Device for testing zero distortion of carbon fiber member

A testing device and carbon fiber technology, which can be used in measurement devices, electrical devices, optical devices, etc., can solve the problem of low thermal expansion coefficient accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

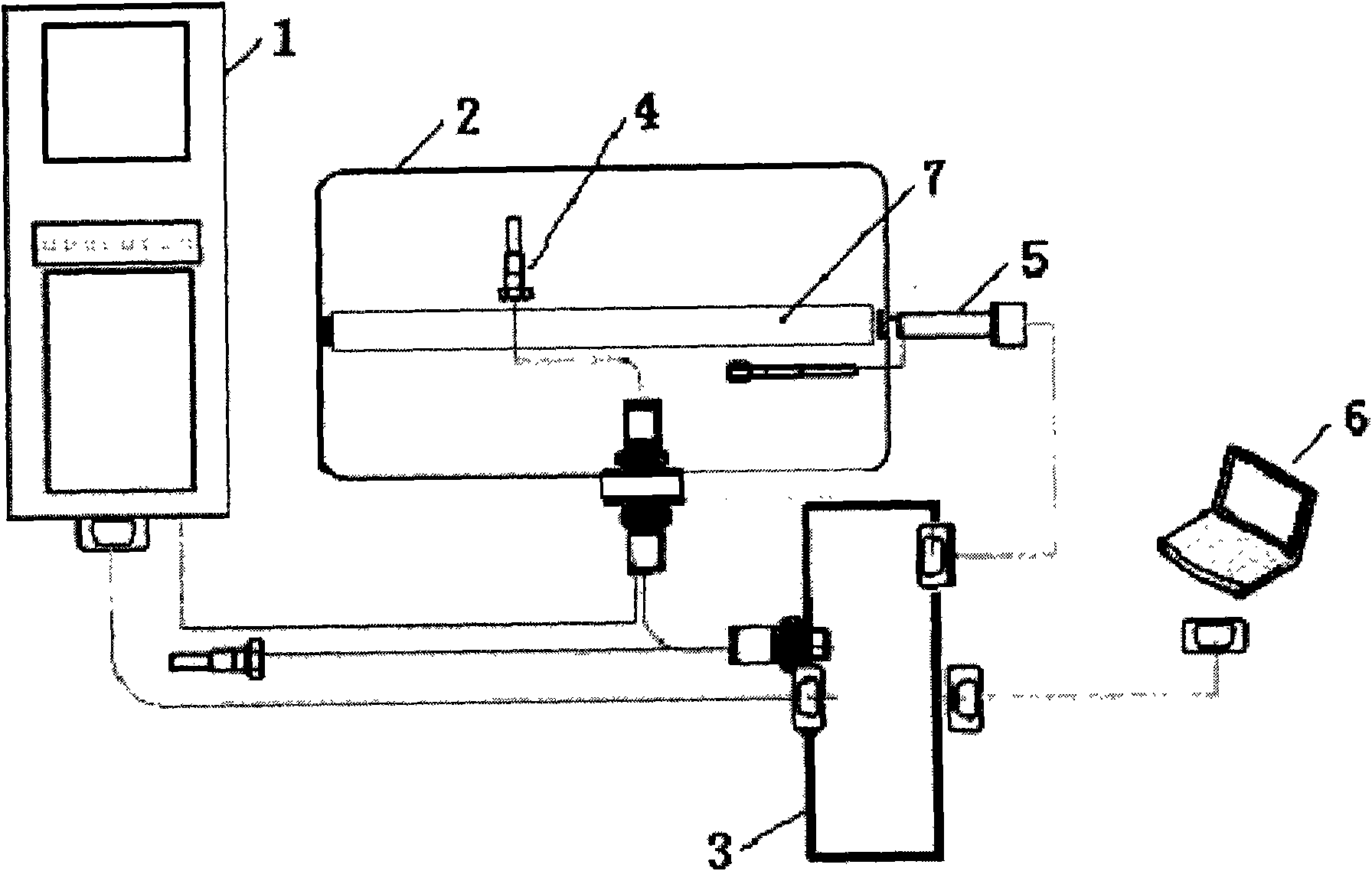

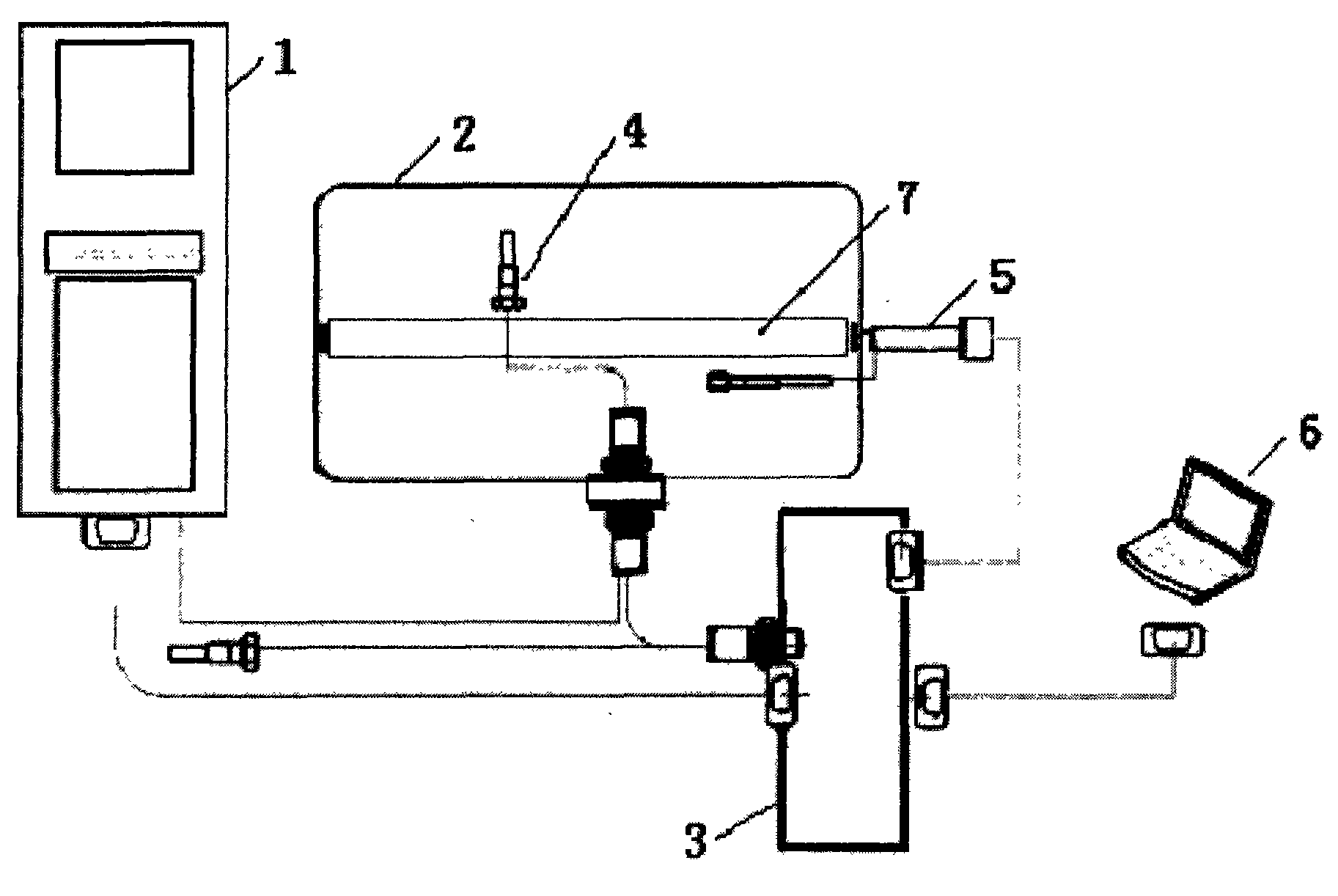

[0015] The accompanying drawing is a schematic structural diagram of the carbon fiber component zero deformation testing device of the present invention, as shown in the embodiment of the accompanying drawing, the device includes: a high and low temperature control cabinet [1], a high and low temperature test box [2], a measurement and control system control box [3] ], temperature sensor [4], MTI2000 optical fiber displacement sensor [5], computer control and analysis system [6] and carbon fiber components [7].

[0016] The above-mentioned carbon fiber component [7] is put into the high and low temperature test chamber [2], one end is fixed, and the other end is movable, and the extension of the movable end is measured by the MTI2000 optical fiber displacement sensor [5]. The optical fiber displacement sensor [5] is a non-contact type, and the displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com