Fuel injection valve for internal combustion engine and method of manufacturing the same

A technology of fuel injection valve and internal combustion engine, which is applied to fuel injection device, special fuel injection device, internal combustion piston engine, etc., can solve the problems of rising cost, increasing the number of injection holes, complicated manufacturing process, etc., and achieve the effect of inhibiting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

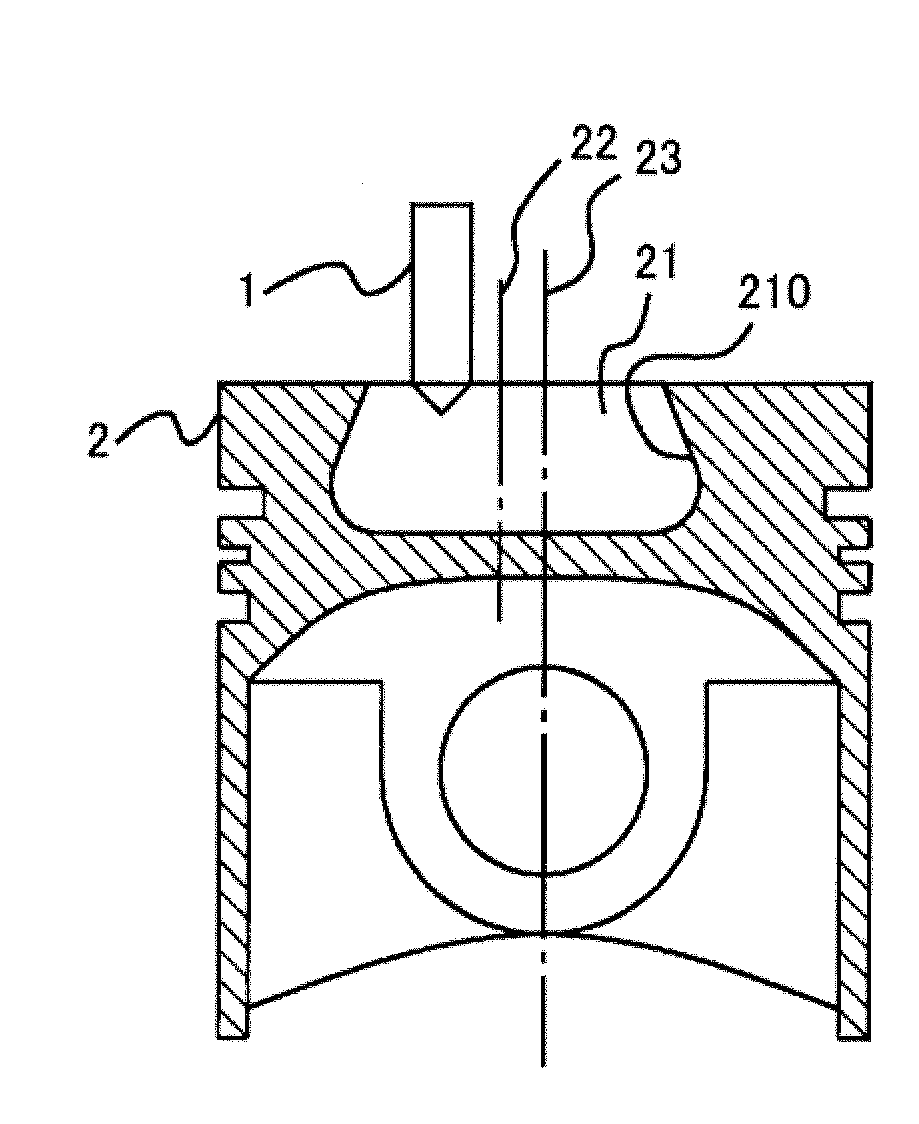

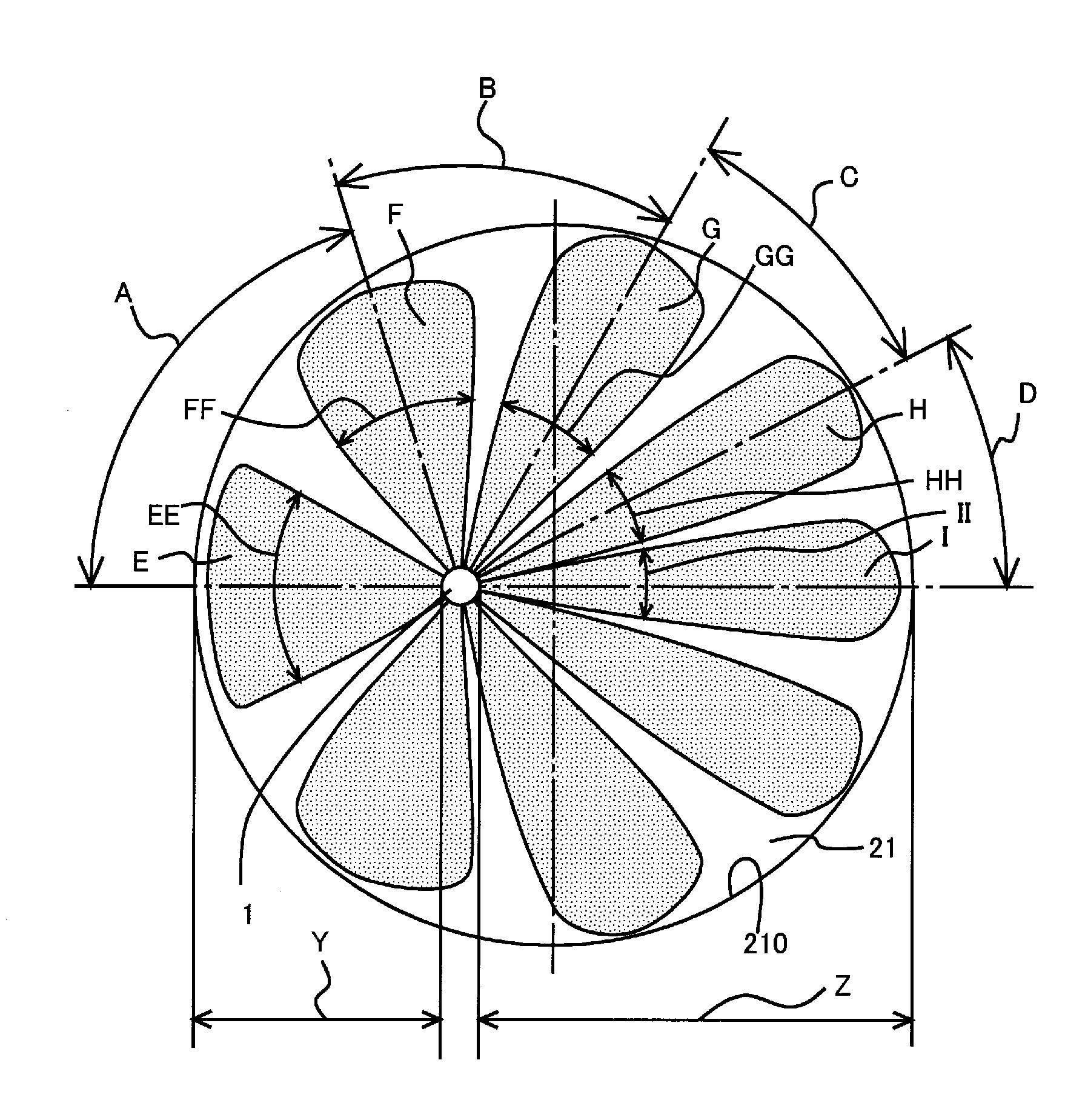

[0039] figure 1 is a diagram showing the positional relationship between the fuel injection valve 1 and the piston 2 according to the present embodiment. Should figure 1 It is a cross-sectional view of the piston 2 cut along the cylinder axis when the