Method for integrally, nakedly and radially casting disk type radiation type magnetic conduction iron core

A casting method and radiation-type technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as product performance degradation, stem burnt products, and damage to the physical and mental health of operating personnel, so as to reduce temperature rise and Effects of no-load loss, slowing down insulation aging speed, and protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

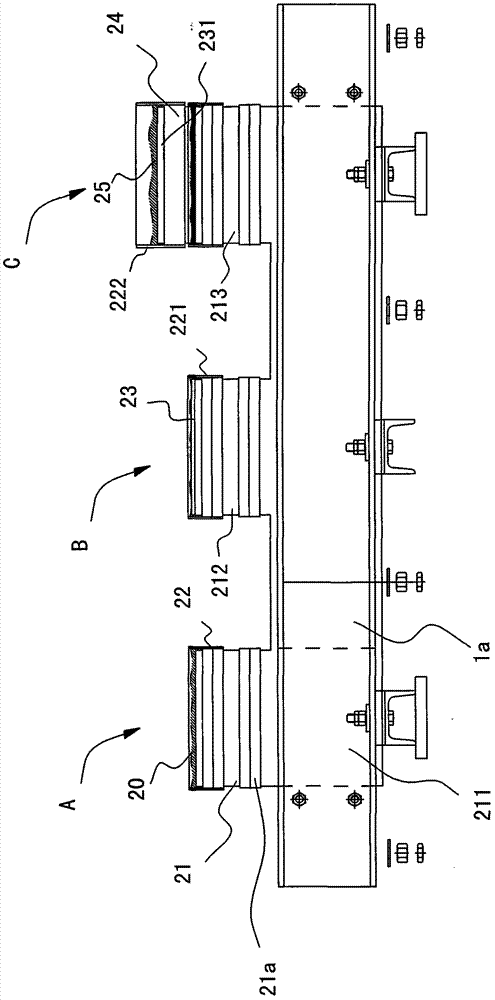

[0023] The integral bare casting method of the pie-type radiation-type magnetic conducting core includes the steps of separately manufacturing an air gap plate, an upper iron yoke blank, a lower iron yoke blank, an iron core cake and casting. In the manufacturing process of the present invention, a guiding principle is always implemented: the liquid resin can flow through all the iron core parts, so that the integral casting can be solidified and formed at one time, so that the cured resin can be distributed among the silicon steel sheets like a steel mesh, forming a very Solid solid core.

[0024] Many vertical through-hole processes are added in the manufacture of the air-gap plate, the purpose of which is to allow the liquid resin to pass through the air-gap plate and establish a circulation channel for the liquid resin. The diameter of the through hole is generally 10-15mm.

[0025] The production of the upper iron yoke blank and the lower iron yoke blank is divided into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com