Cleaning device and coating device for slit nozzle

A slit nozzle and cleaning device technology, which is applied to spray devices, spray devices, and devices for coating liquid on surfaces, etc., can solve the problems of low cleaning operation efficiency, time-consuming, troublesome and troublesome, etc., and achieve particle suppression. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, preferred embodiments of the present invention will be described with reference to the drawings.

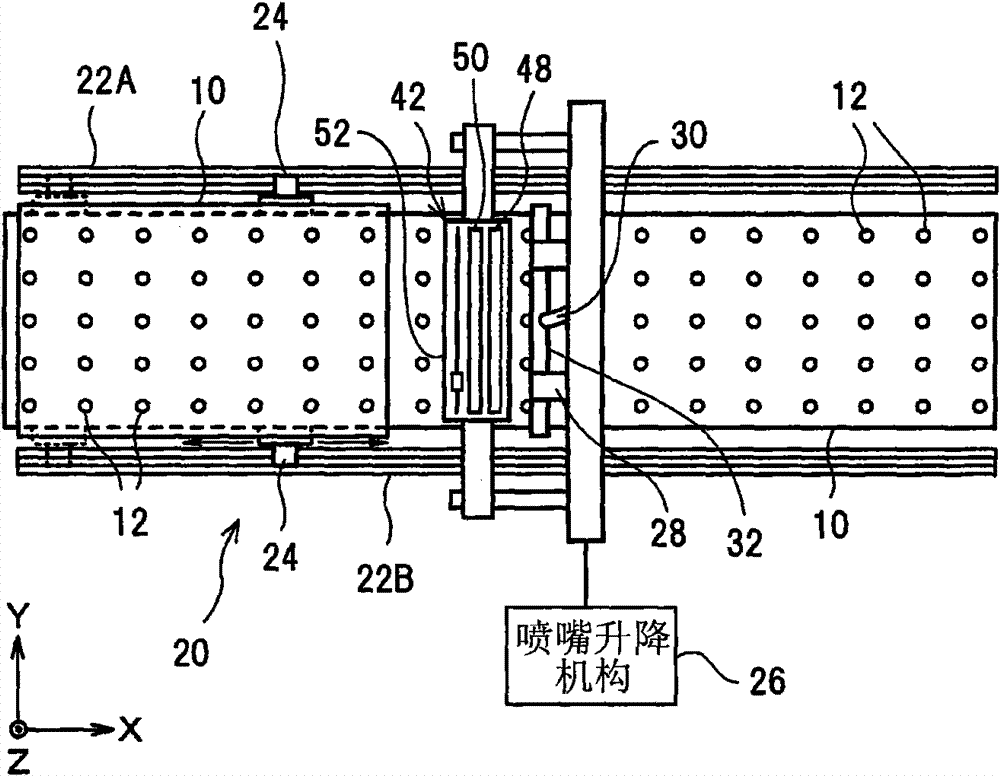

[0042] figure 1 A structural example of a resist coating device to which the slit nozzle cleaning device of the present invention can be applied is shown.

[0043] This non-spin coating coating device has: utilize the pressure of gas to make the substrate to be processed, such as the glass substrate G for FPD floating in the air, the floating workbench 10, for floating on the workbench 10 along the length direction of the floating workbench ( X direction) the substrate conveying mechanism 20 for conveying the substrate G floating in the air, the slit nozzle 32 for supplying the resist liquid to the upper surface of the substrate G conveyed on the floating table 10, and the slit nozzle 32 for supplying the substrate G in the coating process. The nozzle regeneration part 42 regenerates the slit nozzle 32 between intervals.

[0044] The upper surface of the floating tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com