piston 2 is located near the top dead center. A combustion chamber 21 is formed on the upper surface of the piston 2 so that a part of the upper surface is recessed into the piston 2 . The combustion chamber 21 is formed such that the cross section formed by the plane perpendicular to the central axis of the piston 2 is circular. Also, the central axis 22 of the combustion chamber 21 and the central axis 23 of the piston 2 are parallel and spaced apart.

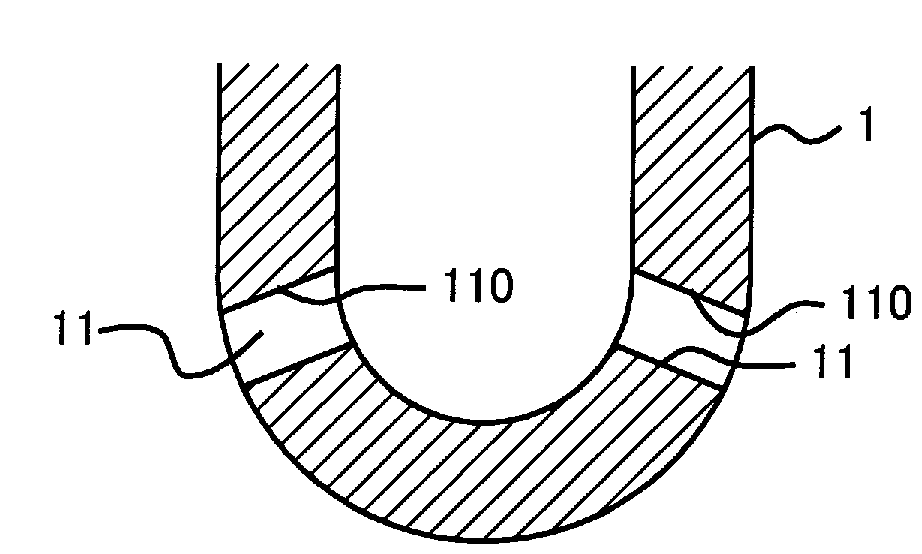

[0040] The fuel injection valve 1 is mounted spaced apart from the central axis 22 of the combustion chamber 21 . here, figure 2 is a longitudinal sectional view of the vicinity of the front end of the fuel injection valve 1 according to the present embodiment. The fuel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com