One-off forming machine for sewing-up valve sack double openings

A valve pocket and forming machine technology, applied in envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of many occupants, unstable production quality, low efficiency, etc. High efficiency and the effect of ensuring suture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

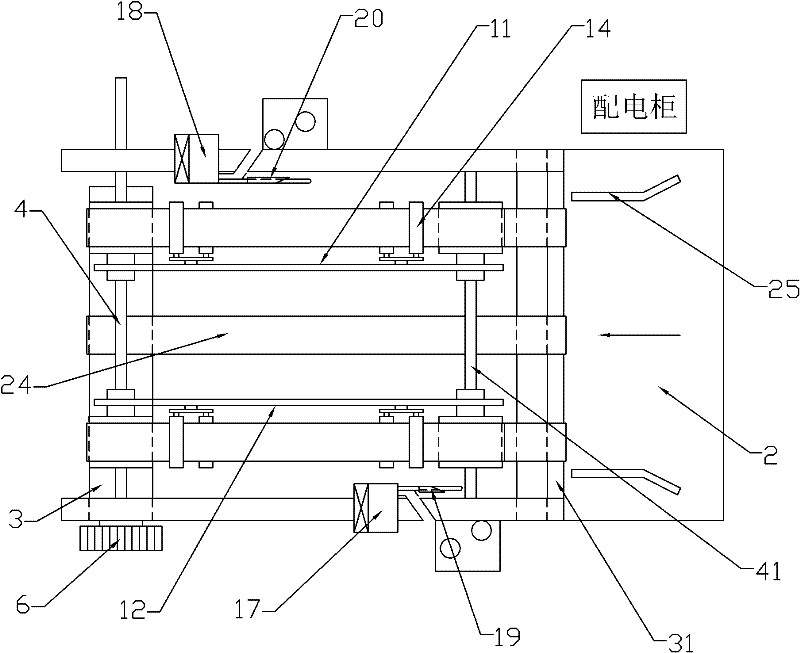

[0018] Such as figure 1 , figure 2 , image 3 shown. The valve bag double-slit one-time molding machine includes a frame 1 and a workbench 2 arranged on the frame. The frame 1 is welded as a whole with a square steel structure. The extent to which the front and rear ends of the workbench 2 protrude outside the frame 1 is determined according to actual needs. The side of the feed port 26 of the valve pocket is extended outward to facilitate the valve pocket. Feed operation.

[0019] The drive roller 3 and the driven roller 31 connected by the lower conveyor belt 16 are arranged on the frame 1. There are three conveyor belts connecting the drive roller 3 and the driven roller 31. Their movement modes and mechanism settings are all the same. The lower conveyor belt 16 on the side and the third lower conveyor belt 24 in the middle of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com