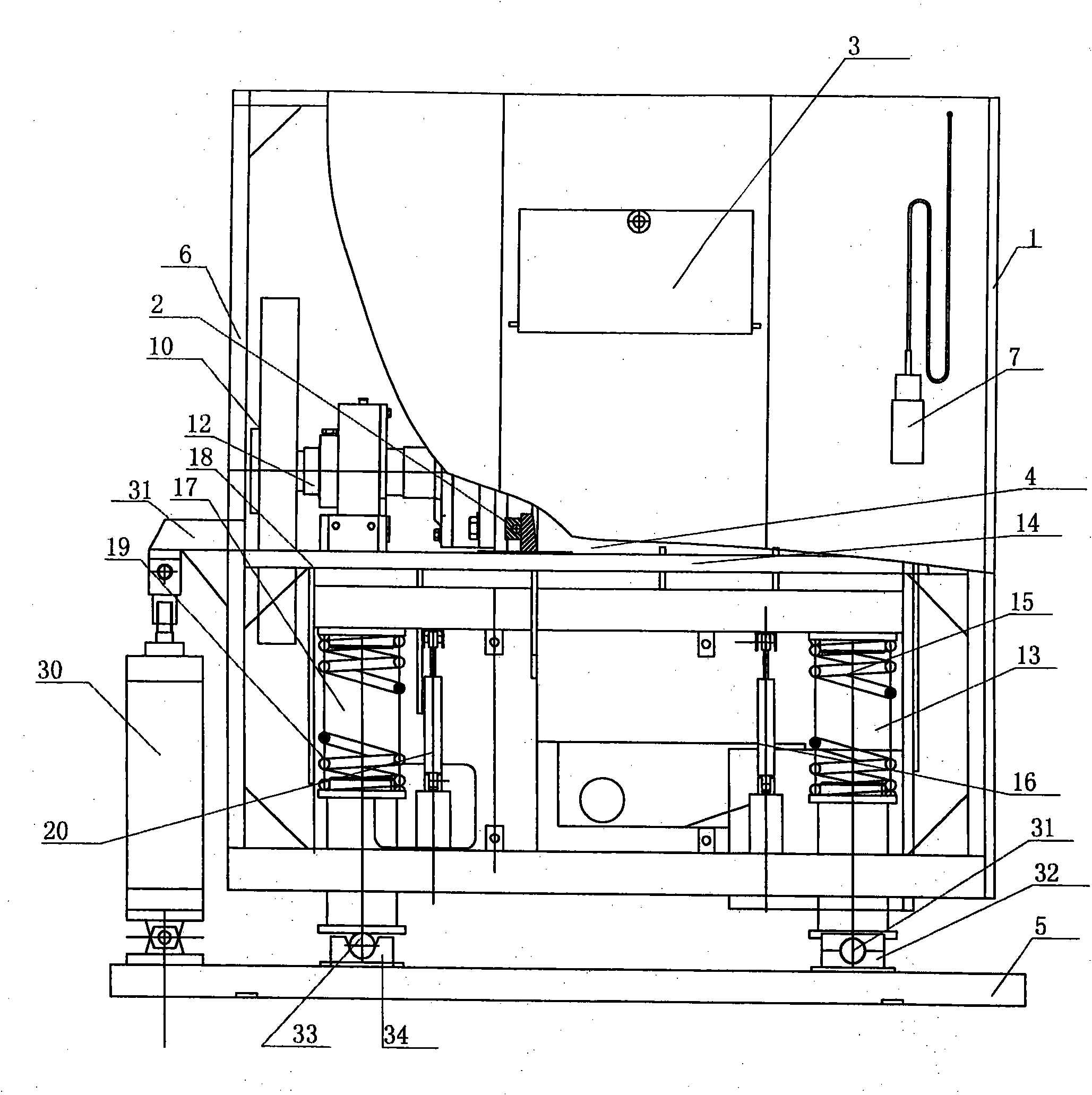

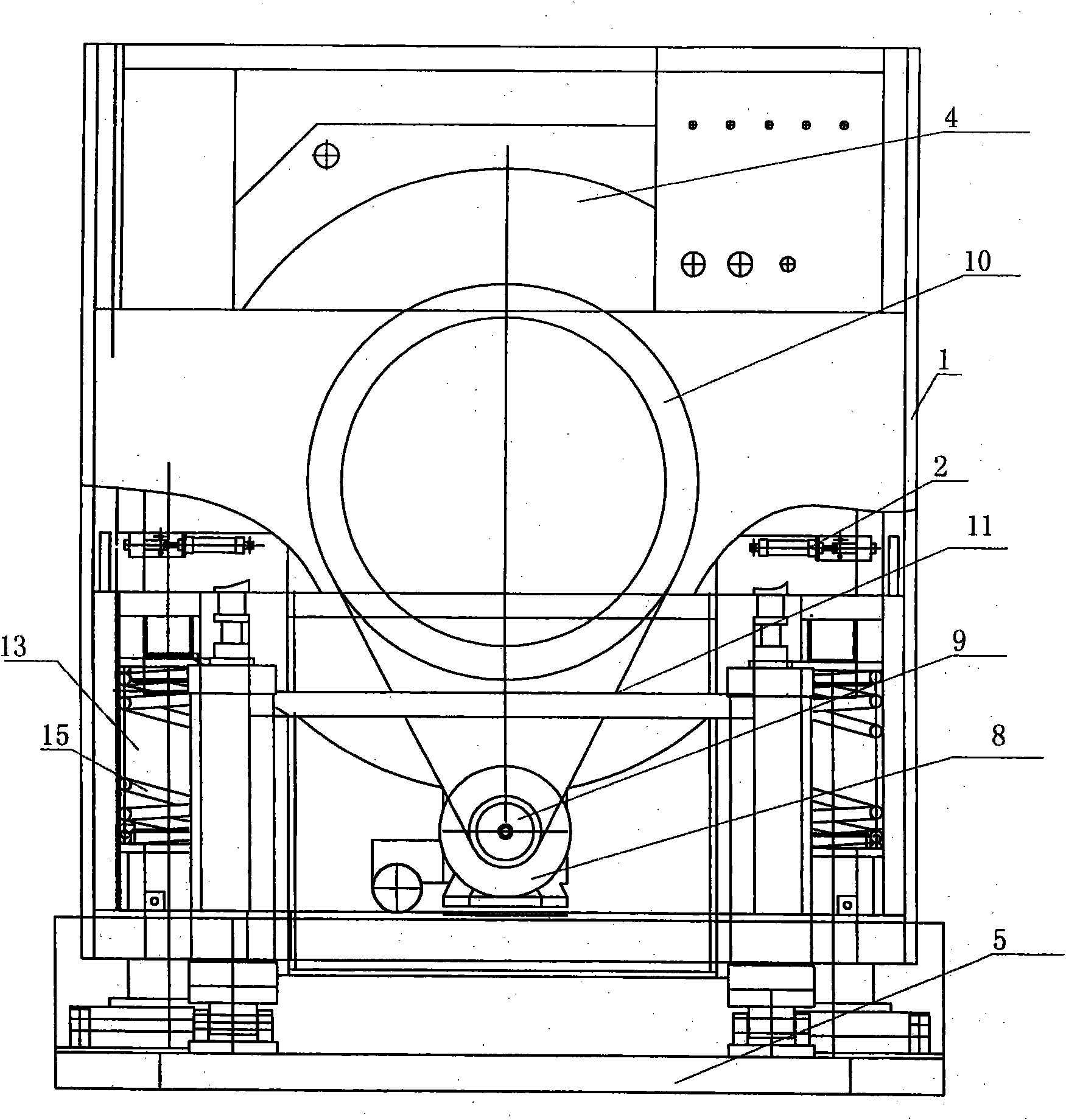

[0012] exist figure 1 , figure 2 , image 3 and Figure 4 , the present invention is an automatic unloading washing and drying machine, which is provided with a housing 1, a dosing box 3 is provided on the side of the housing 1, and a washing device is provided in the housing 1, and the washing device includes a washing cage 4 And transmission device, transmission device is positioned at the rear portion of washing cage 4, and transmission device comprises motor 8, transition wheel 9, driving wheel 10, and transition wheel 9 is sleeved on the output shaft of motor 8, passes between transition wheel 9 and driving wheel 10 Drive belt 11 is connected, and the center of driving wheel 10 is worn with transmission shaft 12, and driving wheel 10 is connected with washing basket 4 by transmission shaft 12, and motor 8 drives washing basket 4 to rotate through transition wheel 9, driving wheel 10 and transmission shaft 12 successively, so The bottom of the washing device is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com