Phonon function material structure containing non-convex type section holes and making method thereof

A technology of functional materials and production methods, applied in the direction of sound-generating devices, instruments, etc., can solve the problems that cannot meet the requirements of acoustic characteristics, and achieve the effect of simple processing and wide acoustic band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

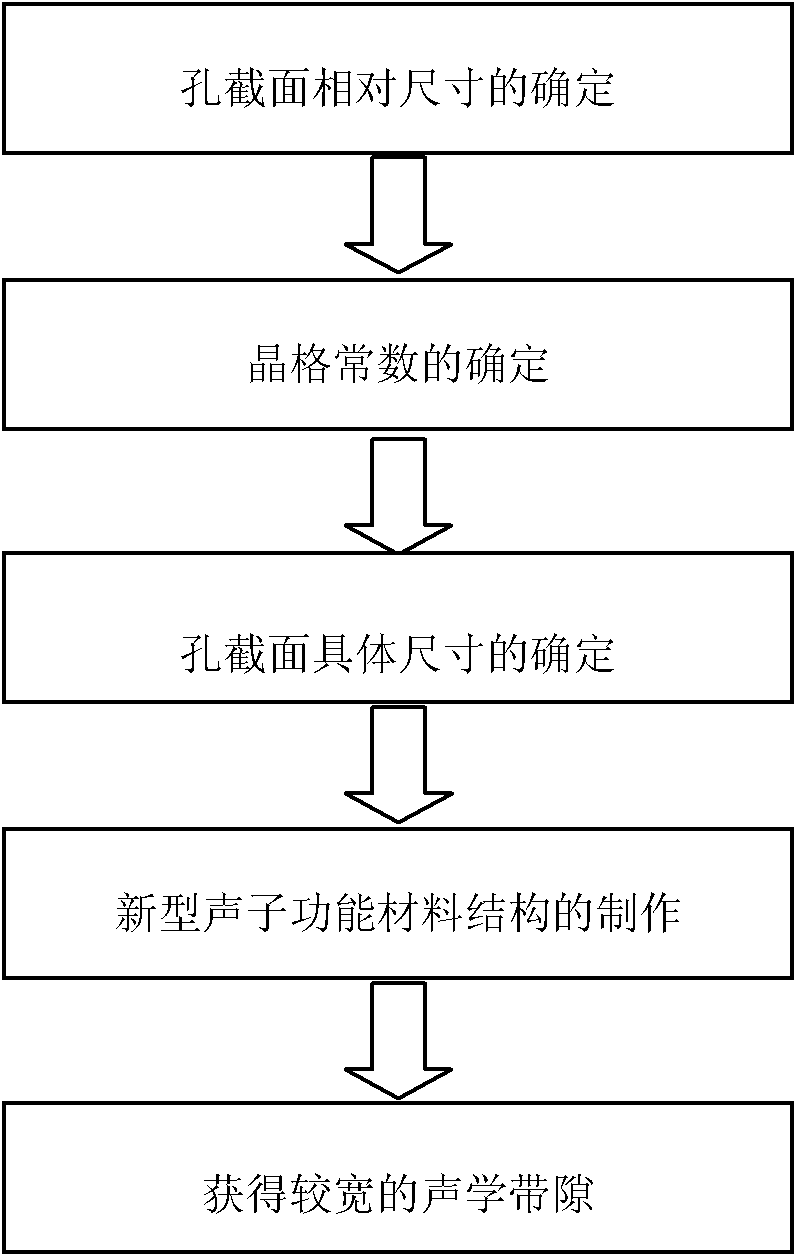

[0029] A method for manufacturing a novel phonon functional material structure containing non-convex cross-sectional holes is characterized in that it further includes the following steps:

