Bronzing and concave-convex one-time forming method

A molding method and concave mold technology, applied in gold powder printing, printing, rotary printing machines, etc., can solve the problems of easy generation of waste products, inaccurate positioning of printed products, low efficiency, etc., and achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

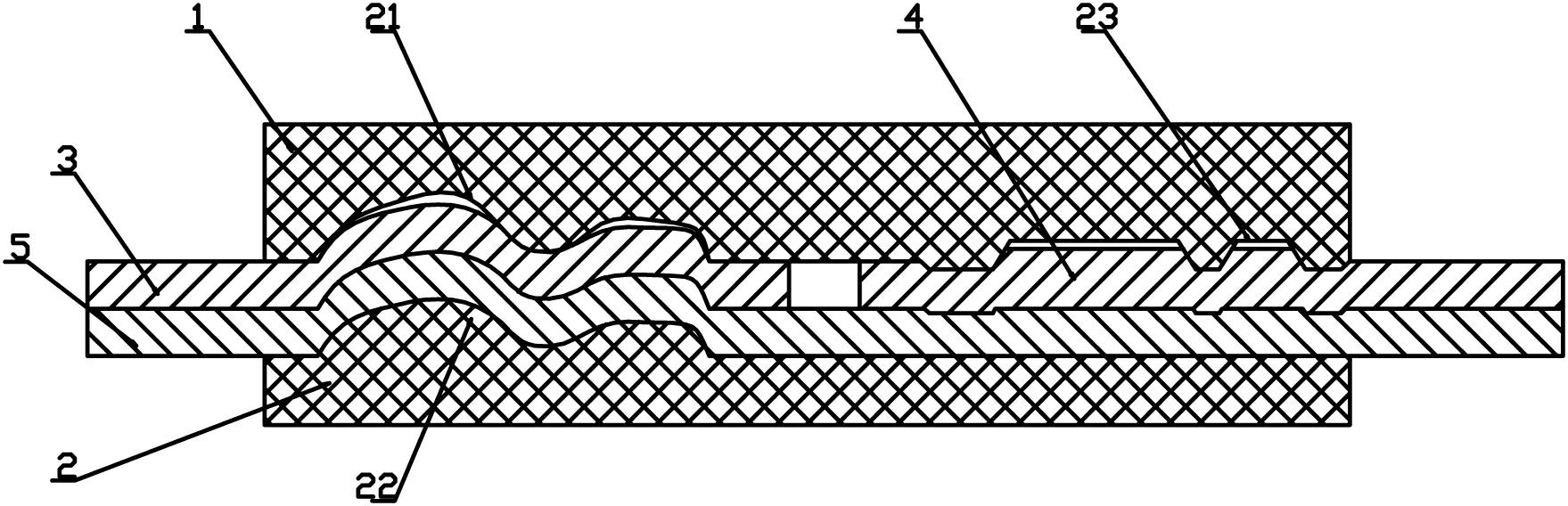

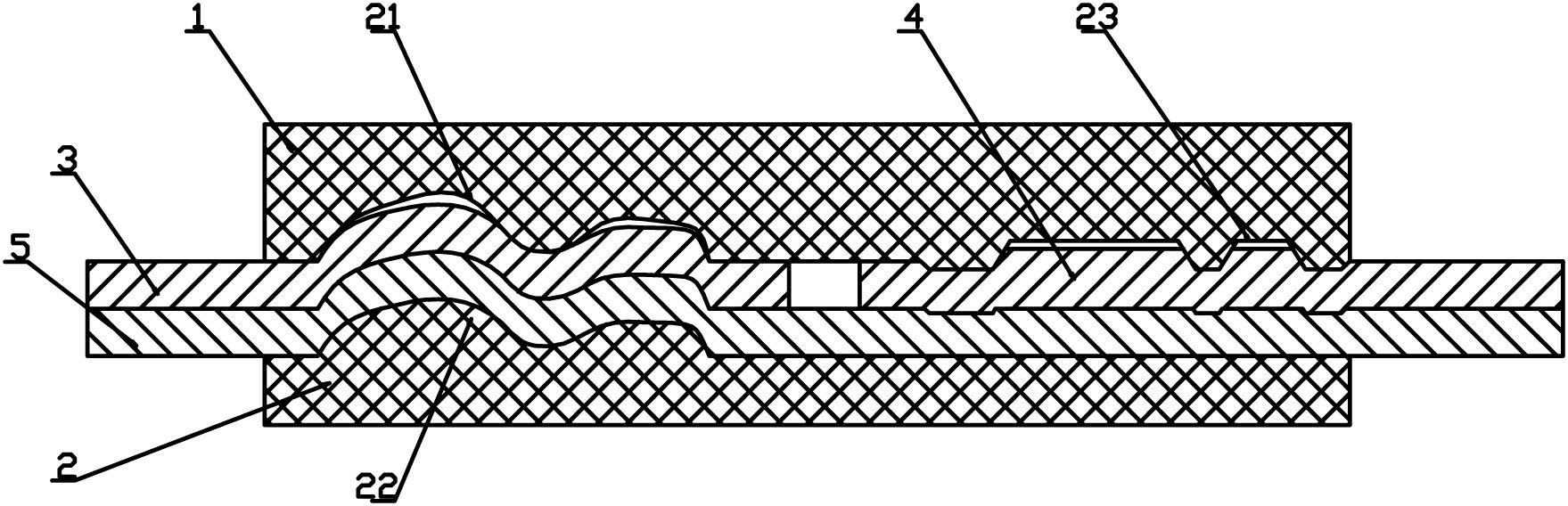

[0015] Such as figure 1 Among them, a bronzing embossing one-time forming method comprises the following steps:

[0016] 1) Make the die 21, the punch 22 and the stamping plate 23 on the upper die 1 and the lower die 2 of the same group;

[0017] 2) heating the upper mold 1 and / or the lower mold 2 to a temperature for bronzing;

[0018] 3) A heat insulating layer 3 is provided between the concave mold 21 or the convex mold 22 and the printed matter 5;

[0019] 4) A hot stamping transfer layer 4 is set between the hot stamping plate 23 and the printed matter 5;

[0020] Through the above steps, one-time molding of hot stamping and concave-convex processing is realized.

[0021] The heat insulation layer is a thin material that can withstand a temperature of 80°-120°C and has elasticity.

[0022] The heat insulation layer is rubber or rubber cloth, and the thickness of the heat insulation layer is usually below 1mm. After testing, the setting of the heat insulation layer ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com