Connection method for split wheel-installed brake disk

A connection method and brake disc technology, applied in the direction of the brake disc, brake type, brake components, etc., can solve the problems of inconvenient operation, long cycle, increased labor and material cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

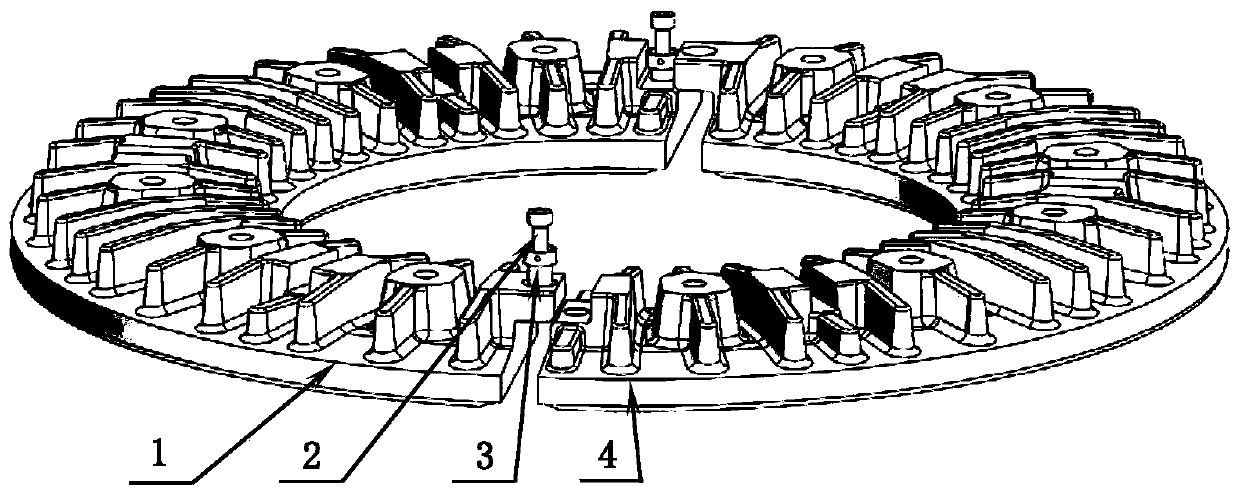

[0022] A method for connecting a split wheel-mounted brake disc, comprising a disc body A 1 and a disc body B 4, a positioning sleeve and a hexagon socket head screw 2, the disc body A 1 and the disc body B 4 have exactly the same structure, and the disc body A 1 and the back side of the disk body B 4 are slat-shaped cooling ribs, such as figure 1 shown.

