Equipment matching method for fully mechanized mining working surface with large mining height

A fully mechanized mining face and working face technology, applied in mining equipment, earthwork drilling, cutting machinery, etc., can solve problems such as waste of coal resources, increased eccentric load of supports, and increased loss of triangular coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

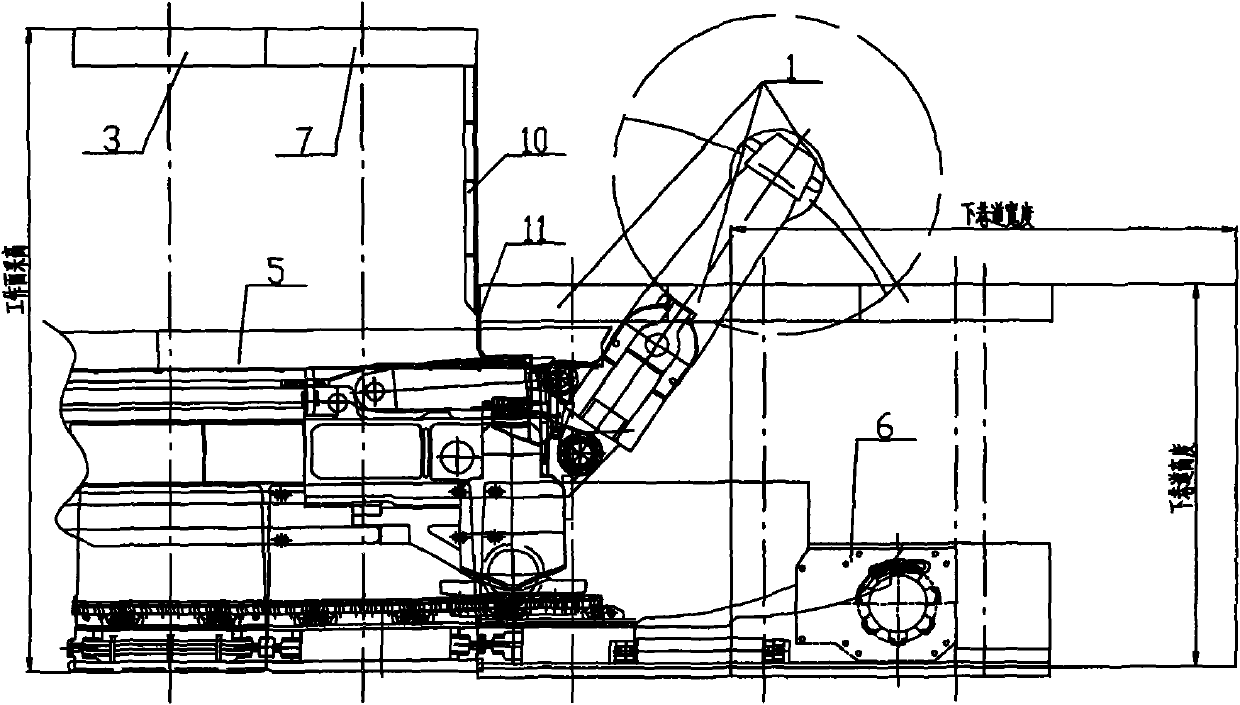

[0009] Such as figure 1 , 2 , 3, the matching of the large mining height fully mechanized mining face equipment of the present invention includes a terminal support 1, a special terminal support 2, a transition support 3, a working face support 4, a shearer 5, and a scraper conveyor 6 matching. The roadways at both ends of the large mining height working face are supported by the end bracket 1. The center of the special end bracket 2 is shifted down the roadway to ensure the installation space of the large side guard plate 8 of the special end bracket 2. The large side guard plate 8 overlaps with the side guard plate 9 of the adjacent end bracket 1 and directly has a large gradient Transition to the mining height of the working face, and the other side overlaps with the 3 side guard plates of the transition bracket to ensure the safety protection of the working face. Transition support 3 adopts the untimely support method, and the top beam of the support is lengthened to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com