Welding fixture

A technology for welding fixtures and bottom plates, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large position accuracy error, difficulty in improving product grades, large workpiece error, etc., and achieve stable positioning reference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

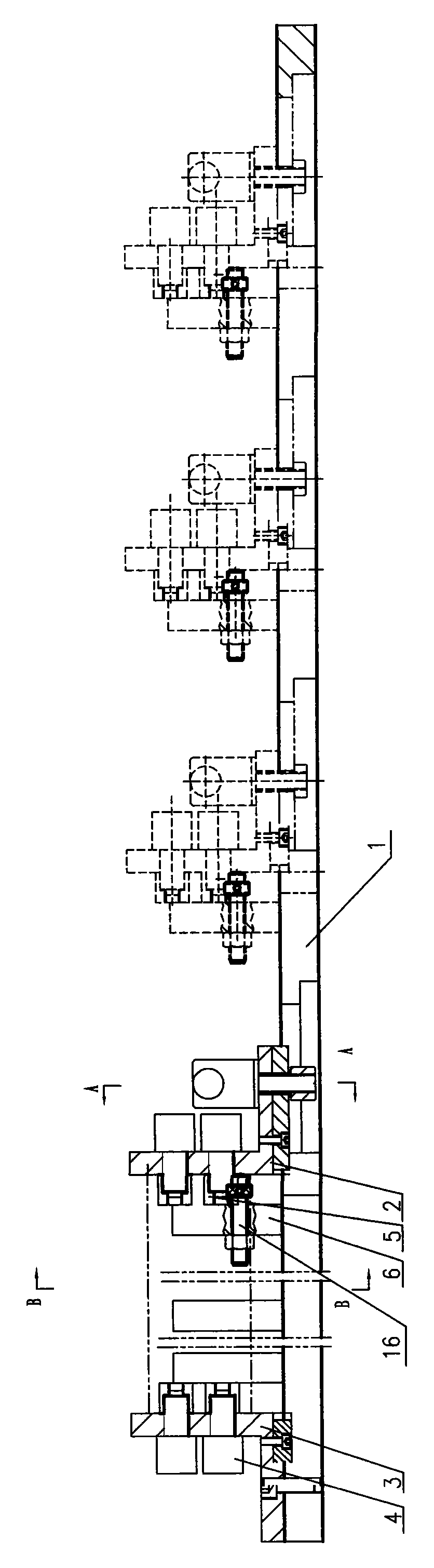

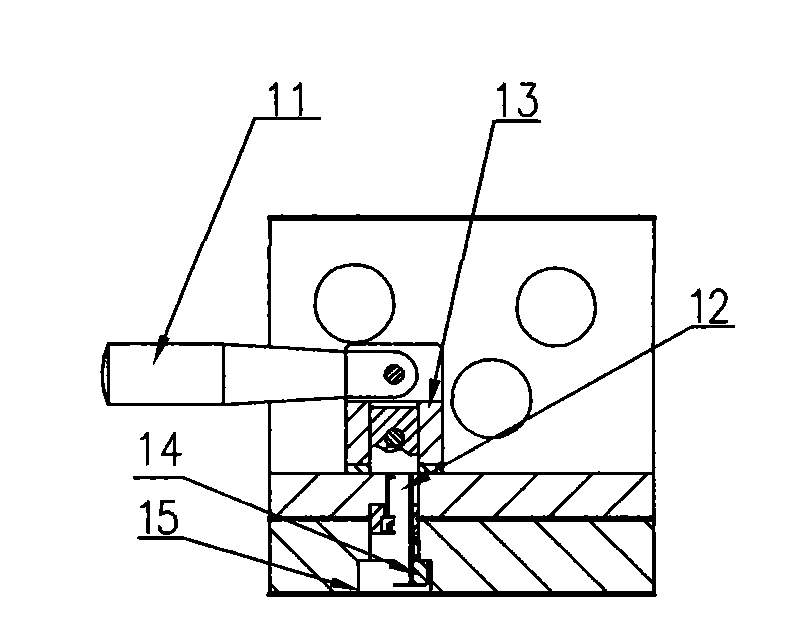

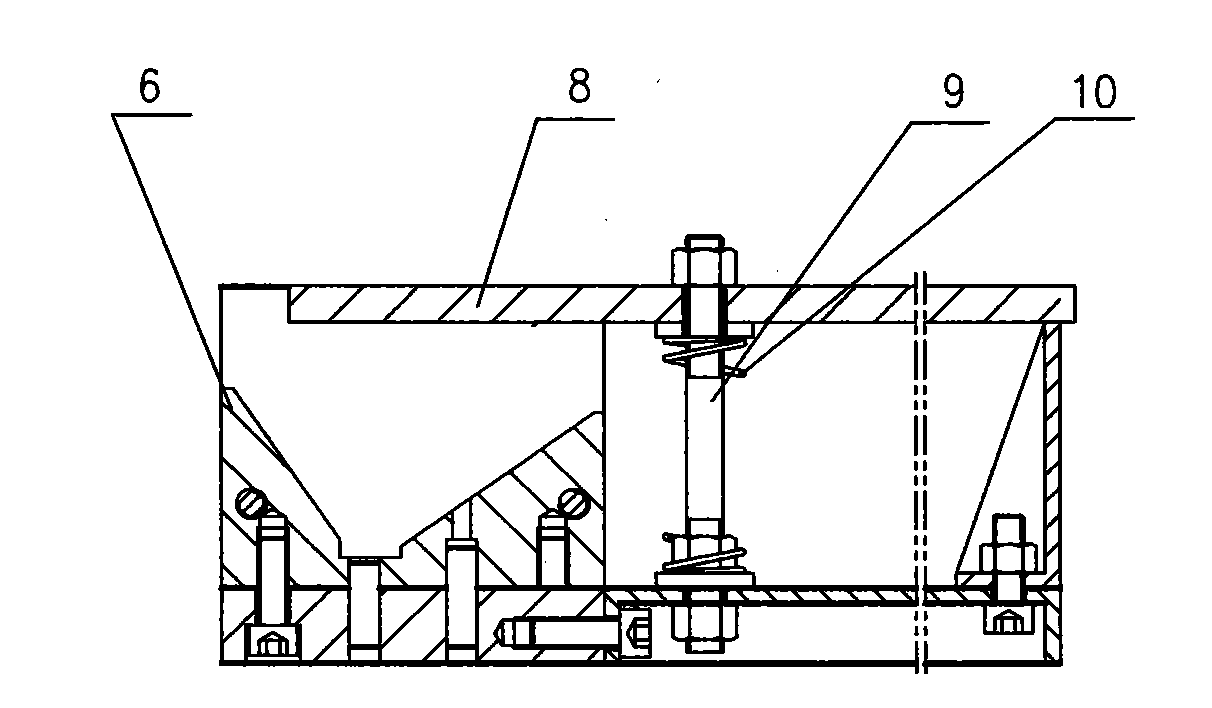

[0012] Embodiment 1, a kind of welding fixture, with reference to figure 1 , figure 2 , image 3 One end of the bottom plate 1 is fixed with a fixed curved plate 3, and the bottom plate 1 is provided with a movable curved plate 2 that can be moved and positioned along the bottom plate 1. The facades of the fixed curved plate 3 and the movable curved plate 2 are opposite, and the fixed curved plate 3 and the positioning screw sleeve 5 connected to the workpiece by the movable positioning pin 4 on the facade of the mobile bending plate 2, the thread at the end of the movable positioning pin 4 is connected with the internal thread of the positioning screw sleeve 5, and the positioning pin 4 can be positioned by rotating the movable positioning pin 4. The screw sleeve 5 is fixed on the elevation of the movable curved plate 2 and the fixed curved plate 3, and V-shaped blocks 6 are arranged at intervals on the bottom plate 1, and positioning screws 16 are housed on the V-shaped bl...

Embodiment 2

[0013] Embodiment 2, a kind of welding fixture, refer to figure 1 , figure 2 , figure 2 , is on the basis of embodiment 1, the inboard of the two arms of V-shaped block 6 is provided with supporting block 7, and supporting block 7 is positioned on the V-shaped block 7 by bolt activity, and other is identical with embodiment 1.

[0014] When using the present invention, the workpiece is first placed on the V-shaped block 6, and then the movable curved plate 2 is pushed to lean against the positioning surface of the positioning screw 16, and the handle 11 is turned to fasten the movable curved plate 2 to realize length positioning, and then the positioning The screw sleeve 5 is installed on the positioning pin 4 and tightened, and then the pressure plate 8 is turned to the clamping position to press the workpiece to be welded; when unloading, just loosen the nut of the pressure plate 8, and the spring 10 will bounce it up, and loosen the positioning pin Unclamp the handle 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com