Concentration method for floatation tailings and concentration device

A technology of flotation tailings and tailings, which is applied in the directions of dehydration/drying/thickened sludge treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of unstable washing water concentration, dosing method, and dosing point layout. Basis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: Taking the concentration of flotation tailings in Fangezhuang Coal Washery as an example, the concentration of flotation tailings in Fangezhuang Coal Washery is processed by two ?45 thickeners.

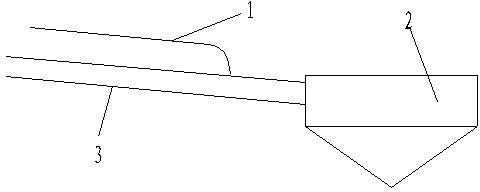

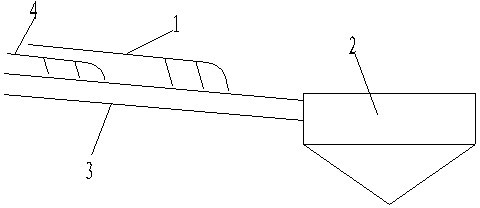

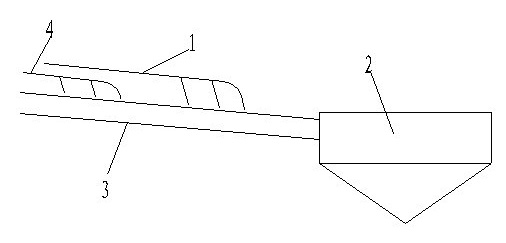

[0023] figure 1 As shown, the original thickening device is only provided with a flocculant dosing pipe 1 on the feeding pipe 3 of the tailing coal thickener 2; only flocculant can be added, which is single-point dosing. After the original thickener was put into production, due to the increase in the content of coal slime, it could not settle in time in the tailing coal thickener, and the overflow water concentration of the tailing coal thickener was high, resulting in the abnormal operation of the slime water system. After analysis, the disadvantage of the original concentration device is single-point dosing. When the coal quality changes, such as the increase of coal slime content or argillaceous shale, the quality of washing water cannot be guaranteed, resulting in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com