Spiral joints, main joint segment, spiral material division device for paver and paver

A technology of spiral distribution and spiral joints, applied in the field of spiral distribution device and paver, can solve the problems of 12-weight lengthened shaft, unfavorable quick disassembly and assembly, large workload, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

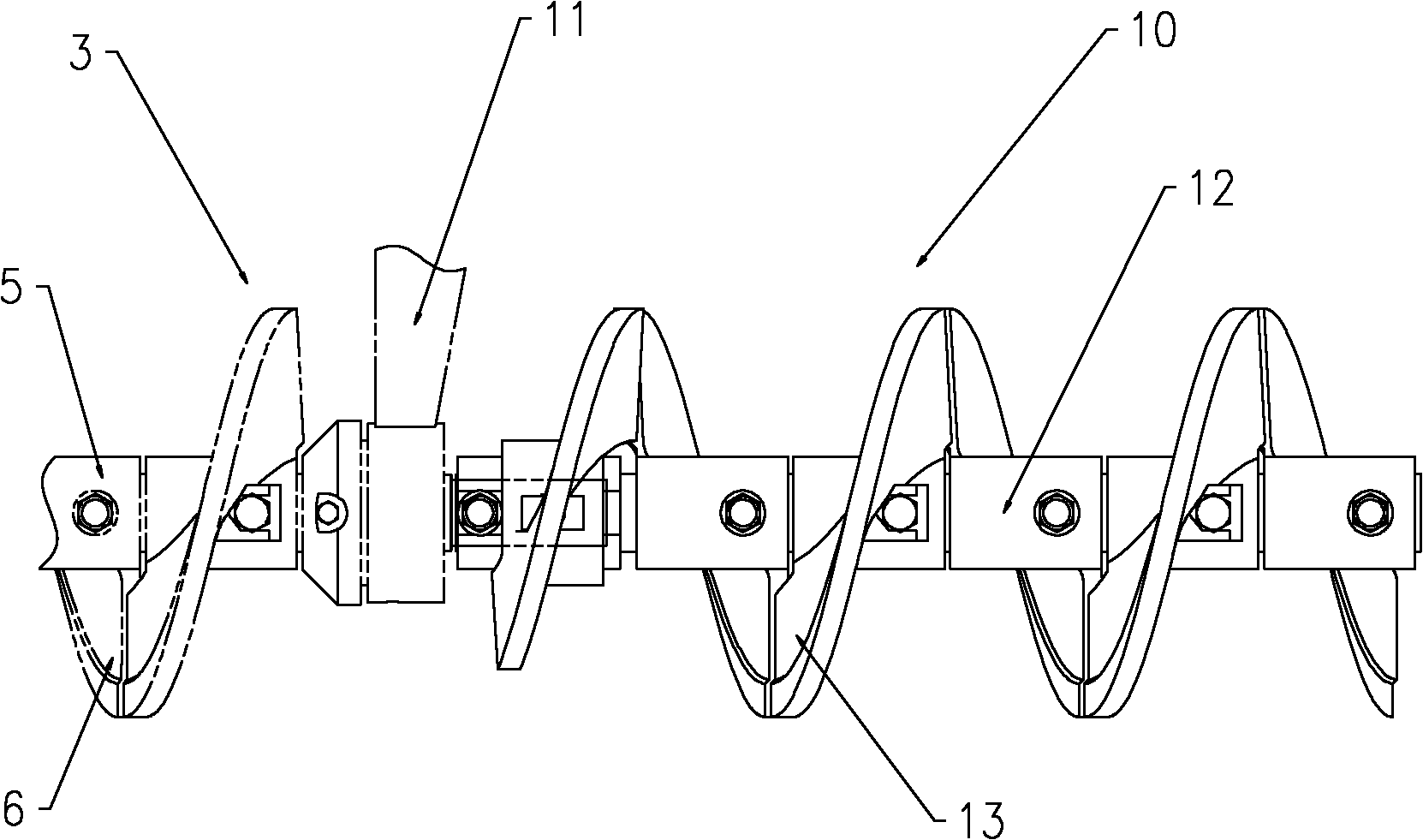

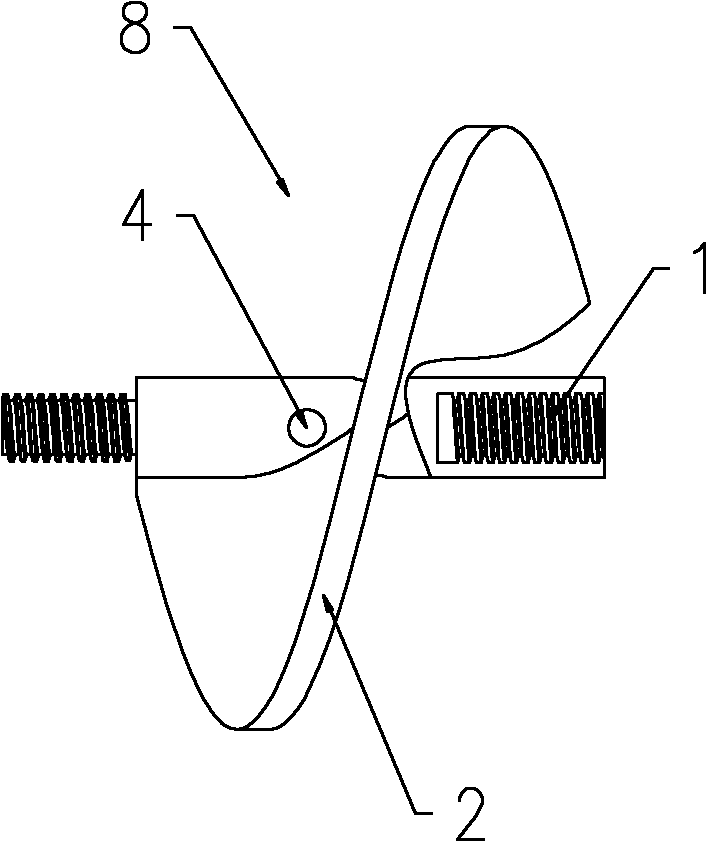

[0037] According to a preferred embodiment of the present invention, the helical direction of the helical blade 2 is opposite to the helical direction of the thread on the one end of the shaft 1 . In this way, when the paver is working, the blades of the spiral material distribution device will convey the material laterally along the entire paving width of the paver to both sides, and the reaction force of the material to the spiral blade 2 will tighten the screw joint, thus realizing Automatic anti-loosening function.

[0038] According to another embodiment of the present invention, the other end of the shaft 1 is also provided with threads. In this way, the threads on the two ends of the shaft 1 can be respectively connected with the main shaft of the main section and another spiral section or respectively connected with two spiral sections, so that the length of the screw distributing device can be adjusted conveniently and quickly. The needs of different paving condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com