Machine tool

A technology of machine tools and racks, applied in the direction of metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., to achieve the effect of accuracy improvement, improved processing accuracy and dimensional stability, and high feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

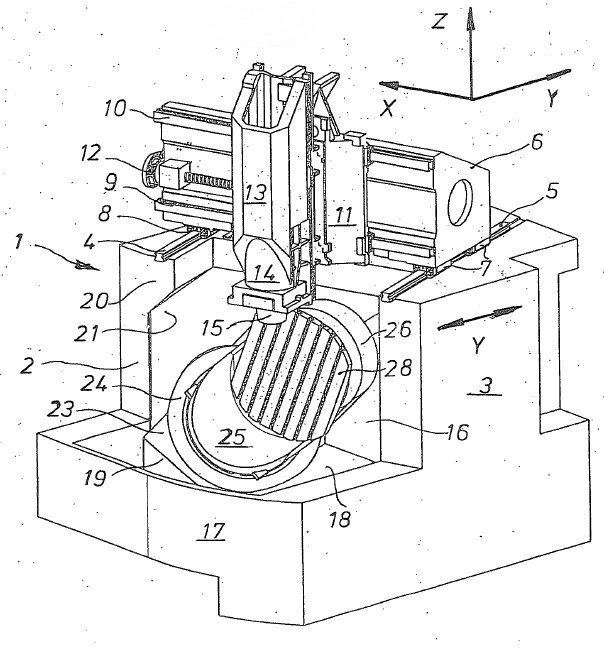

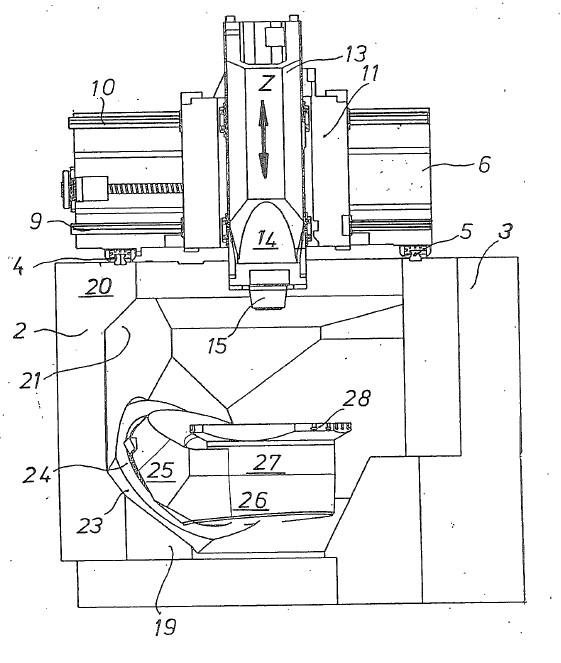

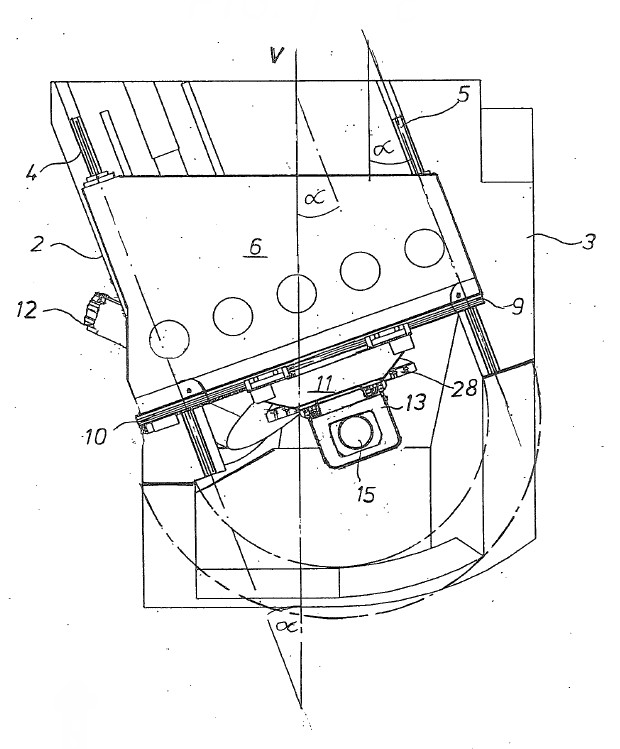

[0028] , the machine tool shown in the various views of FIG. 1 is implemented in a gantry configuration and includes a program control unit (not shown) as well as eg a tool changer and other additional units. The machine frame 1 is preferably realized in one-piece construction in order to achieve the required high rigidity. The two side walls 2 , 3 extend parallel to the Y coordinate axis and carry on their top sides horizontal guide rails 4 , 5 as part of a linear guide for the transverse slide 6 , which can be accessed via guide shoes 7 , 8 The transverse slide 6 is guided in a displaced manner on the guide rails 4 , 5 . An electric motor comprising a shaft drive or a linear motor is used as the drive for the displacement movement of the transverse slide 6 forming a crosshead spanning the two side walls 2 , 3 . On the face of the transverse slide 6 , the slide 11 is guided in two vertically spaced guide rails 9 , 10 by means of a motorized drive unit 12 so as to be displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com