Concrete spreader and spreading method thereof

A distributing machine and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problem of limited distribution range, achieve the effect of no dead angle, easy maintenance, and avoid overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below through specific embodiments.

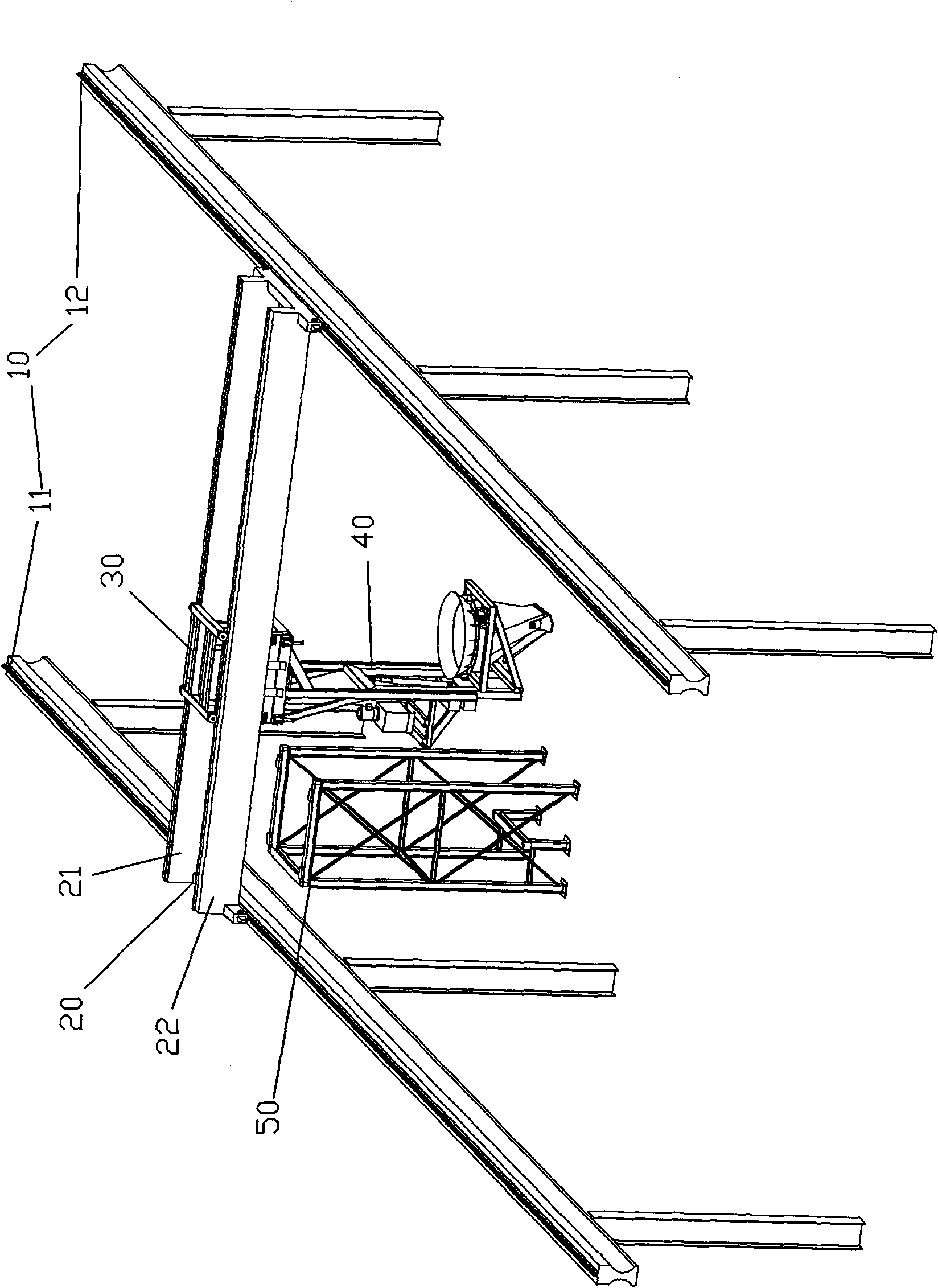

[0037] Reference figure 1 , A concrete distributor of the present invention includes a main track unit 10, a large crane 20, a small crane 30, a main machine 40 and an overhaul platform 50, a hydraulic control system and an electrical control system.

