High-speed broad-width paper-making felt needling device

A needling device and technology for papermaking felt, which are applied in the field of high-speed and wide-width papermaking felt needling, can solve problems such as affecting equipment stability, reducing product quality, and many times of needling, so as to improve operation efficiency, simplify operation, The effect of not easily damaging the blanket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

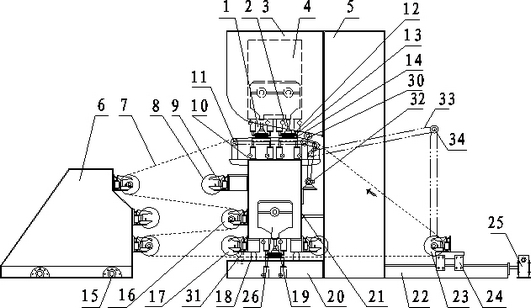

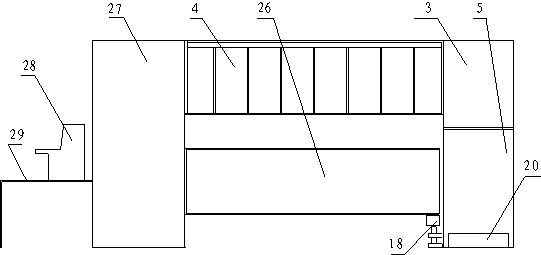

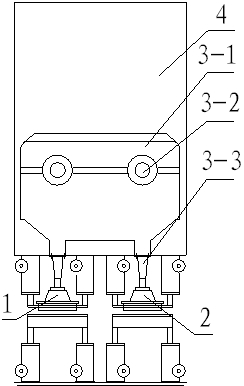

[0035] Embodiment 1: this acupuncture device has two main supports, one end is the upper and lower cloth end main support 5, and the other end is the operation side main support 27, and the upper end of the upper and lower cloth end main support 5 side is connected with an arc-shaped support 3, The lower end of the same side of the main bracket 5 at the upper and lower cloth ends is connected with a lower bracket 20; there is a carriage 6 in front of the main carriage, a clamping device 9 is arranged on the carriage 6, and a tensioning device is connected to the rear of the main carriage. There is a clamping device 9 on the device, and a blanket roller is connected to the clamping device 9; a main beam 4 is connected at the upper end between the two main supports, and the main beam 4 is fixed on the main support 27 on the operating side and the arc-shaped support at the upper and lower cloth ends 3; a suspension beam 26 is connected below the main beam, and the operation end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com