Gas-filling system having a residual-gas recovery device, and residual-gas recovery method

A gas filling system and natural gas technology, applied in the field of gas filling system to maximize gas filling efficiency and minimize capital flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

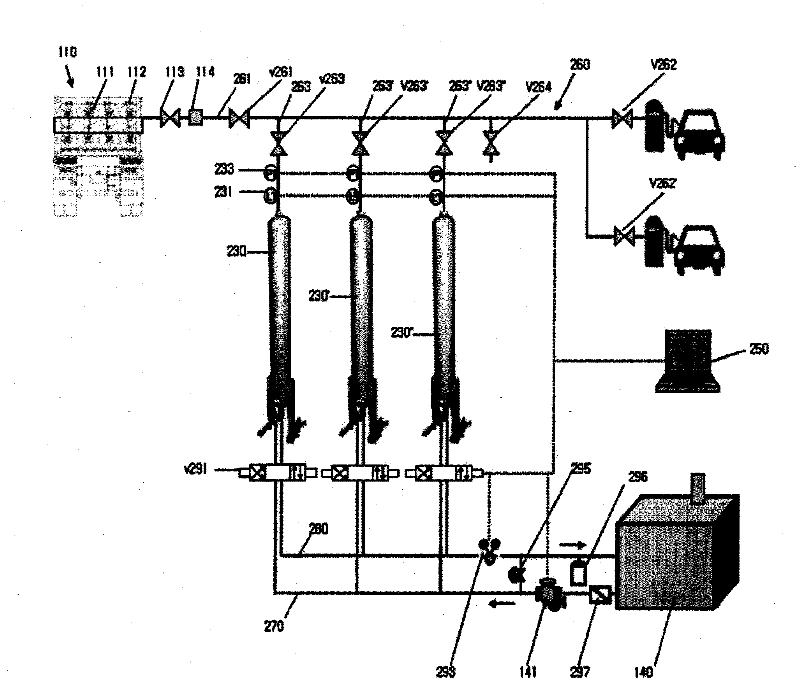

[0019] Such as figure 1 As shown, the specific example of the inflation system of the device for recovering residual natural gas includes: a long tube trailer 110, a gas vending machine 120, a compression tank 130, an oil storage tank 140, a controller 150, a natural gas supply pipe 160, an oil delivery pipe 170, and an oil return pipe 180, Pressure sensor 133, oil level sensor 131, pump 141 and multiple safety valves v161, v162, v163, v171, v181.

[0020] First, the gas-filled long-pipe trailer 110 is used as a mobile tool, and its multiple high-pressure natural gas containers 111 are connected to each other by gas pipes 112 and installed on guide rails, making the movement of compressed natural gas possible.

[0021] In order to discharge the compressed natural gas stored in the gas pipe 112, a discharge port 114 connected to a gas pipe safety valve 113, a gas pipe controller (not shown) and an external natural gas supply pipe 160 is installed.

[0022] The following gas ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com