[0038] Reference figure 1 , The main rail unit 10 is composed of two main rails 11, 12 arranged longitudinally parallel to each other, and the main rails 11, 12 are at a certain distance from the ground.

[0039] Reference figure 1 , The big crane 20 is erected on the main track unit 10, including two parallel and laterally arranged secondary tracks 21, 22; both ends of the big crane 20 are equipped with self-propelled gear trains, which can be installed on the main track unit 10 according to instructions Longitudinal reciprocating motion or parking.

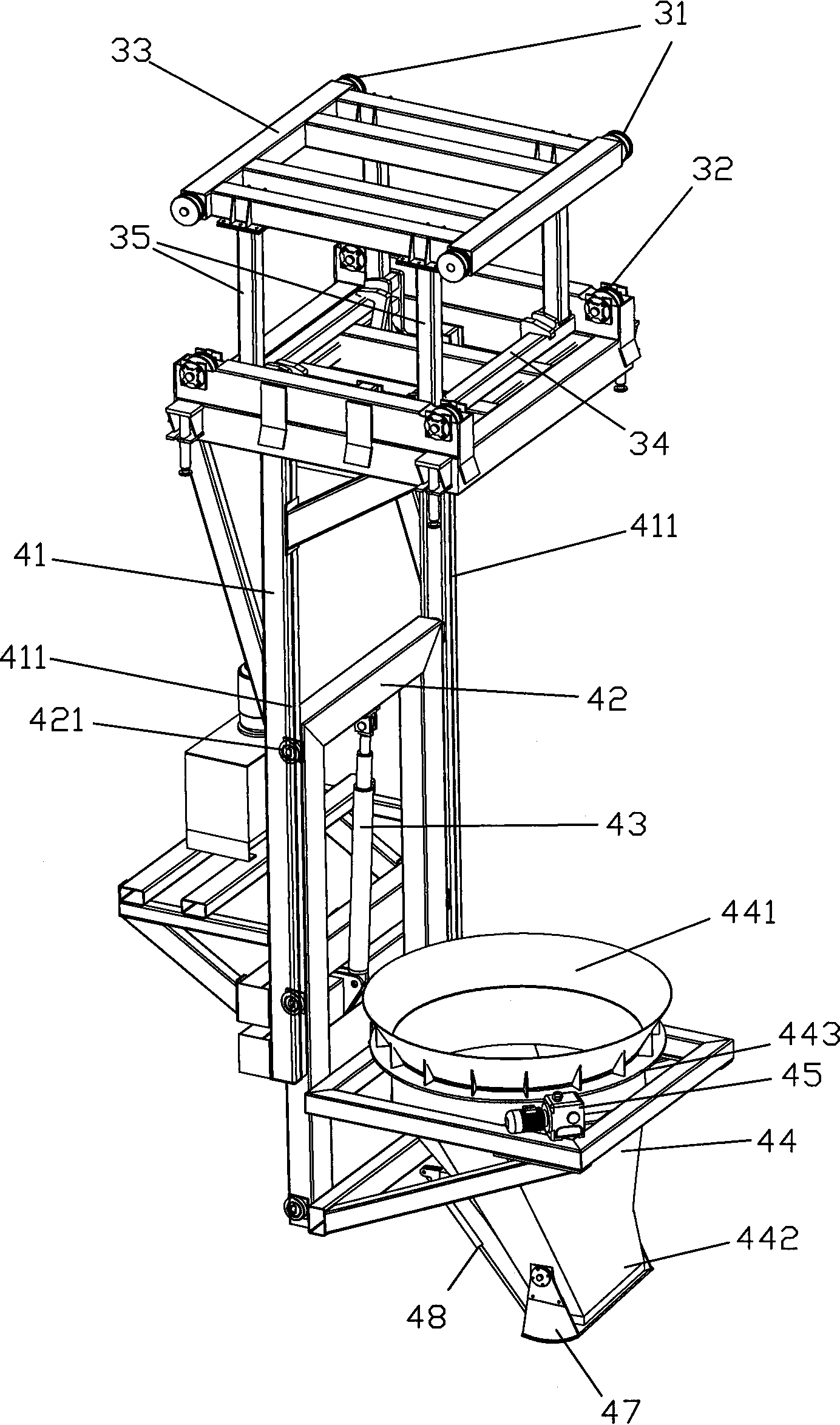

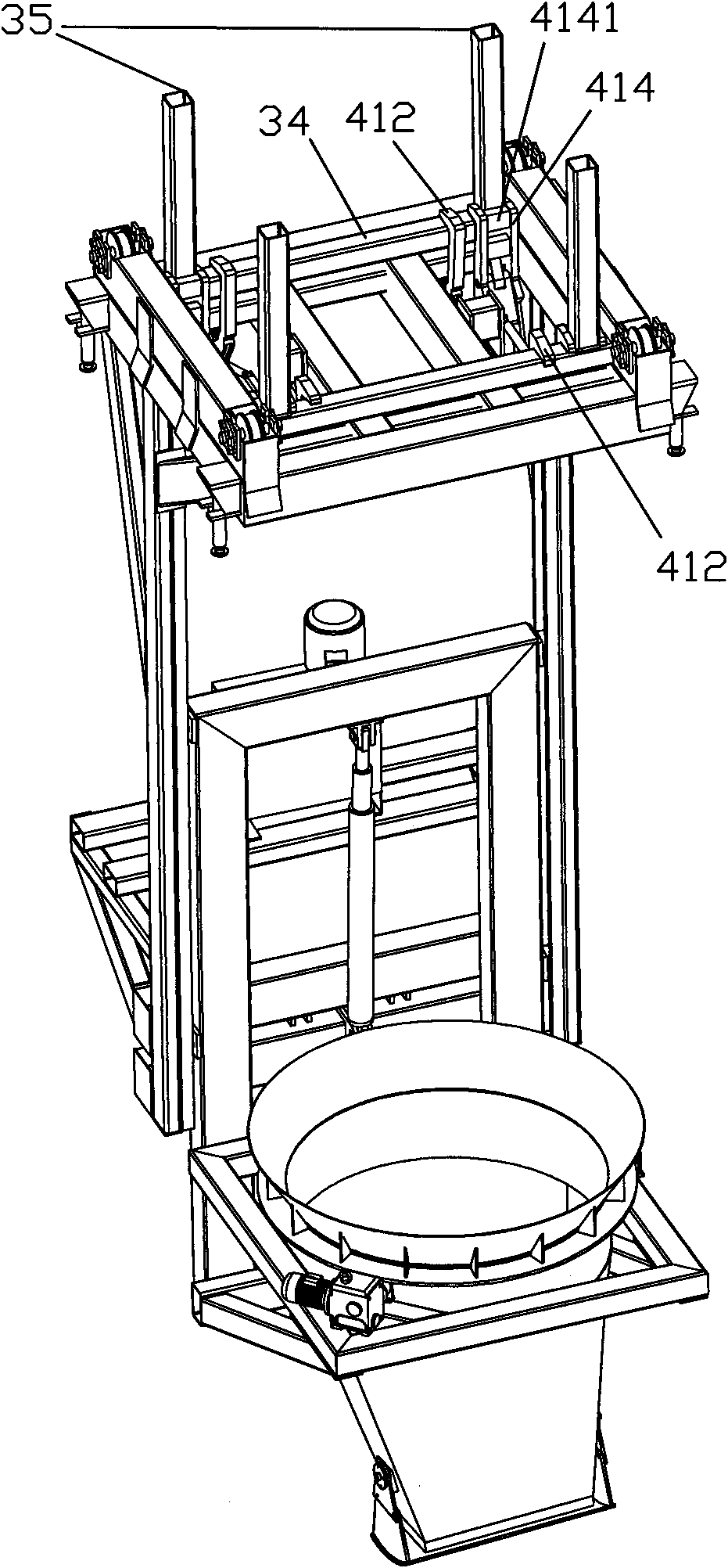

[0040] Reference figure 1 with figure 2 , The trolley 30 is erected on the trolley 20, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com