Three-dimensional surface topography measurement device based on one-dimensional Dammann grating

A three-dimensional surface and shape measurement technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high cost of lighting system and high uniformity of light source, so as to avoid low light intensity and improve scanning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

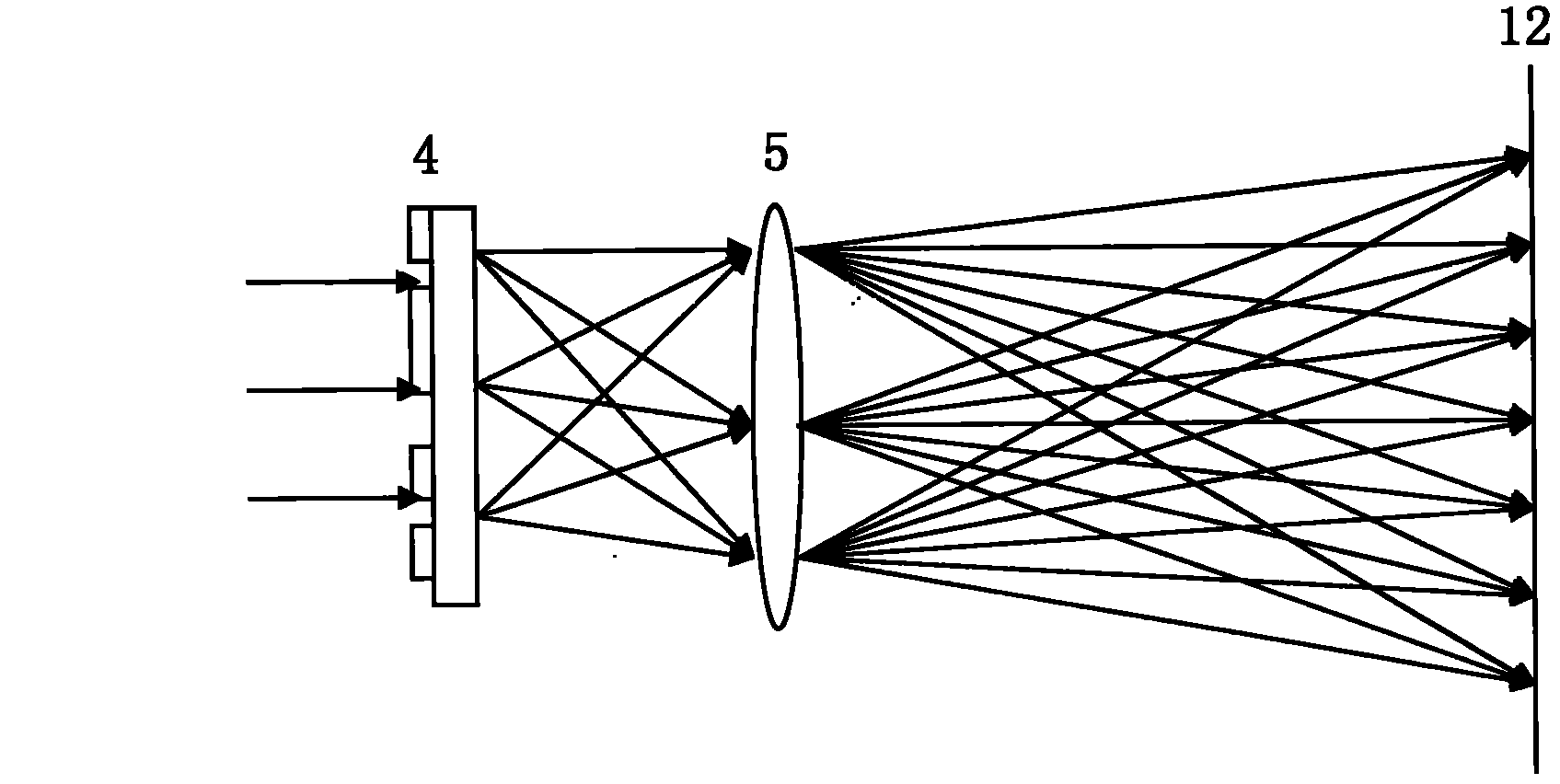

[0021] see first figure 1 , figure 1 It is the schematic diagram of the spectroscopic principle of Damman grating. After the laser beam radiated by the laser light source 1 is collimated by the collimator, the parallel light enters the Daman grating 4 and then is focused on the focal plane 12 by the collimator lens 5 .

