Cooling fan and rotor thereof

A heat dissipation fan and rotor technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., can solve problems such as loud noise and limited fan heat dissipation performance, and achieve increased air volume and supplementary Pressure, swirl reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

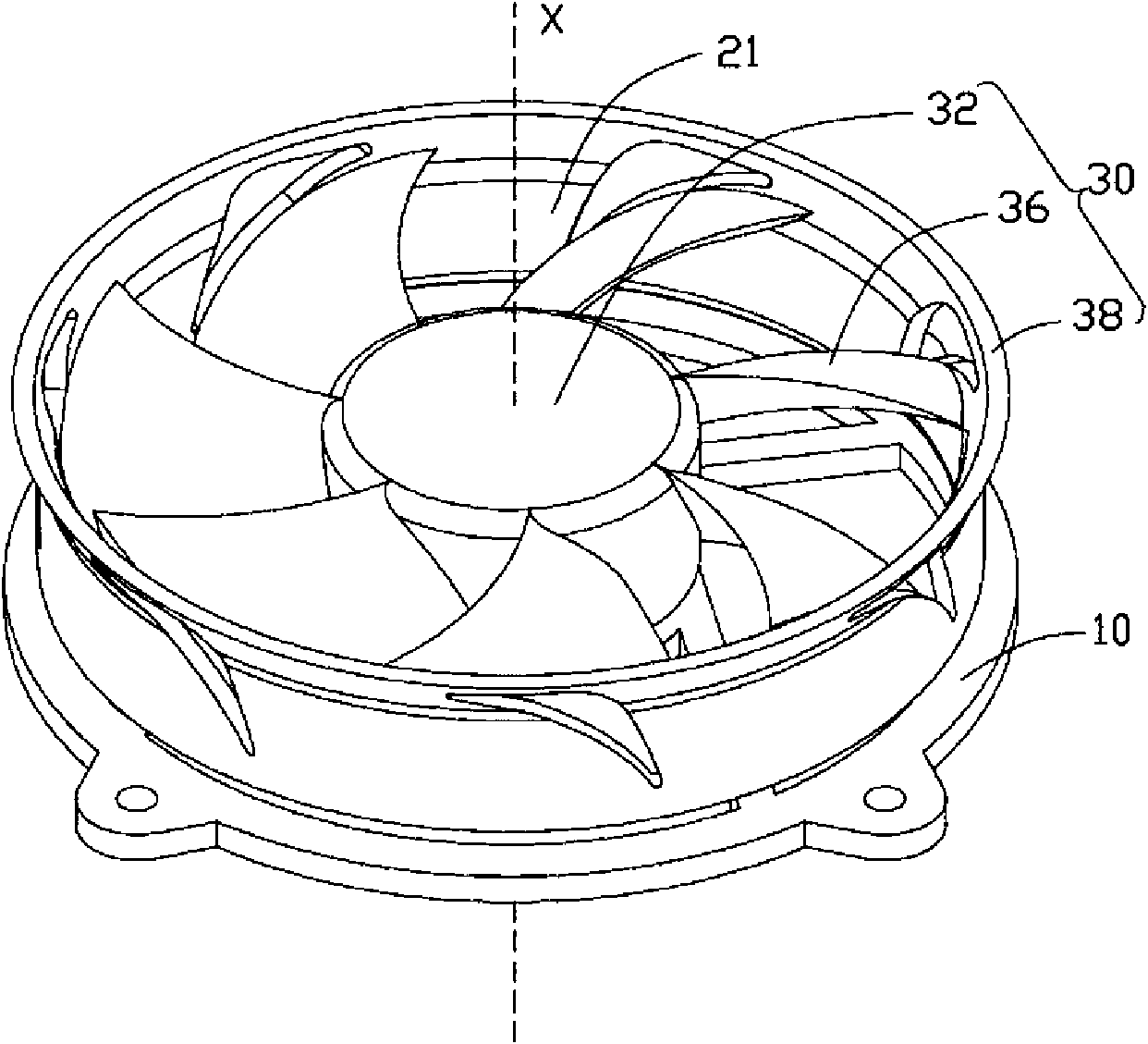

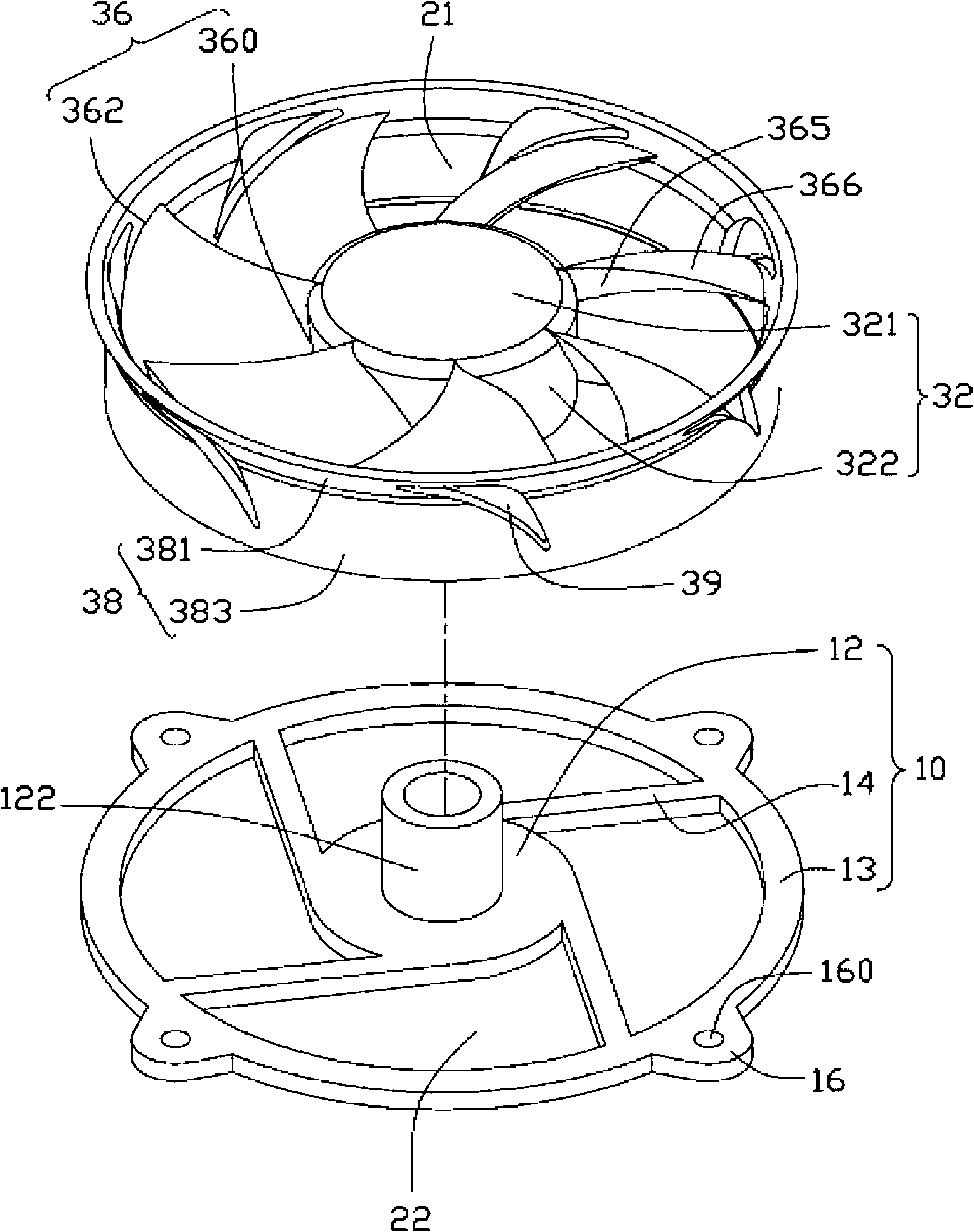

[0014] see figure 1 , the cooling fan includes a base 10, a stator (not shown) mounted on the base 10, and a rotor 30 mounted on the periphery of the stator.

