Method and device for determining fault elimination based on operation and maintenance (OAM)

A technology for determining faults and faults, applied in the field of data communication, which can solve problems such as increasing physical storage space and limiting the number of OAM sessions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

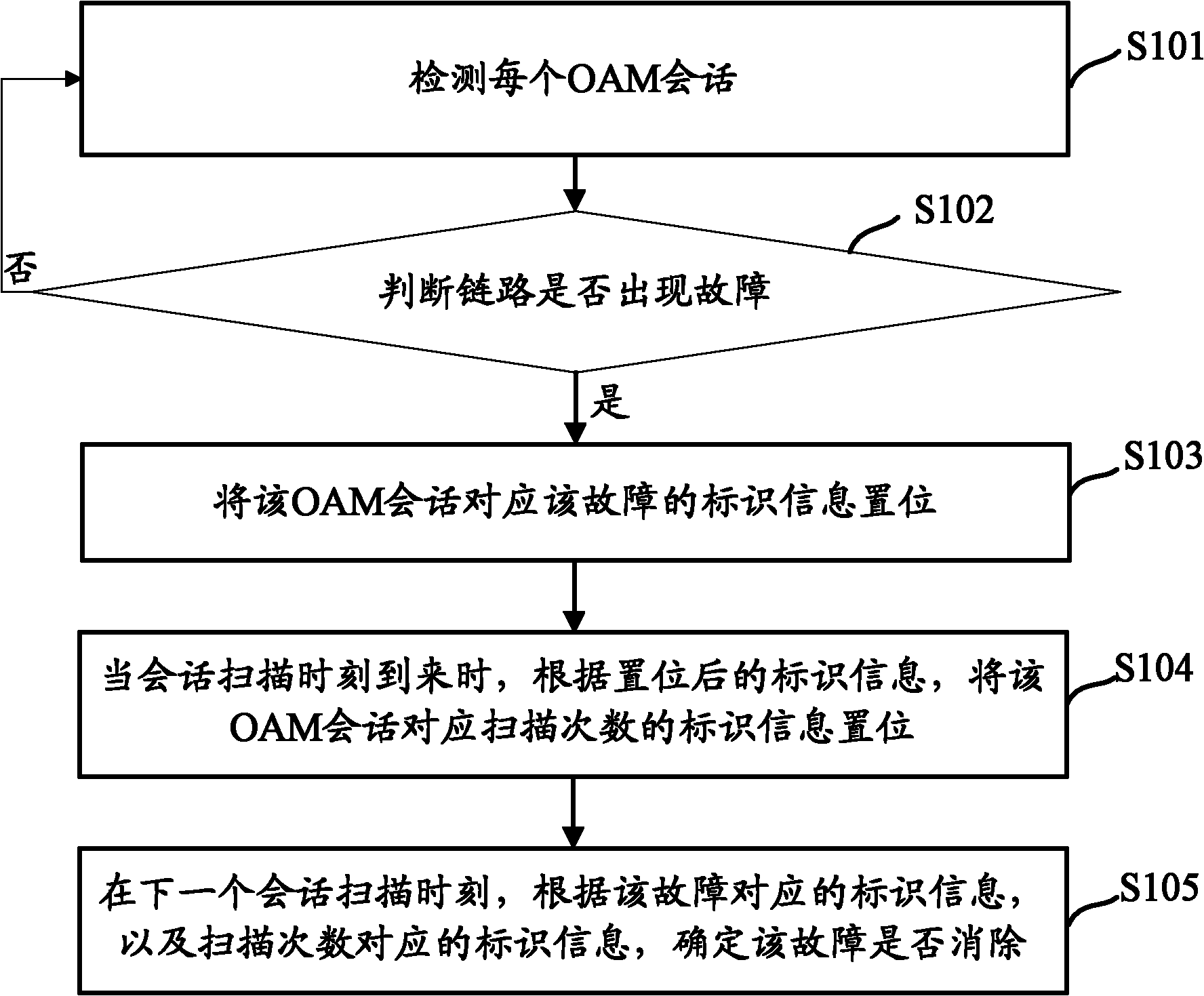

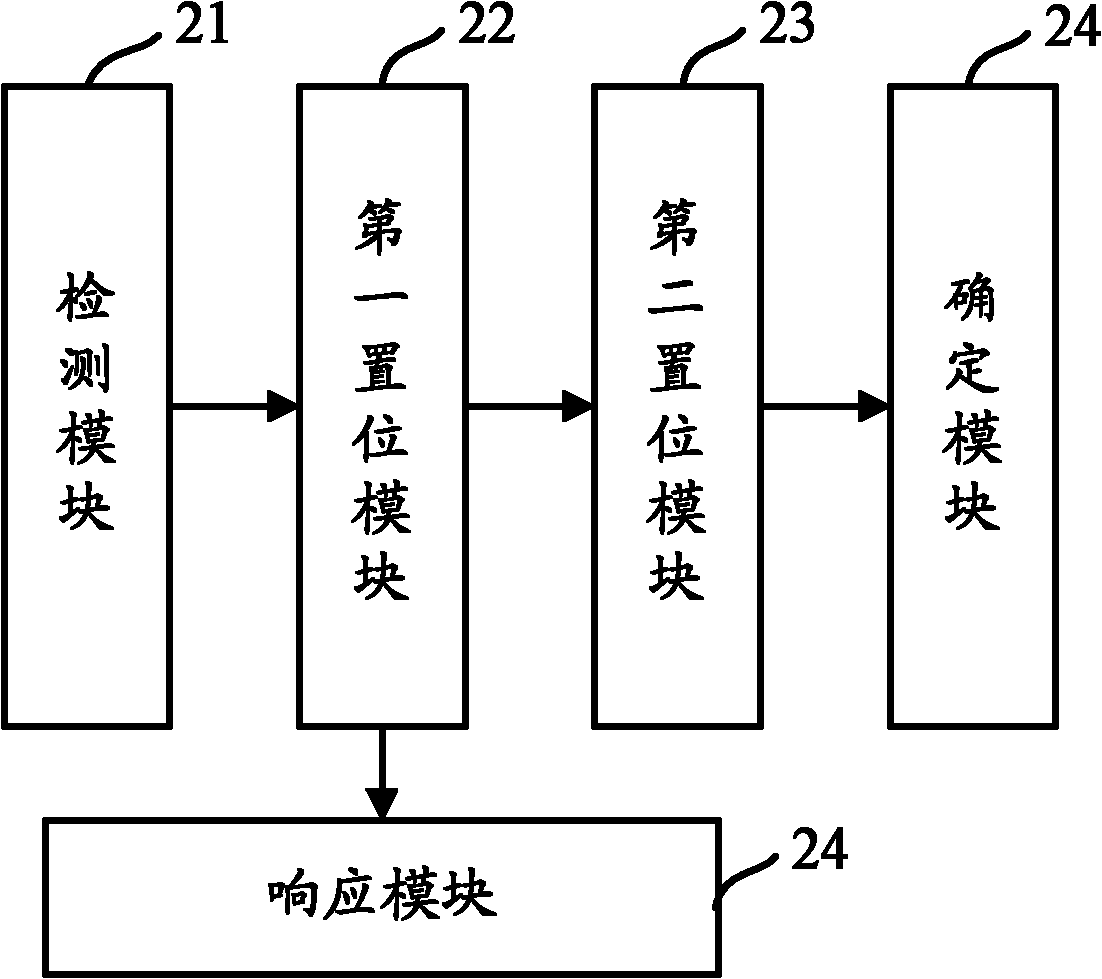

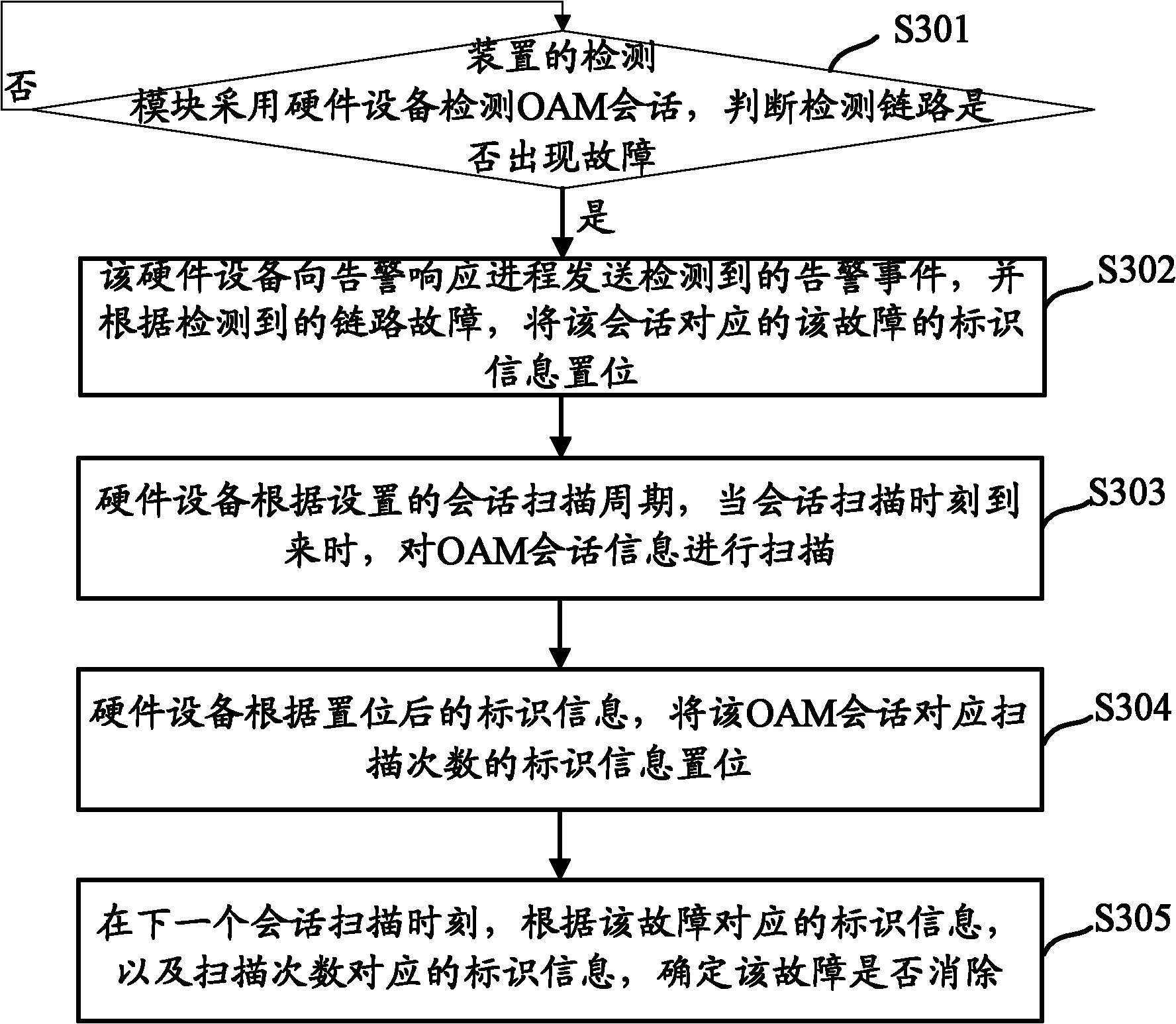

[0022] In order to reduce the dependence on hardware timers, reduce the storage space occupied by table entries, and improve the flexibility of the system, the embodiments of the present invention provide a method and device for determining fault elimination based on the OAM protocol. At the time of session scanning, the identification information corresponding to the fault and the identification information corresponding to the number of scans are detected to determine whether the fault is eliminated. There is no need to use the hardware timer to determine whether the fault is eliminated, thereby reducing the storage space occupied by the hardware timer index entry. There is no need to set a corresponding number of timers for each OAM session, so the number of OAM sessions can be adjusted arbitrarily, which improves the flexibility of the system.

[0023] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com