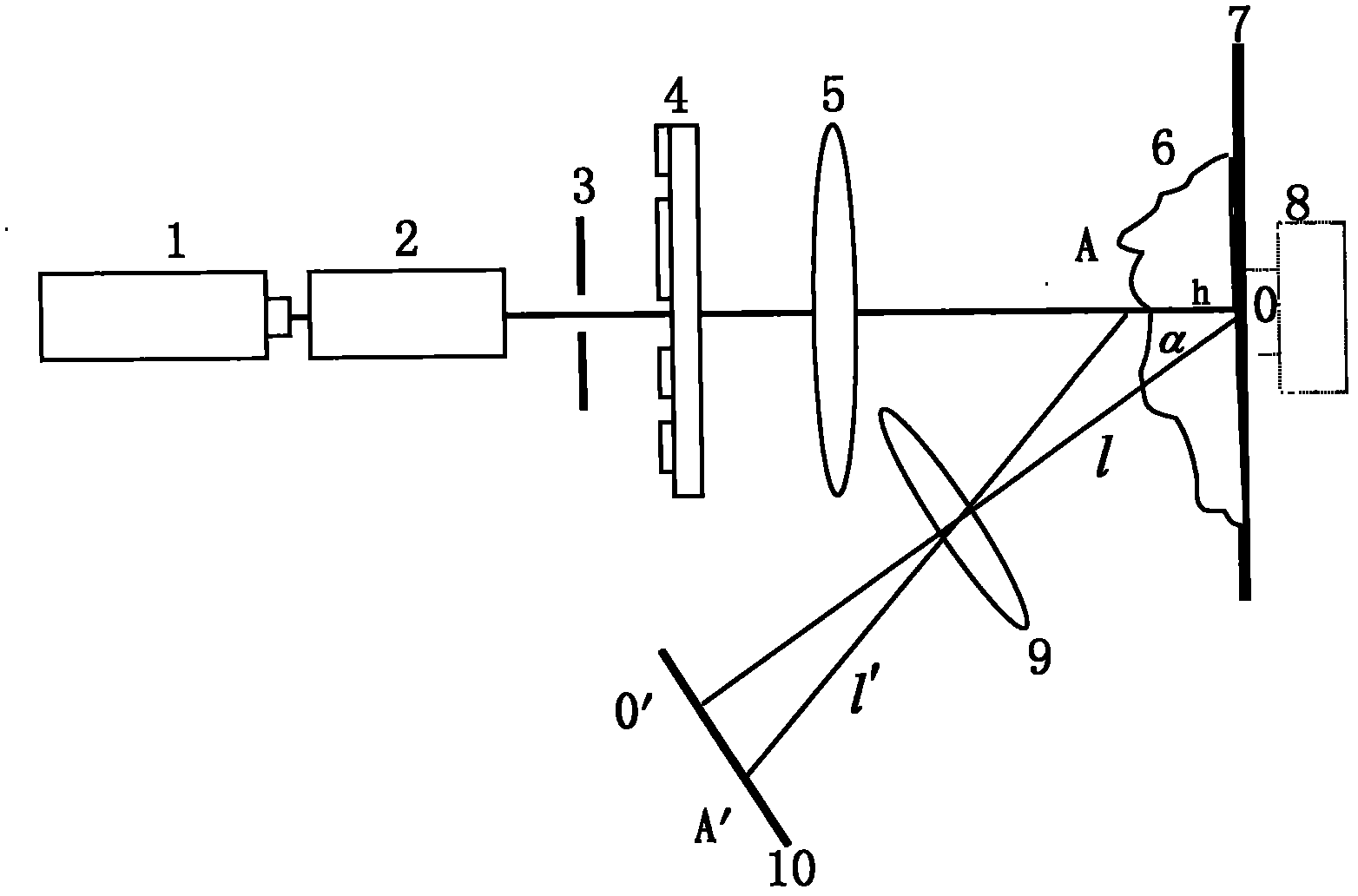

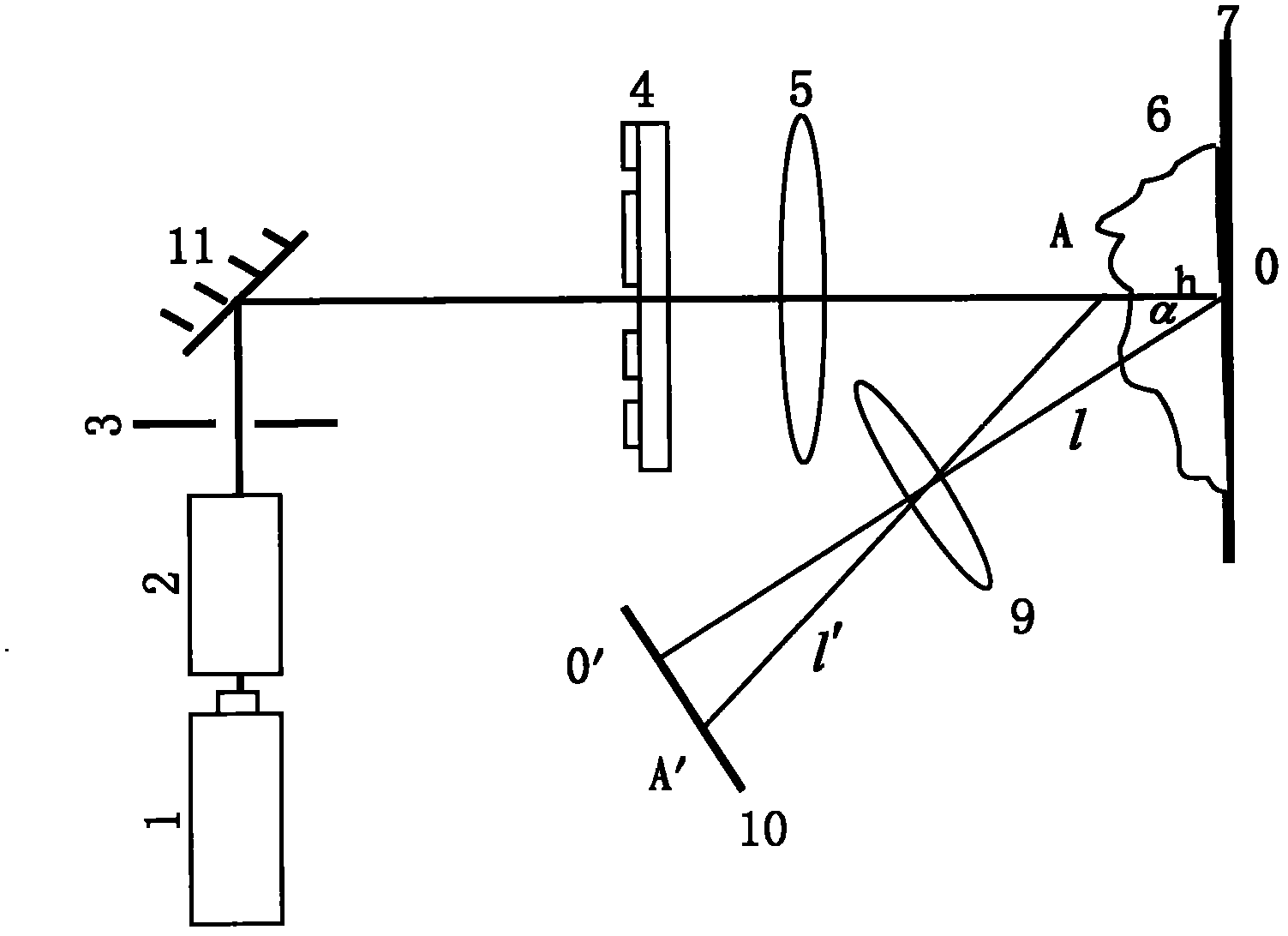

[0022] figure 2 It is a schematic diagram of Embodiment 1 of a three-dimensional surface topography measurement device based on a Damman grating in the present invention. Among them, the Damman grating is fixed, and the measured object is placed on the translation platform for one-dimensional translation to realize additional one-dimensional scanning.

[0023] As can be seen from the figure, the present invention is based on a one-dimensional Daman gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com