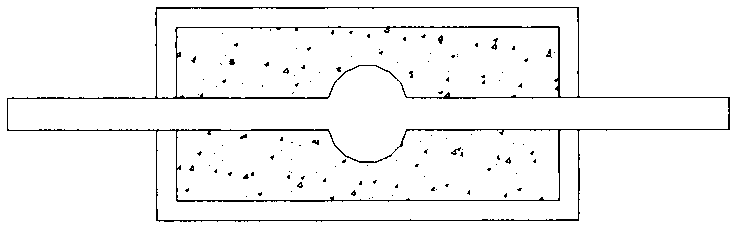

Assembled lead shear damper

A damper and assembled technology, which is applied to bridge parts, building components, bridges, etc., can solve the problems of difficult effective connection between the lead column and the upper and lower cover plates of the sliding plate, the complicated lead filling process of the closed cavity, and the complicated lead filling process. , to achieve good stability and durability, simple structure and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

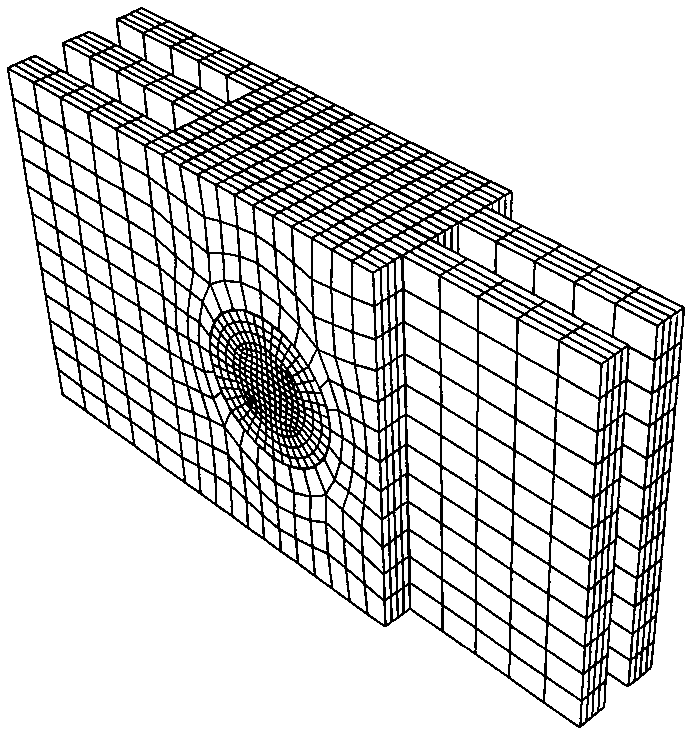

Image

Examples

Embodiment example

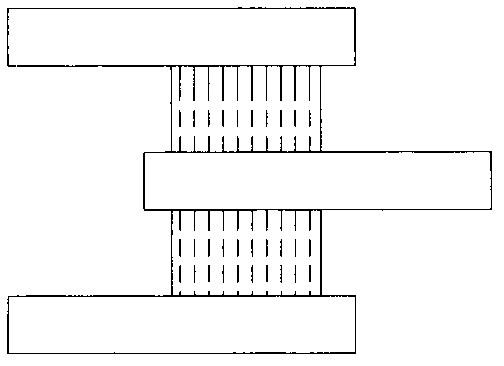

[0040] Such as Figure 19 The implementation example shown: the middle tie plate 1 and the first inner layer tie plate and the second inner layer tie plate can be connected and fixed by high-strength bolts 7; the end connecting plate 4 is connected to the first inner layer tie plate and the second inner layer tie plate High-strength bolts 7 can also be used to connect and fix; the gap between the first outer pull plate 21, the second outer pull plate 22 and the middle pull plate 1 is filled with a lining plate 5, and the high-strength bolts 7 pass through the first outer pull plate 21, the second Two outer tie plates 22, the middle tie plate 1 and the liner plate 5 are fastened with a certain prestress. Connecting pin (8) also can adopt high-strength bolt, applies certain prestress to 3 inner layer pull plates, the first outer pull plate 21 and the second outer pull plate 22, to improve friction effect, strengthen energy dissipation capacity.

[0041]The ends of the central p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com