Water purification system and water purification method for inclined tube floating sedimentation tank

A water purification system and inclined tube sedimentation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of improving the air flotation effect, avoiding running alum, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

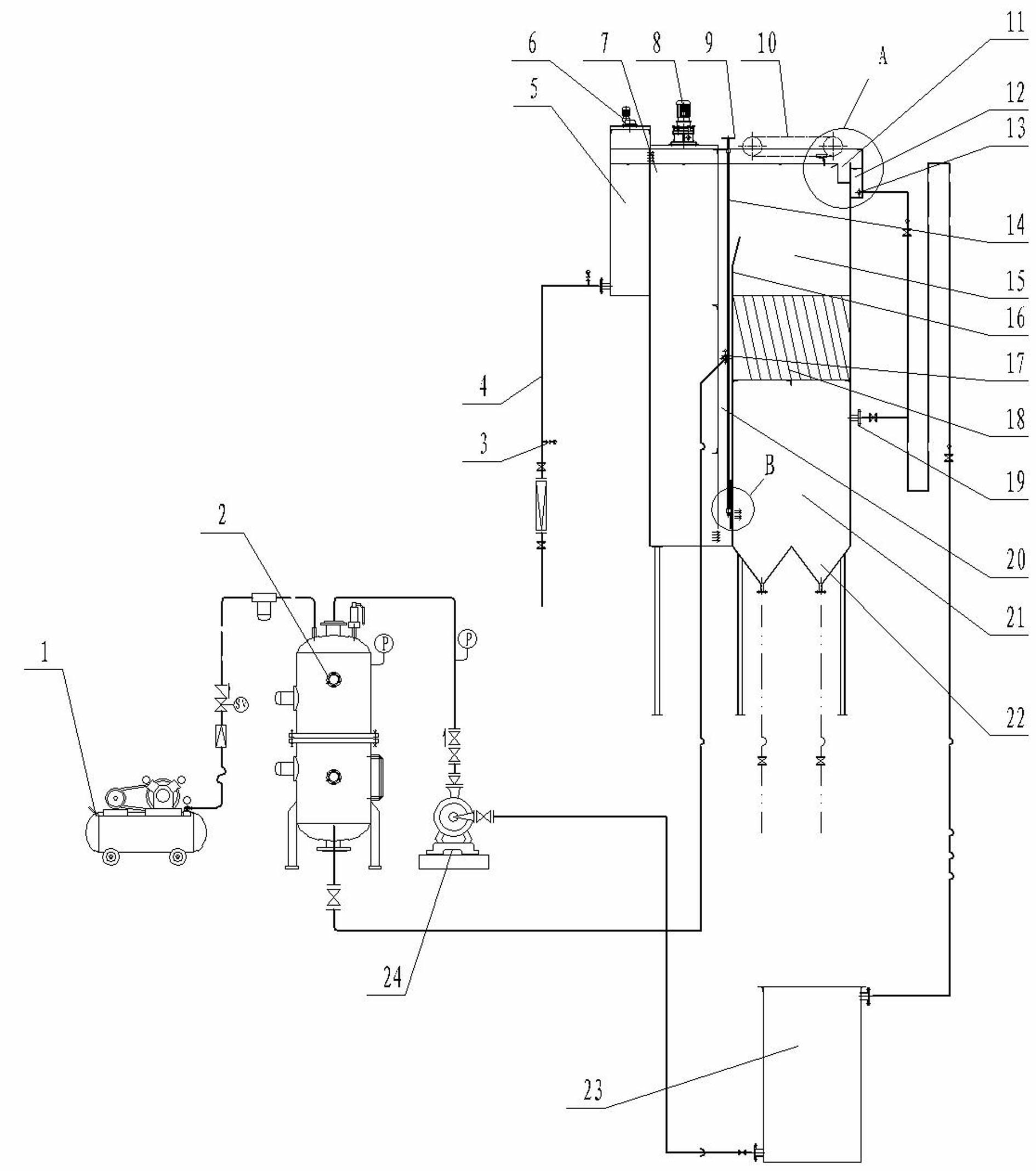

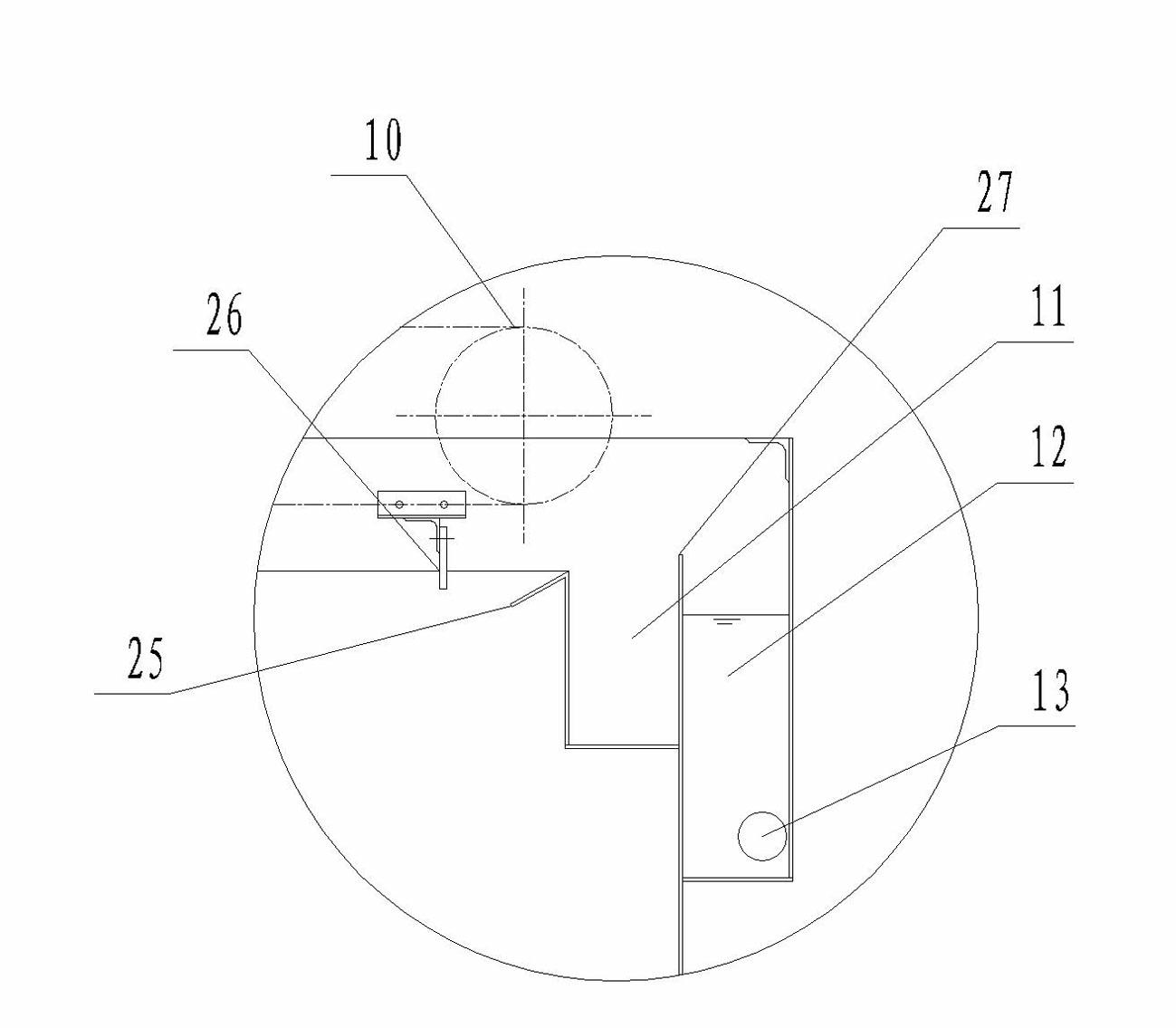

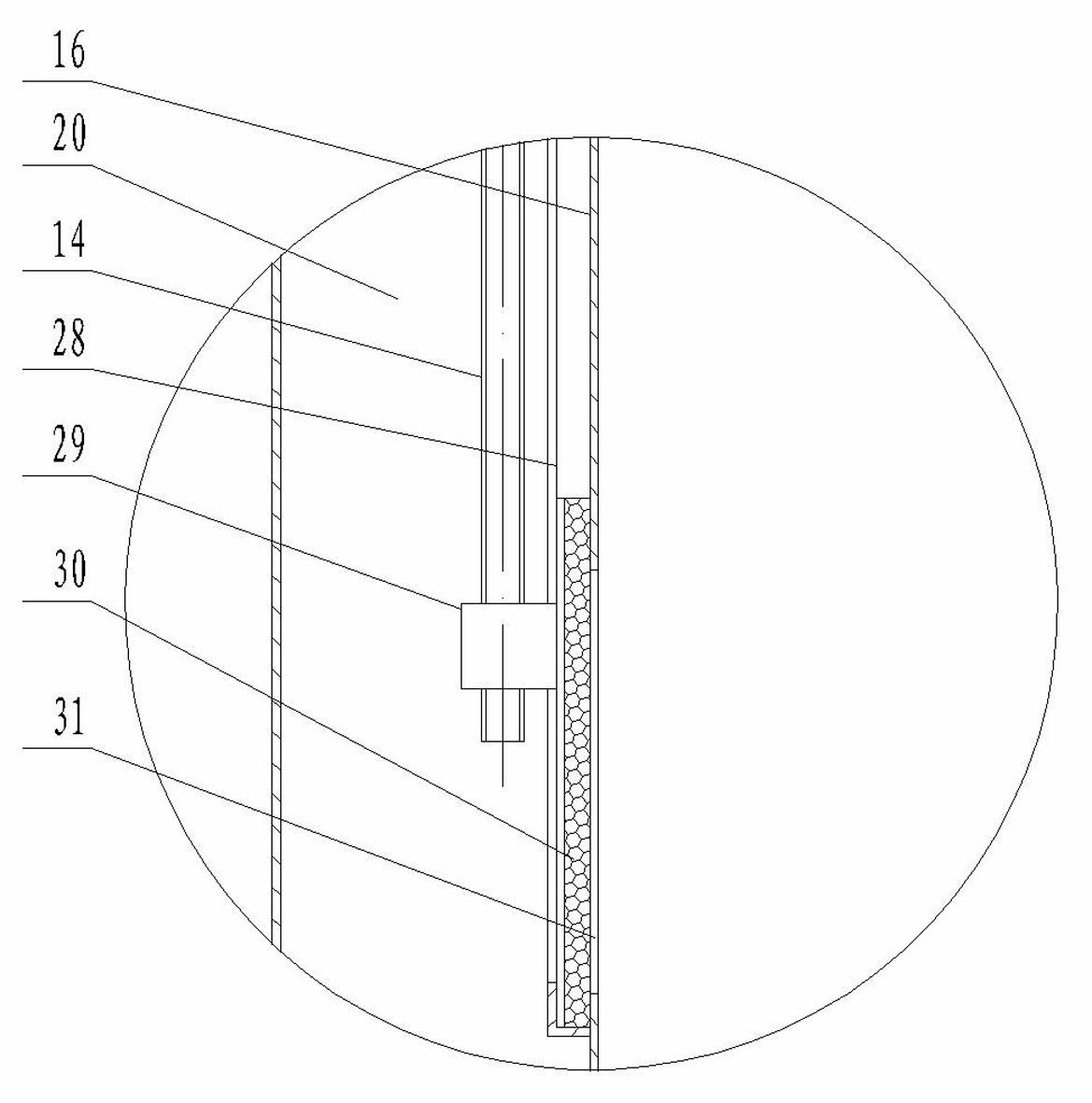

[0016] Such as figure 1 A kind of floating sink water purification system shown, it comprises floating sink and dissolved air generator, floating sink includes mixing tank 5, flocculation chamber 7, air flotation contact chamber 20, air flotation separation chamber 15, inclined tube settling area 18 and In the sedimentation water distribution area 21, the mixing tank 5 is equipped with a stirring device I6, the stirring device