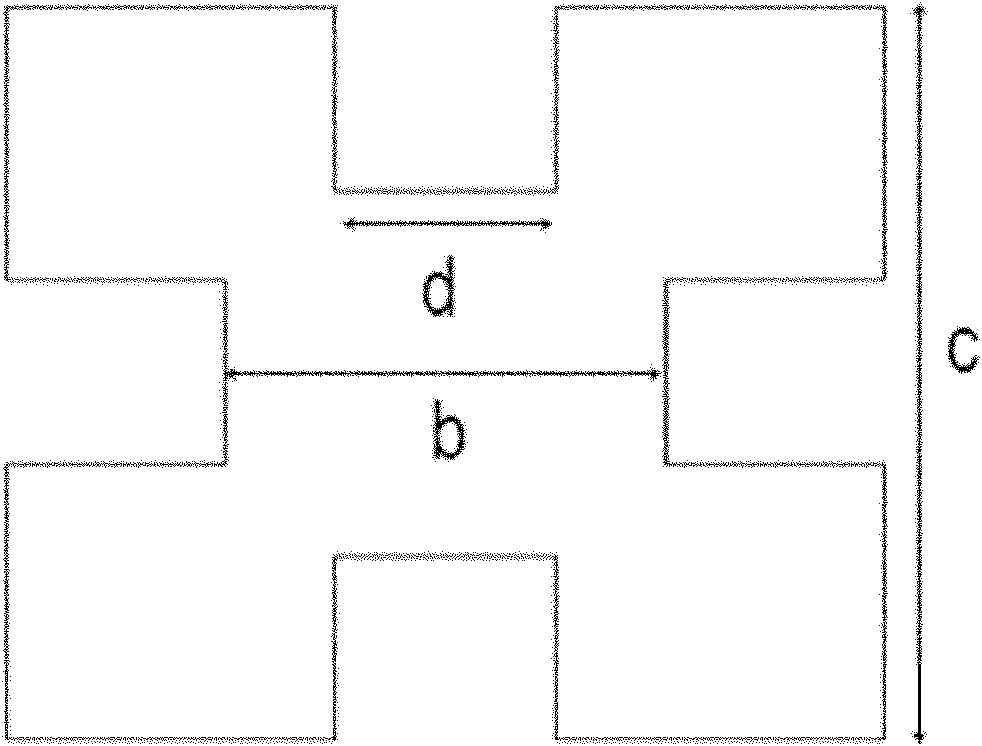

[0030] Step 1: Preliminary design of the relative size of the non-convex cross-section hole: the schematic diagram of the hole cross-section is as follows figure 2 As shown, record the non-convex cross-section hole section size as b, c and d, and determine the maximum value of c / a according to the requirements of structural strength; to obtain a wider acoustic band gap, the hole section size should satisfy b / a=c / a-0.3, this is a necessary condition for the structure to obtain the widest acoustic bandgap; to obtain the widest acoustical bandgap, the rectangle (ie figure 2 The distance between four small rectangles with a length of (c-b) / 2 and a width of d), but the rectangles should be prevented from touching each other during vibration. Assuming that the strain of the material does not ...

Embodiment 2

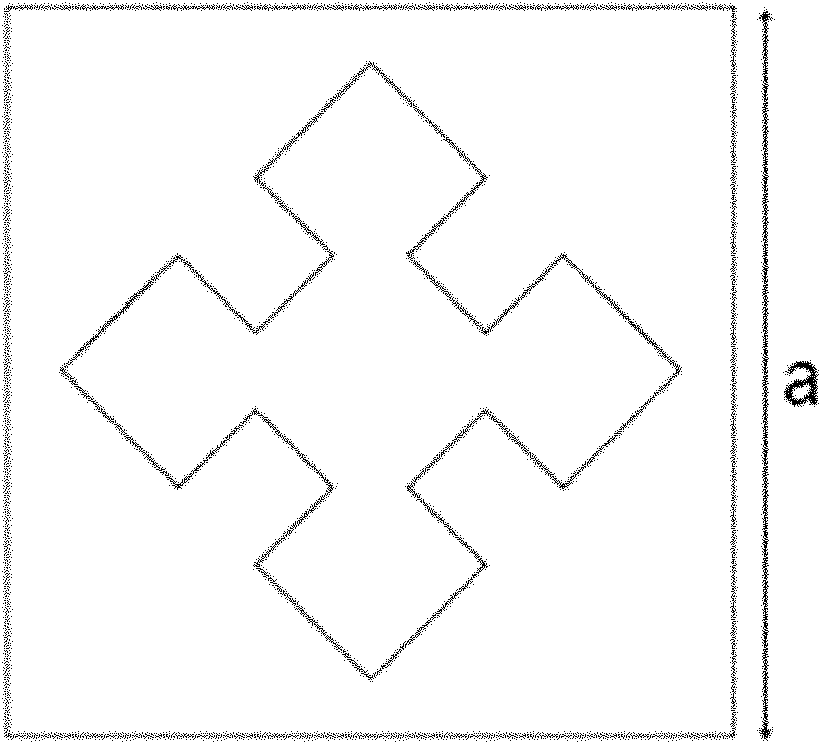

[0037] Hole section diagram as figure 2 As shown, according to the required porosity and structural strength, determine the relative size of non-convex section holes; image 3 The determination of the lattice constant in the medium should meet the requirements of the structural acoustic properties; drill holes in a given matrix, adjust the symmetry of the structure, and form such Figure 4A new type of phononic functional material structure containing non-convex cross-sectional holes is shown, wherein the non-convex cross-sectional holes are arranged in a close-packed form in the structural period direction; image 3 for Figure 4 The schematic diagram of the original cell.

[0038] Assume that the required porosity of the structure is The requirement for structural strength is c / a≤0.7; from step 1, b / a=0.4, d / a=0.398, and at this time Therefore, the relative size of the hole section should be determined according to step 2; that is, the simultaneous equation 0.7 2 +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com