Mechanical-hydraulic bonding composite stepless speed regulating device

A stepless speed regulation, compound technology, applied in mechanical equipment, transmission devices, fluid transmission devices, etc., can solve the problems of high use and maintenance costs, loose device structure, complex overall structure, etc., and achieve long service life and structure. Reasonable, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

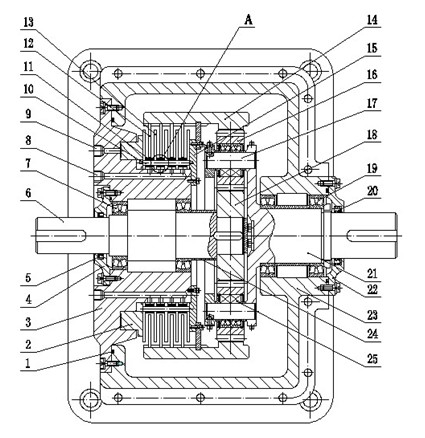

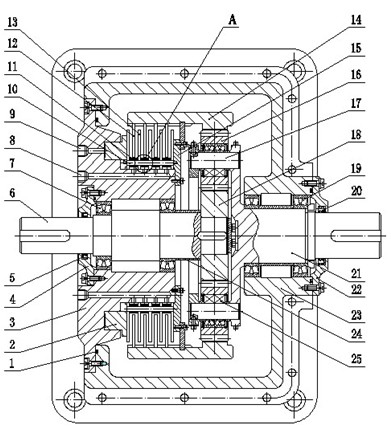

[0012] figure 1 It is an assembly diagram of a mechanical-hydraulic compound stepless speed regulation device of the present invention, which includes a piston 2, a support block 3, an input shaft 6, a pin shaft 10, a disc spring 11, an outer friction plate 12, and an inner friction plate 13. Ring gear 14, block 15, planetary gear 16, planetary shaft 17, sun gear 18, output shaft 21, housing 23 and planetary bearing 25; support block 3 is connected with housing 23 to form a closed space; input shaft 6 Installed on the support block 3 through the first bearing 7, it is provided with the first skeleton seal 5 with the input shaft end cover 4, and one end in the closed space is fixedly connected with the sun gear 18; the input shaft 6 is equipped with the first bearing 7 A shaft sleeve 24 for positioning with the sun gear 18; the output shaft 21 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com