Nano-scale three-dimensional shape measurement method based on scanning electron microscope

A technology of scanning electron microscopy and three-dimensional topography, which is applied in the field of precision measurement, can solve the problems of time drift, limited value, and the inability to eliminate the influence of time drift measurement accuracy, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

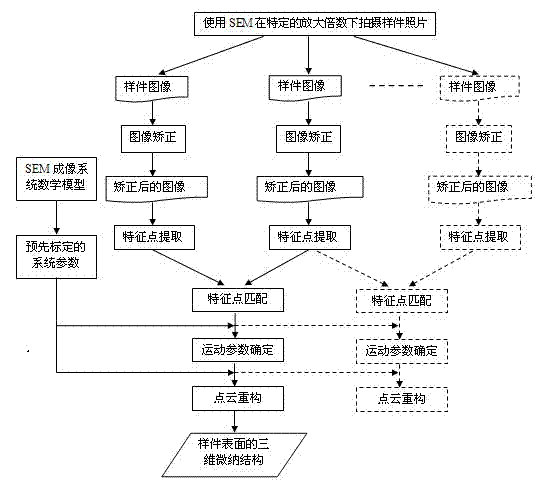

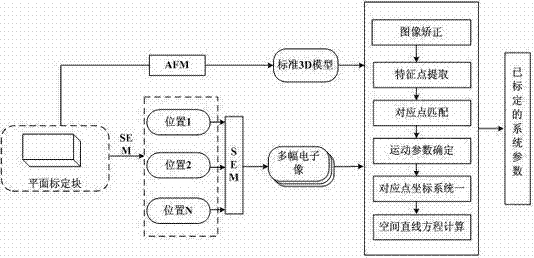

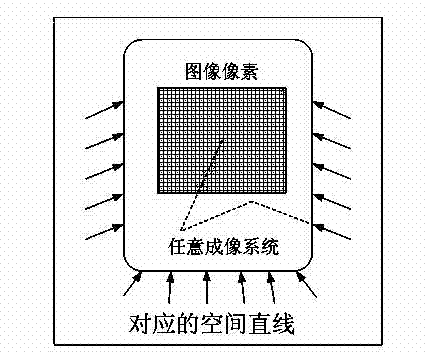

[0023] The workflow of the nanoscale three-dimensional shape measurement method based on the scanning electron microscope is as follows: use the scanning electron microscope imaging system to photograph the sample from at least two angles under the same magnification, and obtain a set of electronic images; use the digital image correlation method, For example, the Harris Detector method extracts feature point sets from multiple electronic images, and performs feature point matching to find out the corresponding points of the features; then uses the homograph matrix (Homograph) to determine the relative positional relationship of multiple images when they are taken , that is, the external parameters; finally, three-dimensional reconstruction is carried out according to the found feature corresponding points, external parameters and pre-calibrated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com