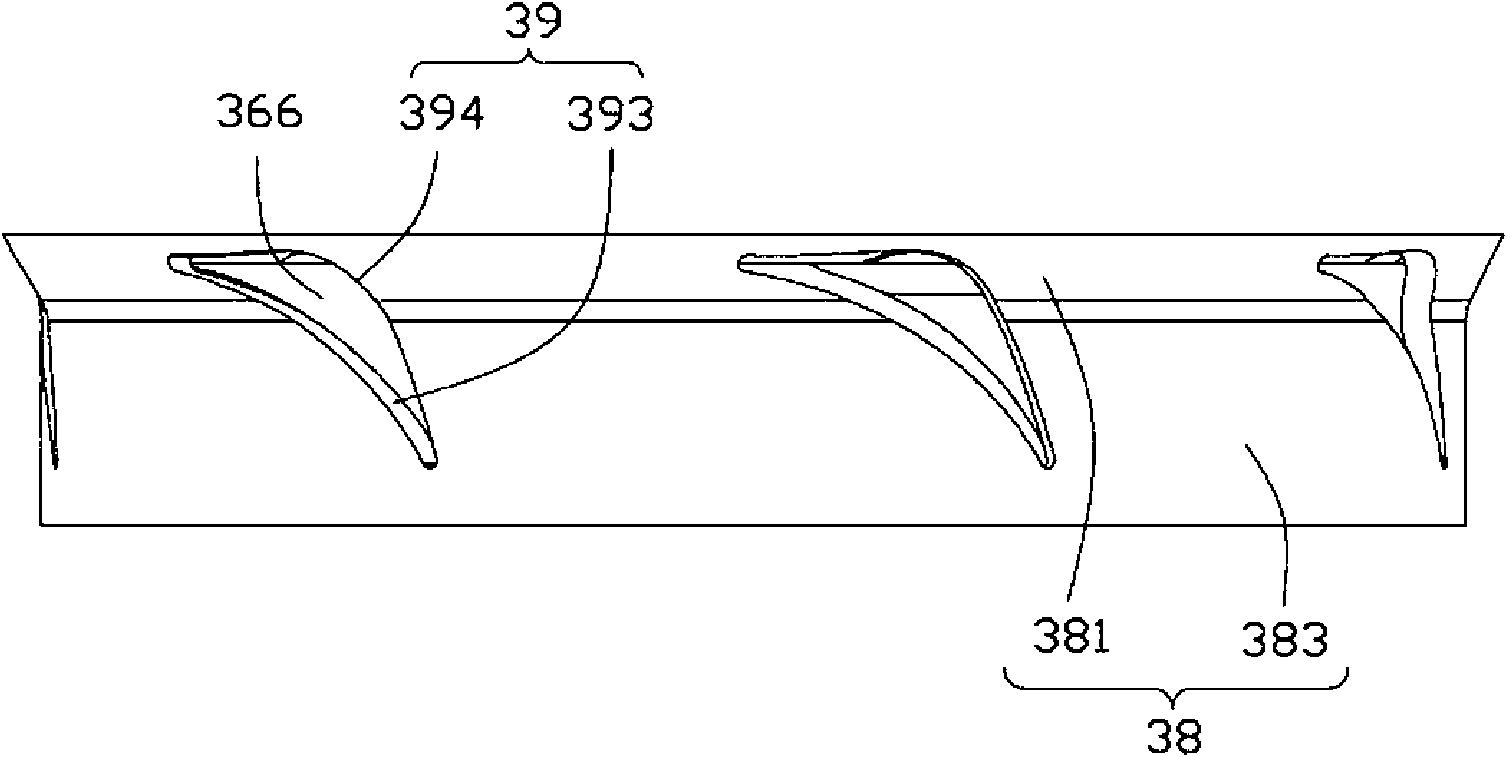

[0015] Please also see figure 2 The base 10 includes a circular support portion 12, an annular locking portion 13 spaced from and concentric with the support portion 12, and a number extending outward from the periphery of the support portion 12 to connect the support portion 12 and the locking portion 13. root ribs14. The base 10 forms an air outlet 22 between the supporting portion 12 and the locking portion 13 . The center of the supporting portion 12 protrudes upwards to form a central column 122 , and a bearing (not shown) is accommodated in the central column 122 . The locking portion 13 protrudes horizontally outward from the outer periphery to form a plurality of positioning portions 16 . The positioning portions 16 are arranged at equal intervals along the circumferential direction of the locking portion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com