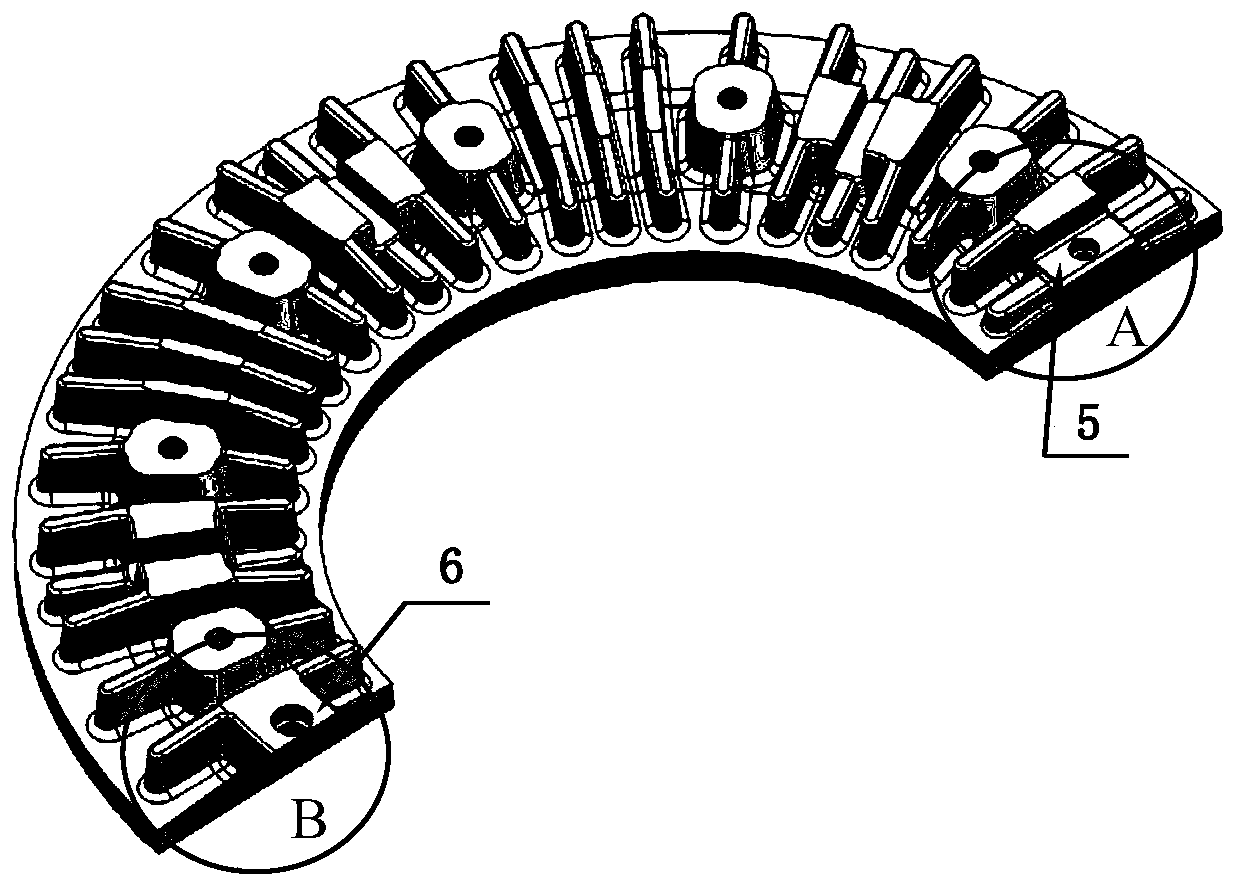

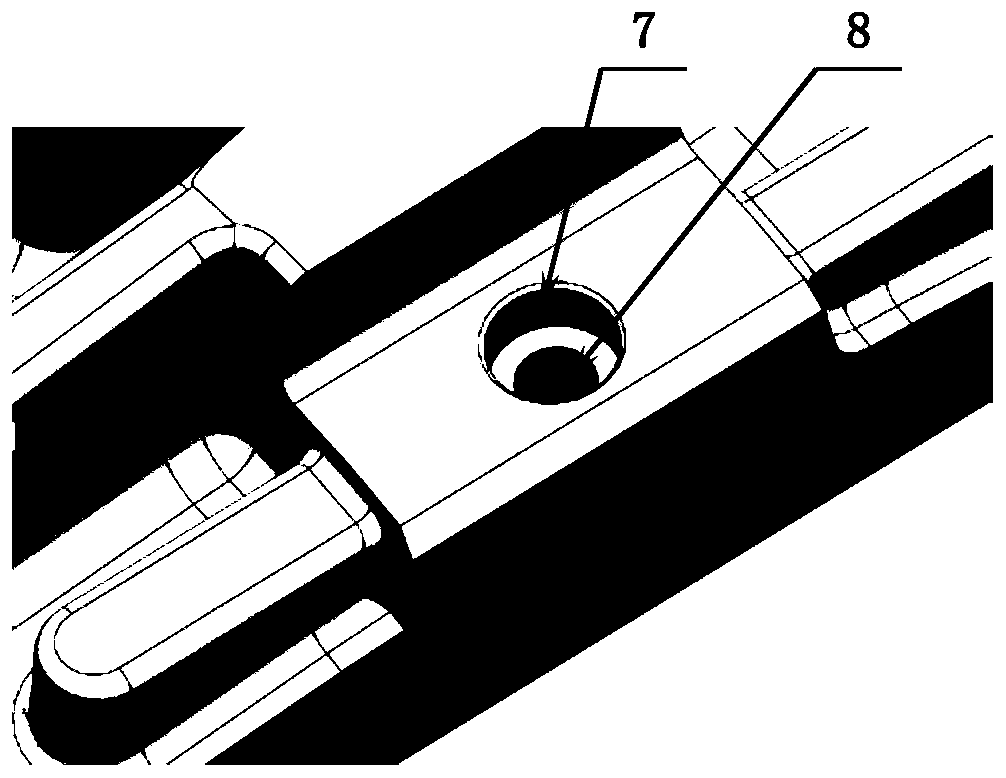

[0023] The two ends of the disc body A 1 and the disc body B 4 are respectively arranged with grooves 5 and flanges 6, the grooves 5 are provided with positioning holes A7 and threaded holes 8, and the flanges are provided with counterbores 10 and positioning holes B9, like figure 2 , image 3 , Figure 4 , Figure 5 shown.

[0024] The positioning sleeve 3 passes through the flange 6 and the groove 5 accordingly to realize the radial and circumferential positioning of the disk body A1 and the disk body B4, such as figure 1 As shown, the hexagon socket head cap screw 2 is tightened through the positioning sleeve 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com