I6 adopts a paddle agitator, and the flocculation chamber 7 is equipped with a stirring device II8, and the agitating device II8 adopts a paddle agitator. Paddles with different radii are installed at different heights of the stirring shaft, and the stirring shaft rotating at a constant speed drives the paddles with different radii, so that the stirring intensity of the water flow at different heights in the flocculation tank is different, and the flocculation effect is better. The mixing tank 5, the flocculation chamber 7 and the air flotation separatio...

specific Embodiment 2

[0021] The inclined tube floating-sinking tank water purification system of this specific embodiment is basically the same as the inclined tube floating-sinking tank water purification system of the specific embodiment 1, except for the following special limitations: the aspect ratio of the air flotation contact chamber is 16:3, the flocculation chamber, The air flotation contact chamber and the air flotation separation chamber have the same length, and the width ratio of the flocculation chamber, the air flotation contact chamber and the air flotation separation chamber is 4.7:1:8.

[0022] The difference between this water purification method and the specific embodiment one water purification method is that the reflux ratio of dissolved air water is 8%.

specific Embodiment 3

[0023] The water purification system of the inclined tube floating sink in this specific embodiment is the same as that of the inclined tube floating sink in the second embodiment.

[0024] The difference between this water purification method and the water purification method in Embodiment 2 is that the reflux ratio of dissolved air water is 8.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com